|

|

Post by Oily Rag on Jul 1, 2018 22:00:37 GMT

Last Wednesday I took the day off, drove up to Gympie and with two others I started my RM2000 driver training. The happy snap is some of the Mary Valley Rattler staff and volunteers and three of us RM2000 pupils. These railmotors are 50 years old now and I think they are marvelous. I grew up riding these up down the Ferny Grove line on weekend services and even back in the 70's a cab ride from Gympie to Brisbane. ( Kind driver) Who would have thought 45 years later I would be learning to drive these for trips down the Mary Valley branch. A long way to go, I have just started the basics of the familiarisation with the units and cold and hot starts etc. Lots of unique things to learn.

Some love these units, some detest them, I am falling in love.

One lives for this stuff !

|

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on Jul 2, 2018 2:35:12 GMT

Sounds like fun Dazza, I've a few good memories of the 2000 class; we used to take one from Laidley to Ipswich back in the 80's, mum and I off to do the shopping. Then we'd go home on 'the red rattler'; a diesel hauled rake of wooden Evan's cars. The twists and turns of the Little Liverpool Range were always a fun journey.

I got a cab ride of sorts on one in the mid 90's too; mum had arranged a trip on the Savannahlander up north (before the journey was extended out to Cairns), which had (still does I believe) refitted 2000 class railmotors. The insides had all been redone for the tourist trip, with the cab wall removed to improved the views; but I got to sit in the off-side seat in the 'cab' for a while on the return journey.

