jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Jun 30, 2013 22:26:25 GMT

hi peter

the blower pipe should be attached to a proper blower ring around the blast pipe...what you have is a cheap and inefficient arrangement typical of cost cutting that none of us building our own locos would copy! the blast pipe nozzle also looks far too far away from the petticoat pipe for correct draughting... make up a cardboard template same diameter as the petticoat pipe with a 1:3 taper on it and slide down the petticoat pipe into the blast pipe nozzle... the top of the taper (where it departs from the parallel part of the template) should be about 3/16" into the petticoat pipe before it forms a flare.

cheers,

julian

|

|

|

|

Post by peterdebeus on Jul 1, 2013 9:17:39 GMT

Thanks again Julian!

I will see if i can find a ring blower that fits my loco.

Should be lot easyer to get it on its working pressure i assume.

I was just wondering for the time being, what the best position would be to place the pipe so i can test fire it and test the injectors with the now moddified pipework.

Thanks!

Peter

|

|

|

|

Post by Deleted on Jul 1, 2013 10:52:18 GMT

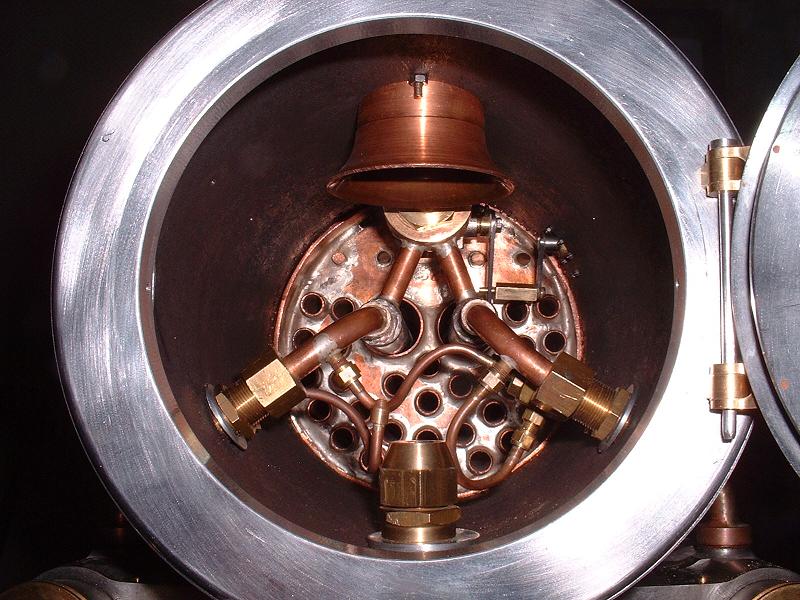

Hi Peter I have the same single-nozzle blower on my Britannia, but it's mounted lower down alongside the blastpipe. This photo shows the arrangement. It works well enough for me - I switch from electric fan to blower at 20psi and it then lifts the pressure very quickly. Certainly worth trying before you go to the trouble of fitting a ring blower.  Regards, John |

|

|

|

Post by peterdebeus on Jul 1, 2013 11:44:48 GMT

Hi John, Thank you, i will try this first and see what happens  Peter |

|

|

|

Post by Rex Hanman on Jul 1, 2013 14:04:46 GMT

We have the same arrangement on our club loco. Works fine but you can easily knock it off alignment when sweeping the tubes, so if your blower suddenly seems less effective check that it still points in the right direction.  |

|

|

|

Post by peterdebeus on Jul 1, 2013 21:45:41 GMT

i will keep an eye on it  |

|

|

|

Post by peterdebeus on Jul 3, 2013 6:59:10 GMT

yesterday i tried to put some petrolium trough the cylinders because when spraying oil in there

there was a lot of brown stuff comming out of the cylinders.

(I Always use petrolium to clean engine parts when rebuilding engines, and it works realy well!)

I was pushing it forward and backwards a few times till the point where it blocked the whole time.

after about 30 times it was suddenly loose and it could turn all the way round forward and backward, even on the verry verry slippery peace of track with all that oil on it the wheels turn

by only pushing the engine forward. (at first i had to turn the wheels by hand).

There was a lot of thick brown stuff comming out of the cylinders so i think it was just rust in

there, put another 250ml of petrolium trough to make sure its clean inside now.

Thats a big step forward to me!

|

|

|

|

Post by Deleted on Jul 3, 2013 15:04:01 GMT

Hello Chaps----- PETER, that's good news indeed BUT, ---- BE CAREFUL !!---- I'm not sure what Modelworks used for piston rings (Either main or valves)... If it's o-rings then you really don't want to tear them.. Might I suggest that you remove the cylinder front end covers and take a more detailed look at what's going on in there ?? I know it's going to be a bit of a pain, what with the running boards coming as close as they do.... OR}--- you might try FLOODING the whole set-up with a penetrating oil (WD40 or similar) --- it's a bit less drastic than petrol but will help loosen any remaining rust, get it flushed away, and leave a lubricating film on the cylinder walls as well.........