|

|

|

|

Post by Oily Rag on Jul 8, 2018 4:12:48 GMT

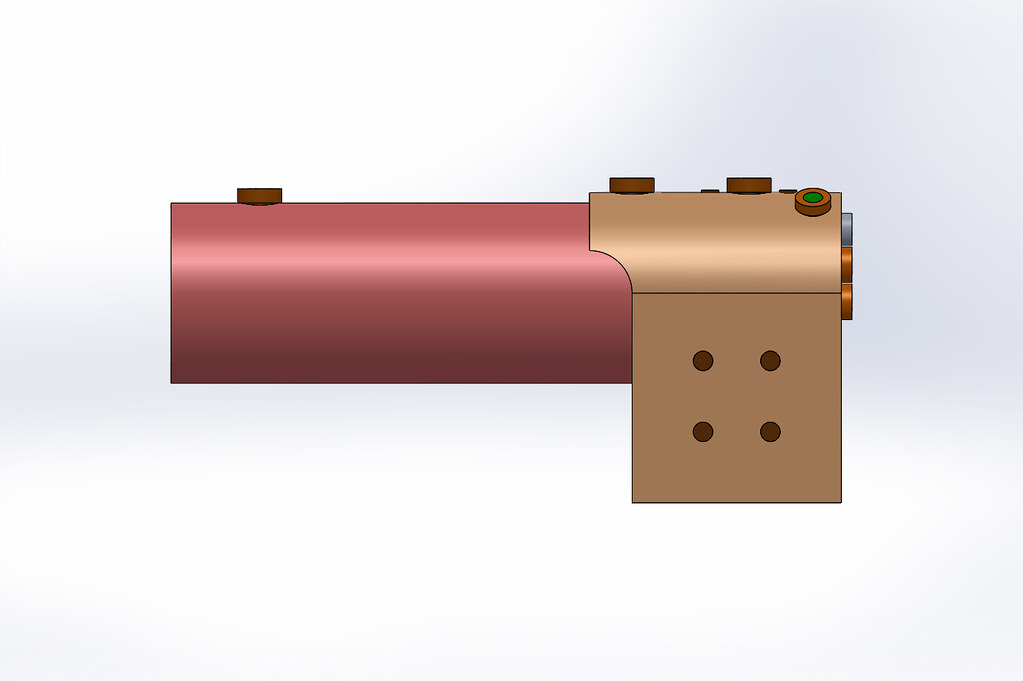

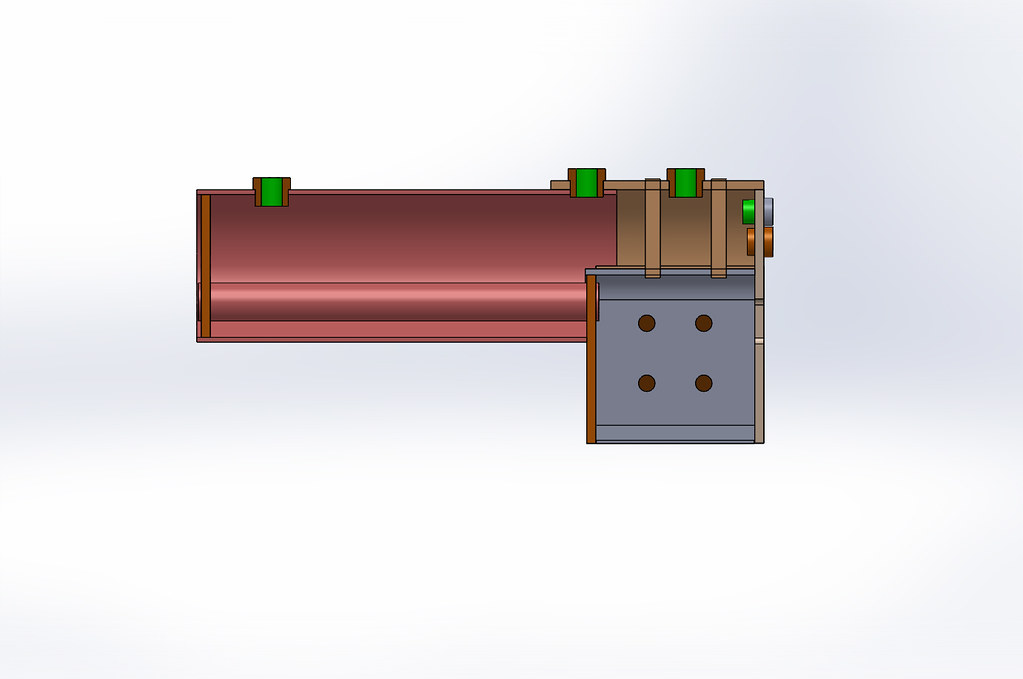

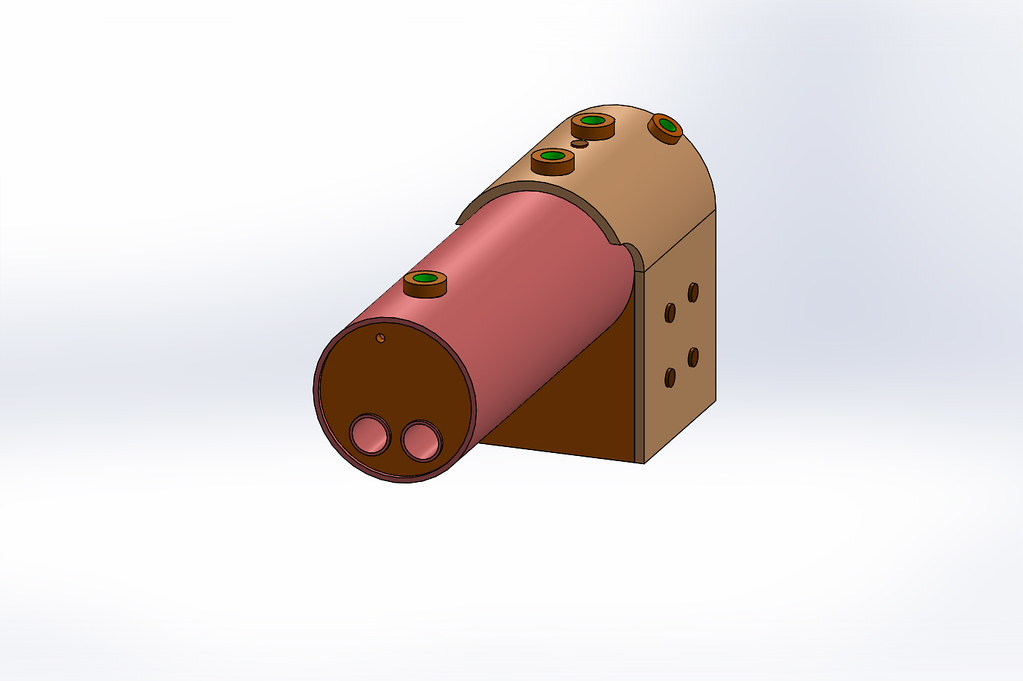

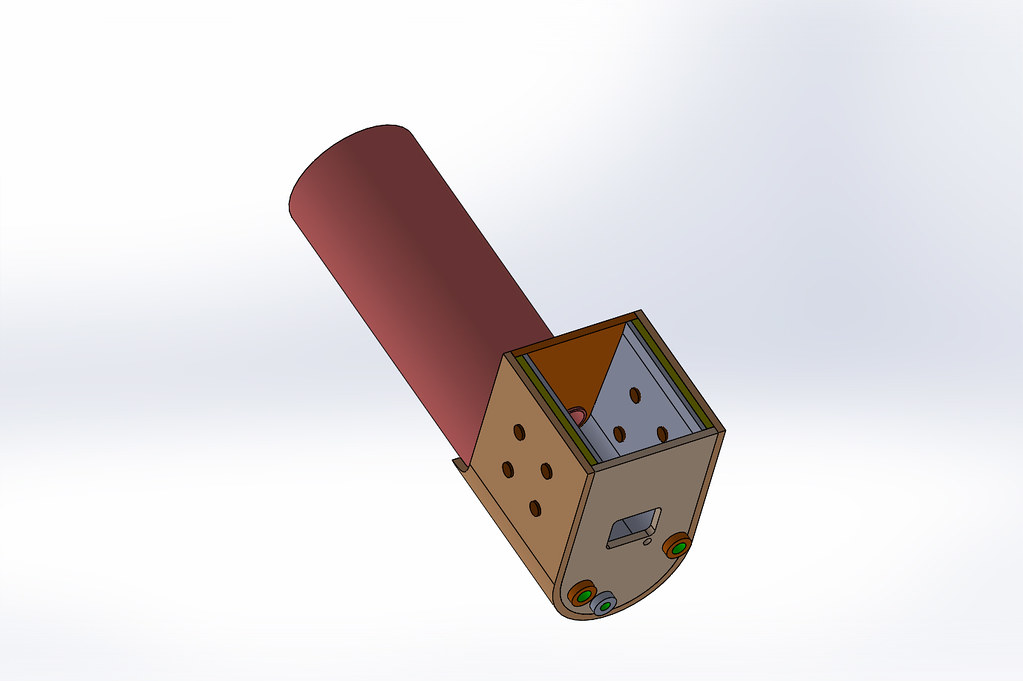

Working up my boiler drawings to take to Mr Inspector. The usual 3D then to 2D working drawings. I am blind in one eye and I cannot see out the other, but going over the AMBSC Code Part 3 Issue 2.00- 2017 Sub- Miniature Boilers , I cannot find a mention at all about barrel wall thickness. Only part 2.3.2 which mentions Max diameter 63.50m . No mention of wall thickness to comply with. :scratch: I will be using 1.60mm wall, 50.80mm diameter. The original drawing which was in the May/June Issue of Australian Model Engineering has a barrel wall of 1.20mm.      |

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on Jul 8, 2018 7:10:46 GMT

That's a nifty looking little boiler.

IIRC, the minimum wall thickness is calculated from the intended working pressure, so there should be a table or equation or something in there. Having said that I've not looked at the sub-miniature code, so could be wrong.

Is that wet side walls, and dry front and back? Have you considered having a removable firebox rear? I've seen others mention it's handy for getting the grate out, shovelling the fire out, and you can clean the tubes from the firebox end rather than trying to work around everything in the smokebox. Dad's 5" loco's all had Briggs steel boilers, and we had removable rear plates on the firebox on them; came in handy when one boiler developed a leak in one of the tubes, as it was able to be repaired overnight without removing the boiler from the loco. Though that's hopefully not something you'd need to worry about!

As an aside, if you did want to go for the original 1¾" diameter, there's copper tube available from the UK.

P.S. Any chance I could pinch a copy of the boiler plan once it's approved?

|

|

|

|

Post by Oily Rag on Jul 8, 2018 22:30:49 GMT

That's a nifty looking little boiler. IIRC, the minimum wall thickness is calculated from the intended working pressure, so there should be a table or equation or something in there. Having said that I've not looked at the sub-miniature code, so could be wrong. Is that wet side walls, and dry front and back? Have you considered having a removable firebox rear? I've seen others mention it's handy for getting the grate out, shovelling the fire out, and you can clean the tubes from the firebox end rather than trying to work around everything in the smokebox. Dad's 5" loco's all had Briggs steel boilers, and we had removable rear plates on the firebox on them; came in handy when one boiler developed a leak in one of the tubes, as it was able to be repaired overnight without removing the boiler from the loco. Though that's hopefully not something you'd need to worry about! As an aside, if you did want to go for the original 1¾" diameter, there's copper tube available from the UK. P.S. Any chance I could pinch a copy of the boiler plan once it's approved?

I will be most happy to share the drawings with you or who ever when all is sorted, then proven. I had created 2D GA drawings and 2D drawings of the boiler parts yesterday to take to Mr Inspector. |