|

|

|

|

Post by peterdebeus on Jul 3, 2013 20:27:46 GMT

I already did, i only used the petrolium to flush it, and after that i sprayed half a can of wd40 in there to lubricate it. and after that normal oil  I had already removed the front covers some time ago to try and see if the cylinders where upgraded (some pages ago you can see the pictures.). Atleast they have made the steam ports inside bigger, and all the motionwork on my engine was changed for better quality. So i can be almost sure that the piston rings where also upgraded as they where also a known weak point. Think the problem was that i only cleand the part that you can see with the front cover removed, so behind the piston was a lot of dirty stuff. thats why it made only half a stroke (thats what i think). I am now drilling an endless amount of 1.5mm holes for locking the motionwork.. pfffffff Have ordered split pins, steam oil, brushes, and a lot more small stuff at maidestone. Lot cheaper than buying over here... |

|

|

|

Post by Deleted on Jul 4, 2013 8:39:40 GMT

Hello Chaps--------- Ah, I'd forgotten about that photo..So when you were referring to the loco coming up against a "stop" of some kind it would have been in the rear part of the cylinders then ??---------- Oh well, at least you now know what it was....Good chaps at Maidstone Eng.---- Why not give yourself a well deserved treat and come over to visit York Railway Museum whilst the A4 collection is here ??

|

|

|

|

Post by peterdebeus on Jul 4, 2013 13:24:02 GMT

till when will that be possible? , just had my holiday  But maby i can come over for a weekend! |

|

|

|

Post by peterdebeus on Jul 4, 2013 21:33:09 GMT

tried to run it on air tonight but nothing happend, not in forward gear and not backwards.

Also tried to push it a bit forward and backward with the regulator fully opend, but i cant feel any difference with

the regulator opened or closed.

Only thing is that there is a lot of air comming out of the chimney, not sure if that is ok?

|

|

bhk

Part of the e-furniture

Posts: 458

|

Post by bhk on Jul 4, 2013 21:59:30 GMT

Sounds like either the valve or piston rings / o-rings are leaking past

|

|

|

|

Post by peterdebeus on Jul 4, 2013 22:13:41 GMT

think its time to take them out to inspect them...

|

|

|

|

Post by peterdebeus on Jul 7, 2013 7:33:50 GMT

yesterday i did some work and took one of the piston and valves out. I made some pics, dindnt clean them or did anything, this is how they came out. Hope somebody can say if this is origional and if it looks ok, (ofcoars it needs to be cleaned). Attachments:

|

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Jul 7, 2013 8:39:59 GMT

hi peter,

i am afraid i am at a bit of a loss to know how to politely describe your piston and piston valve pics.

as indicated in my post of 6th march, i think a complete strip down of your loco is required. heavens knows what other horrors will be revealed that are preventing the loco from working properly, though a trawl through some of the modelworks/winsons blogs and threads do not suggest you have an easy or quick job on your hands.

cheers,

julian

|

|

|

|

Post by Deleted on Jul 7, 2013 9:00:00 GMT

Hi Peter The main piston with two split rings looks the same as my Britannia and should be OK, but the valve piston looks very odd. I don't understand why there is a wide groove in the middle of the brass ring, and the diagonal slot in the ring looks as though it will not close up completely when the ring is compressed. I think that the problem will be leakage past these rings. This photo  shows the PTFE rings that Doug Hewson made for the Winson Britannia, and if you can get someone to make similar PTFE rings to replace the brass ones then this would solve the problem. Kind regards John |

|

|

|

Post by peterdebeus on Jul 7, 2013 10:12:21 GMT

Hi Julian, A lot of work was already done, i replaced al the check valves, steam valves, refitted all the pipework. The motionwork was decent build, ( a realy experienced model builder has checked this for me.) This are not the origional items from modelworks anymore. One of the only things i didnt do, (and difficult to check from the outside), was the pistons and valves to inspect them. as lot of people told me just try if it runs, and if not you can still take them out to inspect them. I know there is still loads of work to to, but also a lot that was already done  John, I have the same idea, the piston fits quite tight in there, and it al feels ok to me (will let somebody check this). Will see if somebody can make new valves rings for me, and maby replace the main piston rings to PTFE to. Save's a lot of trouble wen lubrication gets low or when standing for longer times. |

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Jul 7, 2013 14:31:48 GMT

peter,

the finish of the pistons and their rings is far from satisfactory. john has made a really good job of his loco but only after lots of very hard work and within a timescale that most of us build a loco from scratch. what you have to remember is that all those machining marks on the pistons and the rings will quickly wear off in service leaving a not very satisfactory fit. PTFE is all well and good for the piston valve rings but the heads should still be a really good fit with no machining marks. that being said, i would expect your chassis to run on air ok as built (but not ok for hard work) and there is obviously a lot of internal friction somewhere if the wheels wont even turn around (assuming the valvegear is correctly set). my STEPNEY loco ran very well on air on just one cylinder with no packing! there is no mechanical friction to soak up valuable energy on my locos. a 9F should be able to pull about 15/20 people and tackle gradients with ease. as you have described, yours wont even turn it's wheels around without a load!

cheers,

julian

|

|

|

|

Post by Deleted on Jul 7, 2013 14:59:36 GMT

Hi Julian I agree, it ought to run on air even with some leakage. Mine would run on a single cylinder on 20psi even before I replaced the valve piston rings with PTFE - see www.britanniabuilder.com/kit13.htm#label2 , despite the significant leakage. Peter, what sort of compressor are you using? Kind regards John |

|