|

|

|

Post by Oily Rag on Jul 11, 2018 22:03:41 GMT

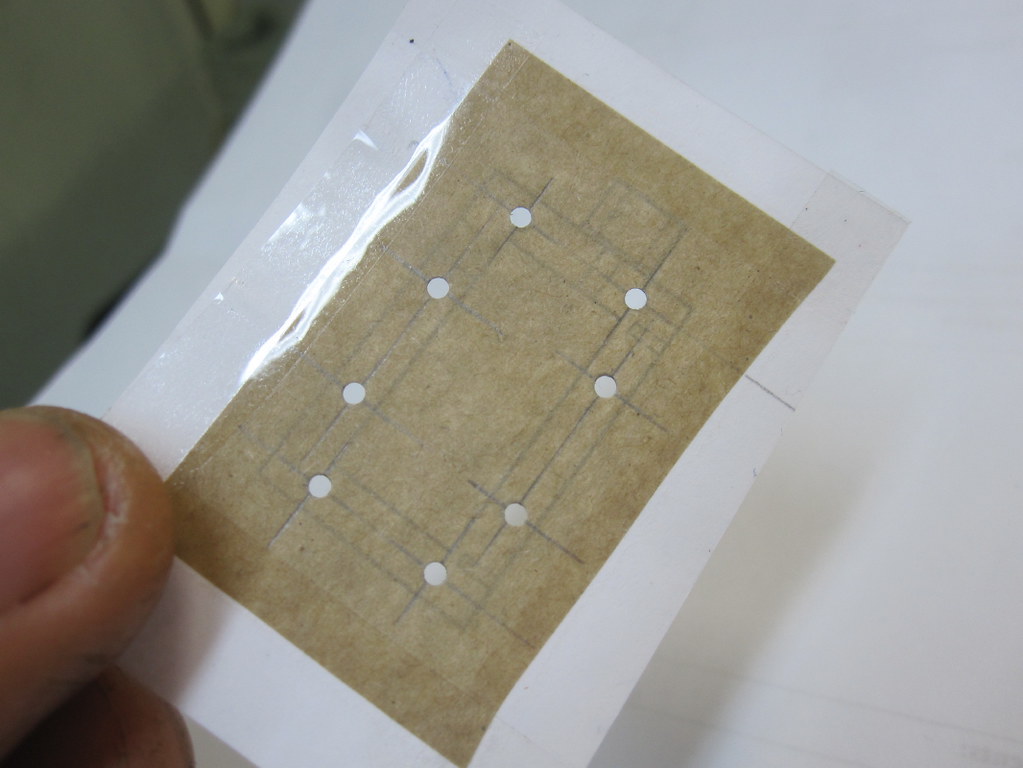

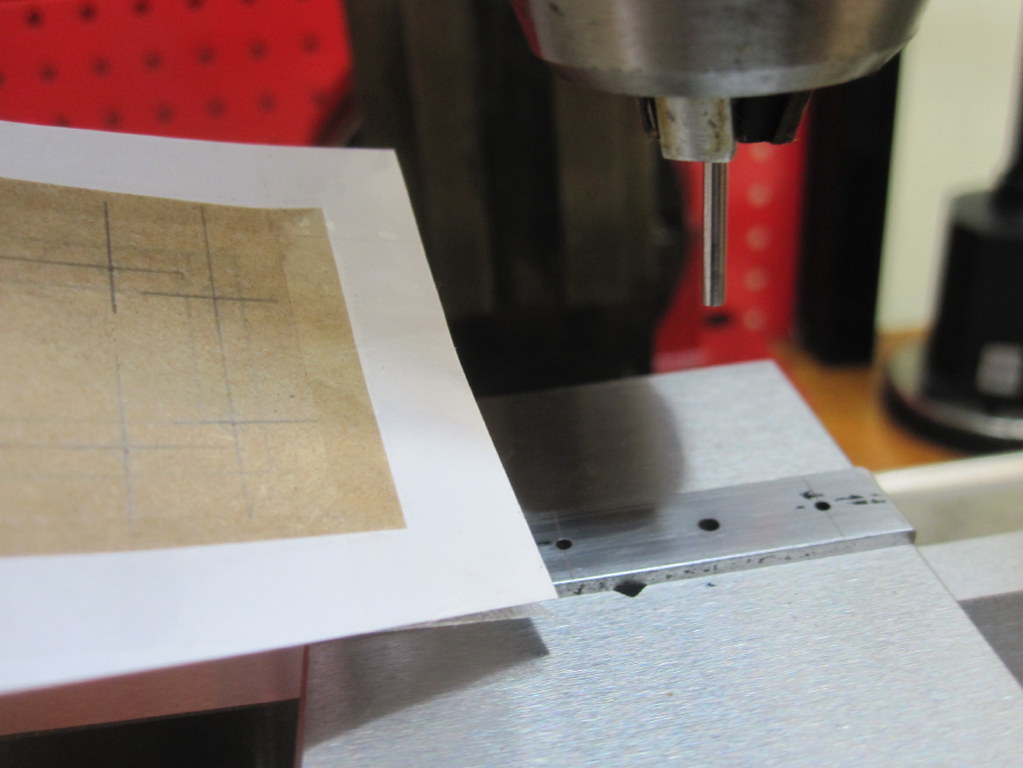

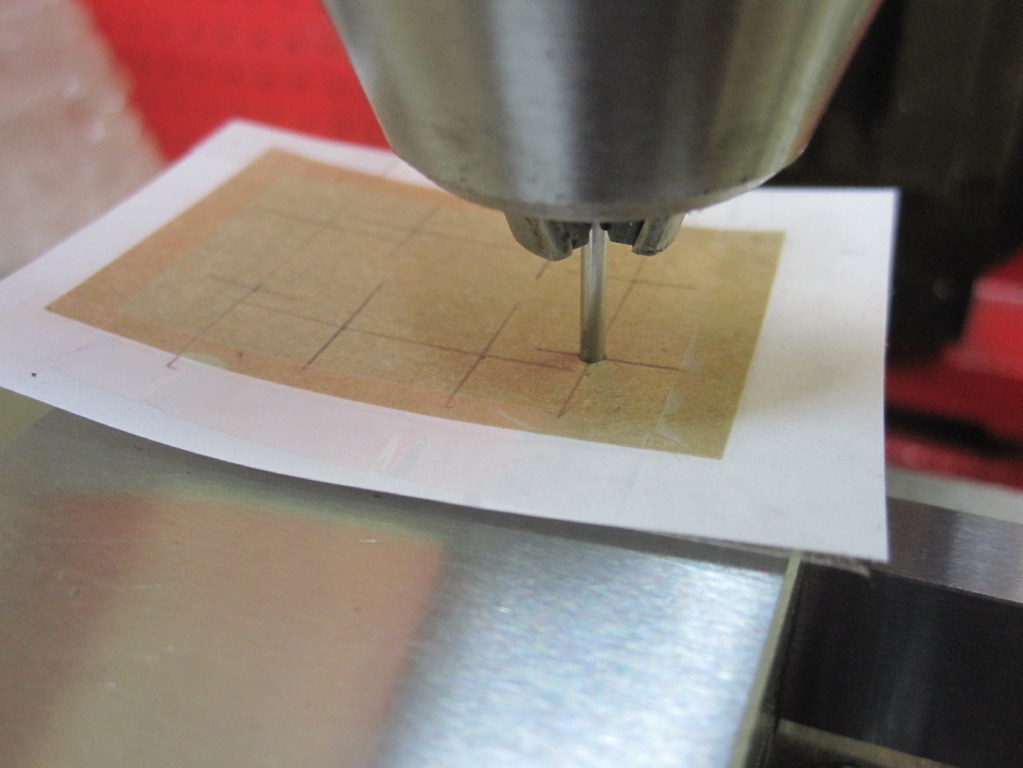

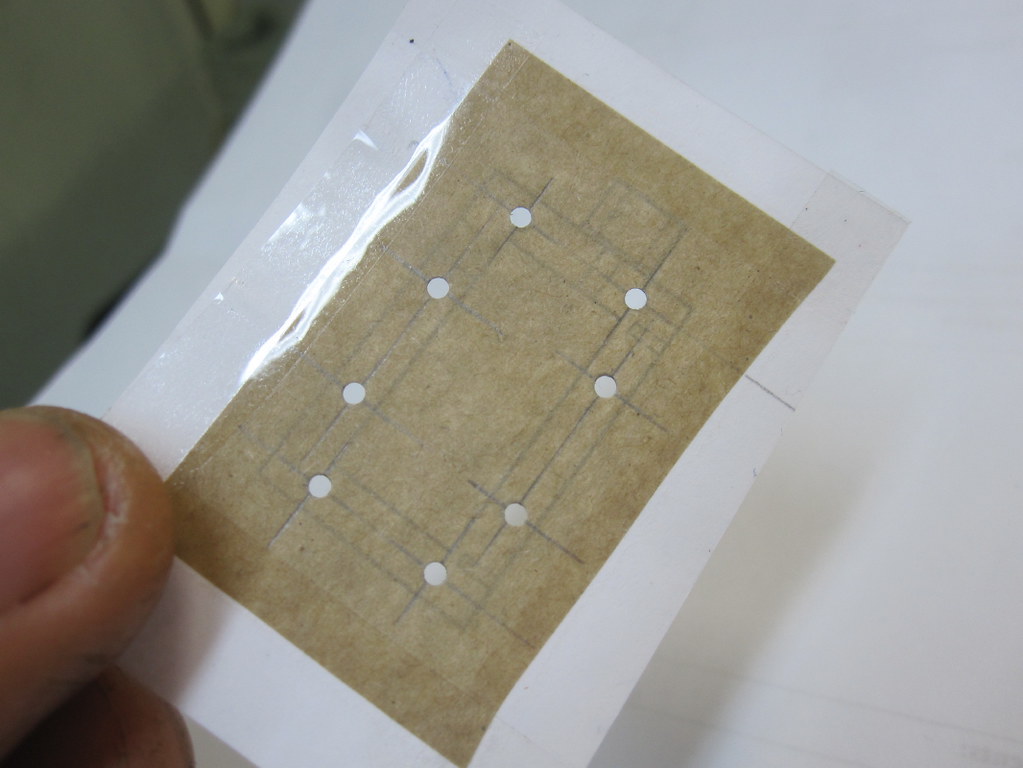

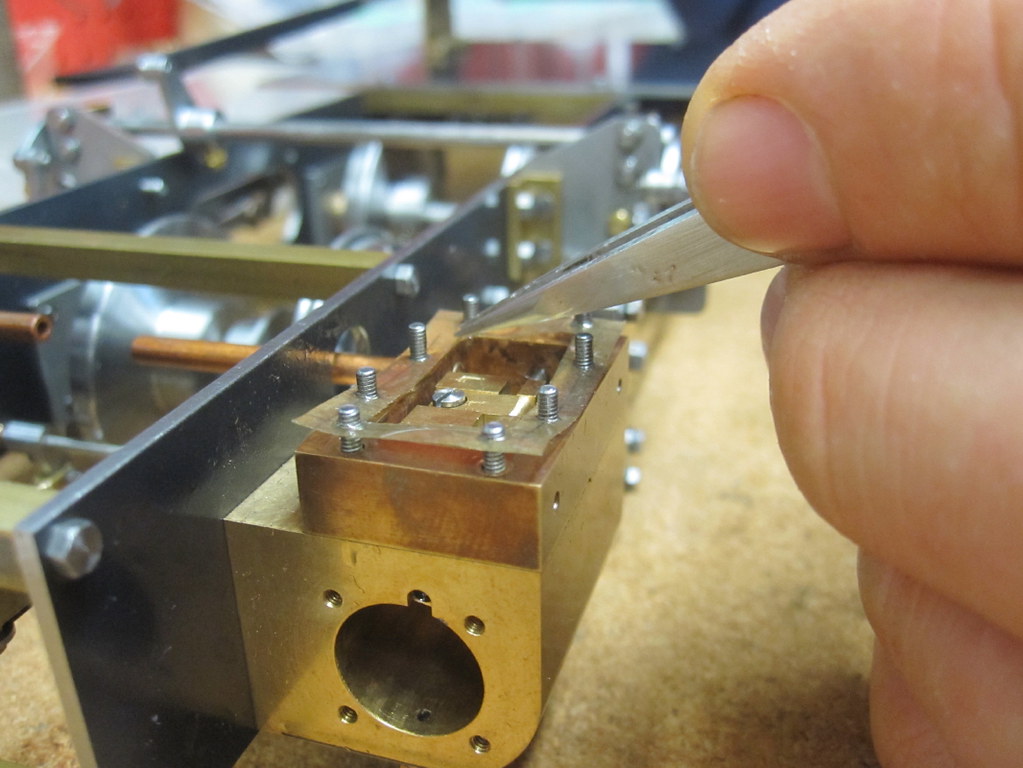

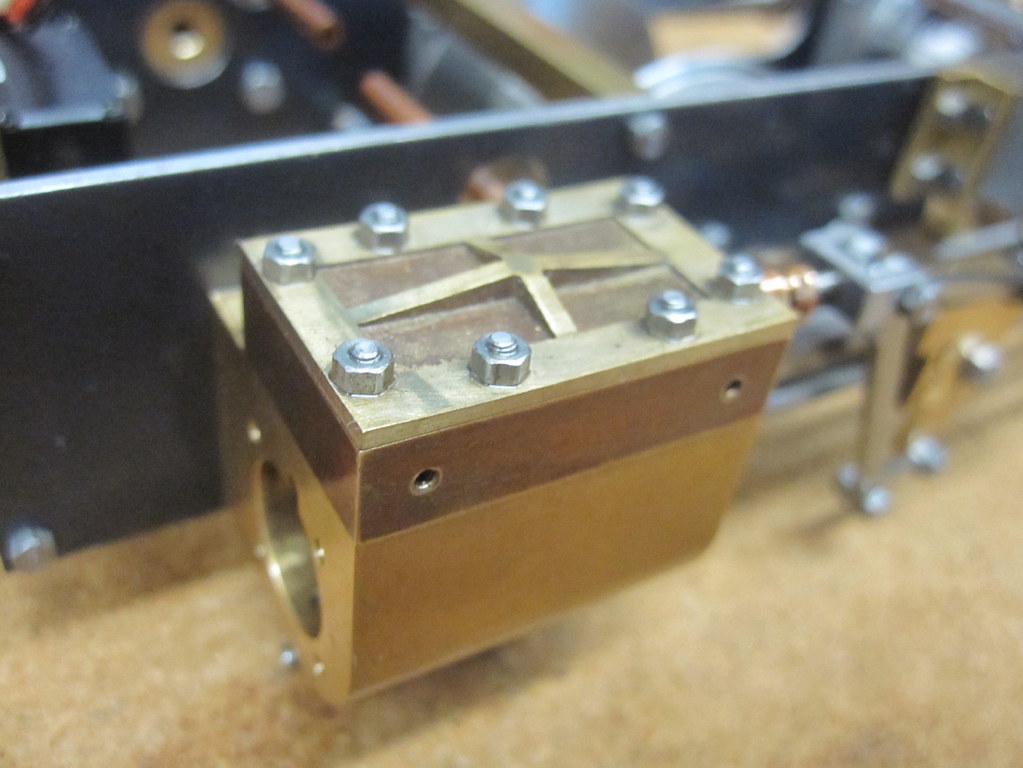

Yesterday I took the afternoon off and caught the Sparky into town and attended a presentation of the "Sydney Mail" by Queensland Rails rail historian Greg Hallam. Met up with friends and after we paused at a cafe to tell stories where I noticed the brown paper bags for placing slices of desert into. I requested one paper bag along with my cup of tea, tossed some extra coin into the tip jar. After dinner, in the Red Room the paper bags use is realised. It was .06mm thick when dry. Print off the steam chest over and front cylinder covers in 1-1 scale. Some cello tape. Line up one of the previously made shim punches in the little mill Drill. (1.70mm for the 10 BA, 1.75mm would be better if I was into production mode) . Pressed some holes, then out with the sharp pointed scalpel. An oil soak and then fitted up the chest covers. It was fun.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Jul 12, 2018 17:50:13 GMT

Hi Darrell

Silly question,if I may, but I am at this exact point on my Hunslet build.

Why not use spring washers (and even flat washers as well) under the nut heads to retain (and spread) clamping load?

Cheers

Malcolm

|

|

|

|

Post by Oily Rag on Jul 12, 2018 21:42:22 GMT

Hi Darrell Silly question,if I may, but I am at this exact point on my Hunslet build. Why not use spring washers (and even flat washers as well) under the nut heads to retain (and spread) clamping load? Cheers Malcolm |

|

|

|

Post by Oily Rag on Jul 12, 2018 21:44:34 GMT

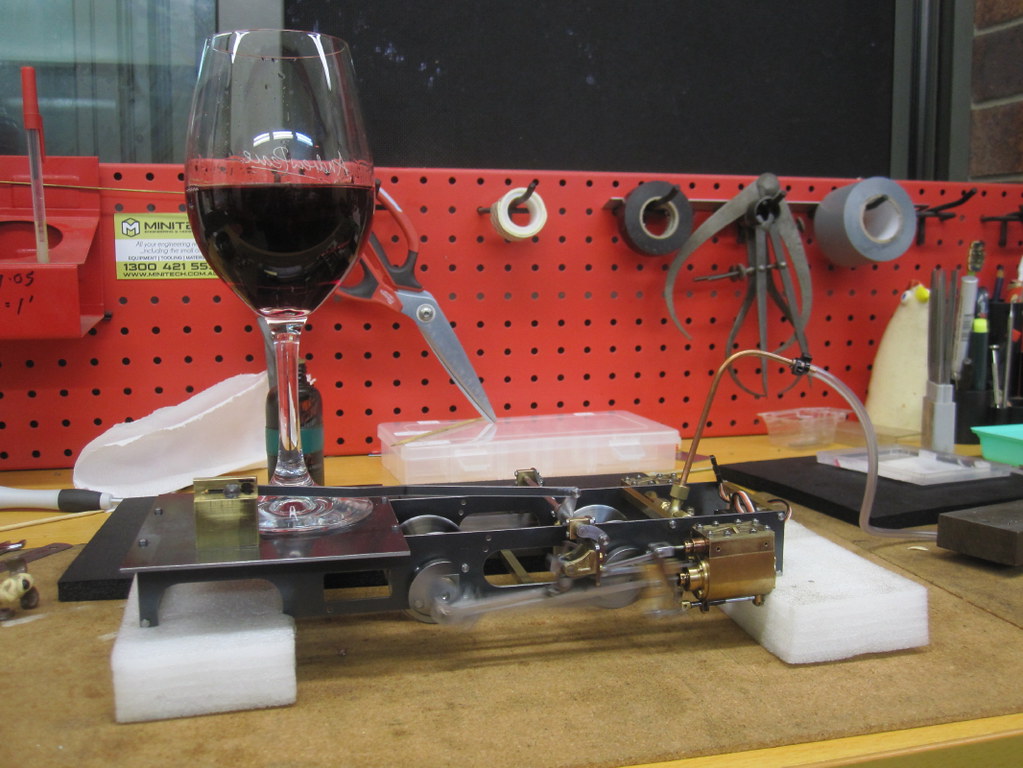

ABC jazz digital radio is on low, we have eaten and showered, MAM is down the corridor in her art room watching a utube on how to fit the Slomo to her Lady Ann frames. I click and drag the 3D model onto the 2D page a few times. I print this off. I ponder and experiment a few times, settle on a process and away I go. The results seem to have worked. It was all simple. The punch is made from a drill shank and a previously drilled piece of steel, used for making holes in brass shim. It was relaxing, enjoyable and a nice result. That is satisfying. That is fun. More fun to be added maybe next Tuesday as a good friend of mine does the hot test of # 967's new welded boiler and I will be attending, learn a bit more about the testing process and I will get to toss some black stuff onto its grate. That will also be fun, even if I have to get up at 3.30am and drive for 2 hours to be there for the match to be tossed in and after a long day of fun, the drive home again, but the drive home goes well as one reflects on the day and the things learned. The day will surely be chased with a couple of glasses of evening red.  |

|

|

|

Post by Oily Rag on Jul 12, 2018 21:57:57 GMT

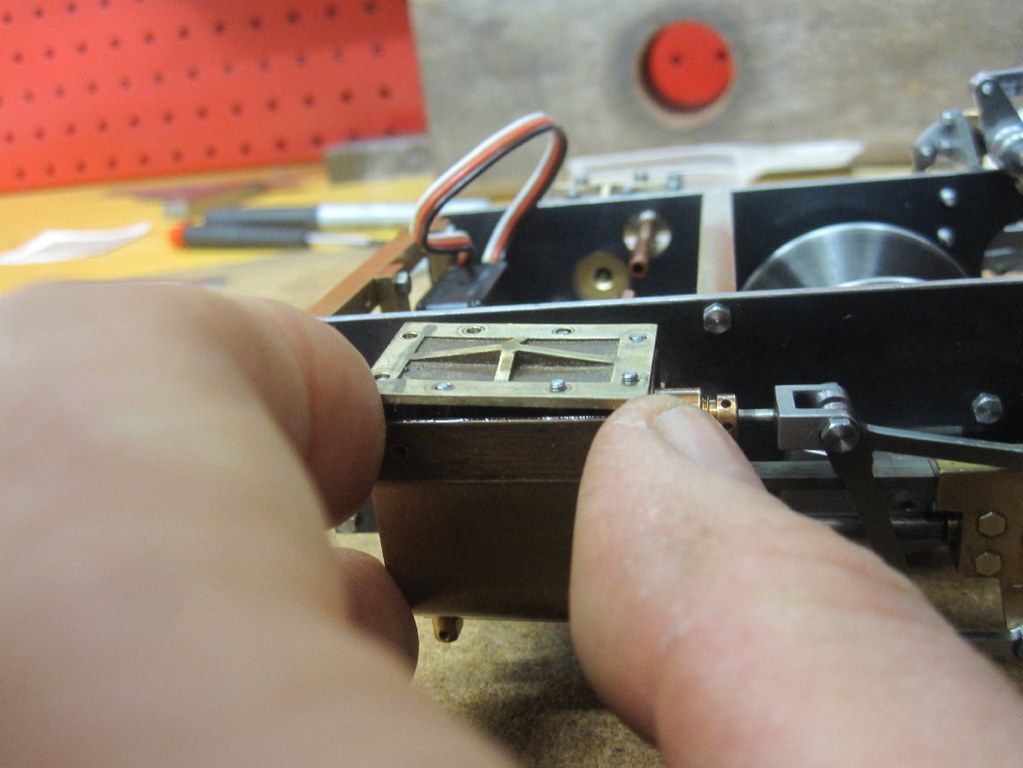

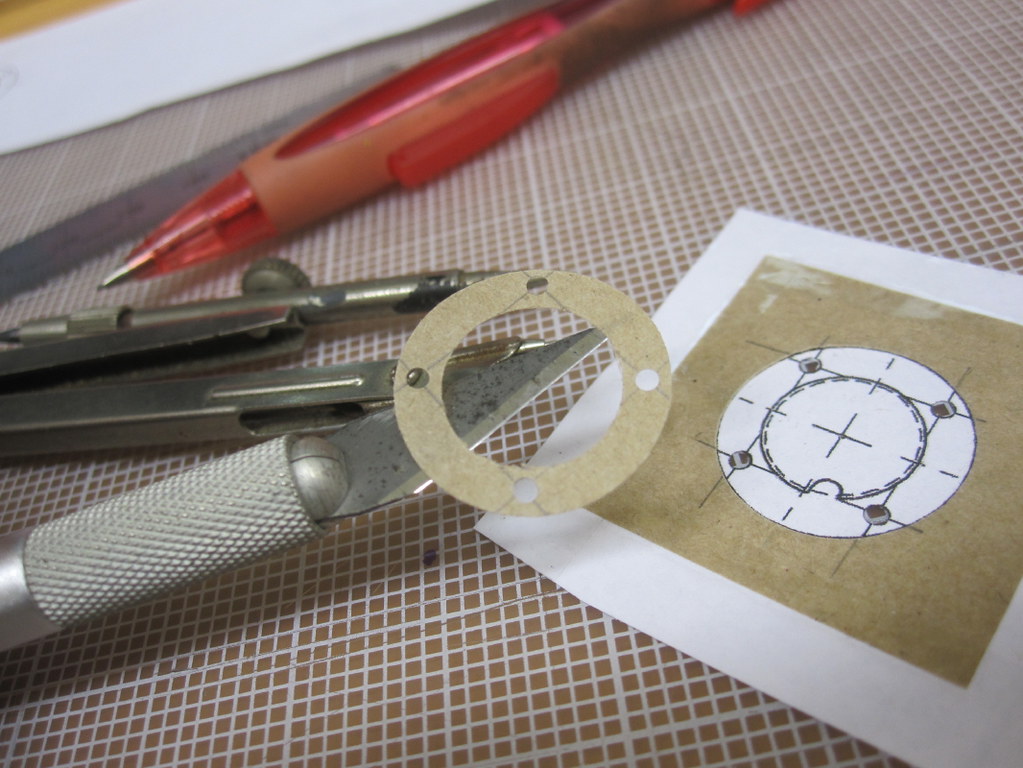

Not a lot done last night, phone calls, customers and heritage railway related, however the front cylinder covers gaskets were cut out and the covers were fitted.

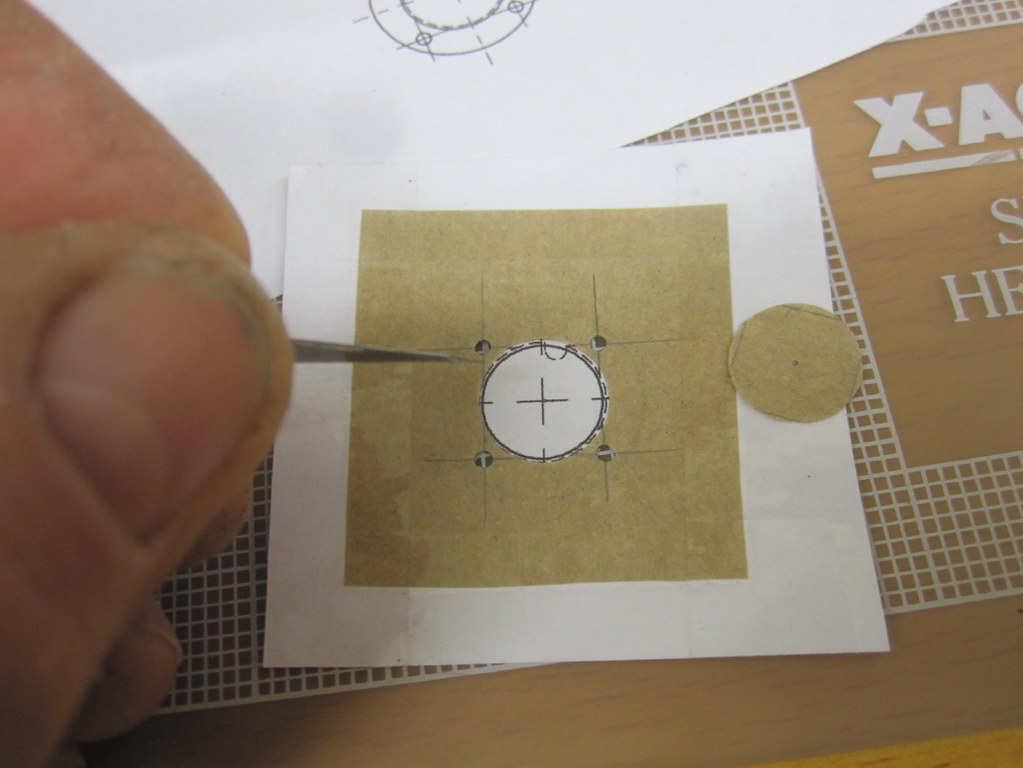

I read in the book that Brian Wilson suggests setting up the exhaust T before the steam T, I take heed of this and as I have not made the exhaust T I will start spinning some brass in the Myford tonight, before I knock off to watch Endeavour. (the only TV I watch all week) Maybe this weekend will be the air test. I used an old compass that kicks about the workshop that I used circa 1978 during my schools days, I sharpened one the points to be a bit knife like and used it to scribe the circles, then a touch up with the Exacto scalpel. I used an old compass that kicks about the workshop that I used circa 1978 during my schools days, I sharpened one the points to be a bit knife like and used it to scribe the circles, then a touch up with the Exacto scalpel.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Jul 13, 2018 7:18:42 GMT

Hi Darrell "Because those in the cheap seats will be making the sign of the cross and crying out "not prototypical" How stupid of me. Of course, I forgot about "rivet counters". I will wear sackcloth and ashes for the rest of the day and force my self to watch Kuldeep Yadav take 6 wickets for 25 runs in the ODI at Trent Bridge as penance. Regards Malcolm

PS Nice gaskets,BTW.

|

|

|

|

Post by Oily Rag on Jul 13, 2018 21:05:58 GMT

Hi Darrell "watch Kuldeep Yadav take 6 wickets for 25 runs in the ODI at Trent Bridge as absolution." Ochhhhhhhhhh

|

|

|

|

Post by Oily Rag on Jul 14, 2018 23:03:05 GMT

|

|

|

|

Post by Oily Rag on Jul 15, 2018 0:20:05 GMT

MAM arrives.

I have much apprehension, almost to the point of procrastination, but no rush, never rush and trip over on the last step and thus bite the dust.

Cameras ready.

Full forward is set.

I open the air valve,

Away it races, whoooooooo.......................

Quickly close the air valve. The realisation it actually goes sinks in, yells of

"it lives, it breathes, rise, rise"

I just needed some lightening strikes and a fierce summer storm with the lightening flashes lighting up the Red Room via the sky lights and a better Dr Frankenstein movie voice.

I open the valve gently and away it goes, back it off, the valve is a bit on and off, the workshop compressor is set to 90 psi (the bike workshop an air line is plumbed to the red room), so get a G clamp and simply throttle the nylon tube.

Chugga chugga chugga chugga.........................................................................................A short 10 second video is here, www.youtube.com/watch?v=Jt5i34nWlFE&feature=youtu.be The workshop crew all gather around The workshop crew all gather around Forward works, into reverse, yep, just as good Forward works, into reverse, yep, just as good

Ponder, will it notch up ? Yep, will work on air with the die block 1/3 travel in the link, as per what the CAD model and the Docstader confirmed. Yep, will work on air with the die block 1/3 travel in the link, as per what the CAD model and the Docstader confirmed.

I am chuffed with myself, because I considerably redesigned the published valve gear layout after much consulting of text books and CAD models and the Doctrader valve gear simulator. That was a lot of work and over heating of my brain cells. The story of that is earlier in this thread.

Much Red was consumed last night, just watching it.

|

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on Jul 15, 2018 4:03:37 GMT

A momentous occasion, well done Dazza!

|

|

44767

Statesman

Posts: 539

|

Post by 44767 on Jul 15, 2018 5:23:15 GMT

Well done Darrell; you're a very clever man.

|

|

stevep

Elder Statesman

Posts: 1,073

|

Post by stevep on Jul 15, 2018 7:37:42 GMT

Great - I've been waiting for this day. Well done.

|

|

|

|

Post by Oily Rag on Jul 15, 2018 9:52:04 GMT

Thanks every one for your nice responses, they are much appreciated.

|

|

|

|

Post by mr swarf on Jul 15, 2018 10:03:21 GMT

Cracking work Gromit.

|

|

don9f

Statesman

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Posts: 961

|

Post by don9f on Jul 15, 2018 20:24:09 GMT

Sorry I’m a bit late....but a fantastic achievement !👍

Cheers Don

|

|