|

|

Post by Oily Rag on Oct 14, 2018 21:59:13 GMT

Dazza Just been reading your thread and it is an inspiration to a novice. As you will have seen there may be two Aspinal boilers in the make so I will be reading your thread a few times! Thanks David

I am a novice as well.

I was an armchair reader of ME mags etc for many years while I sorted life, home and work and now is the time to enjoy ME and full size choo choos, because if I procrastinate any longer I will run out of time. |

|

|

|

Post by Oily Rag on Oct 15, 2018 21:25:19 GMT

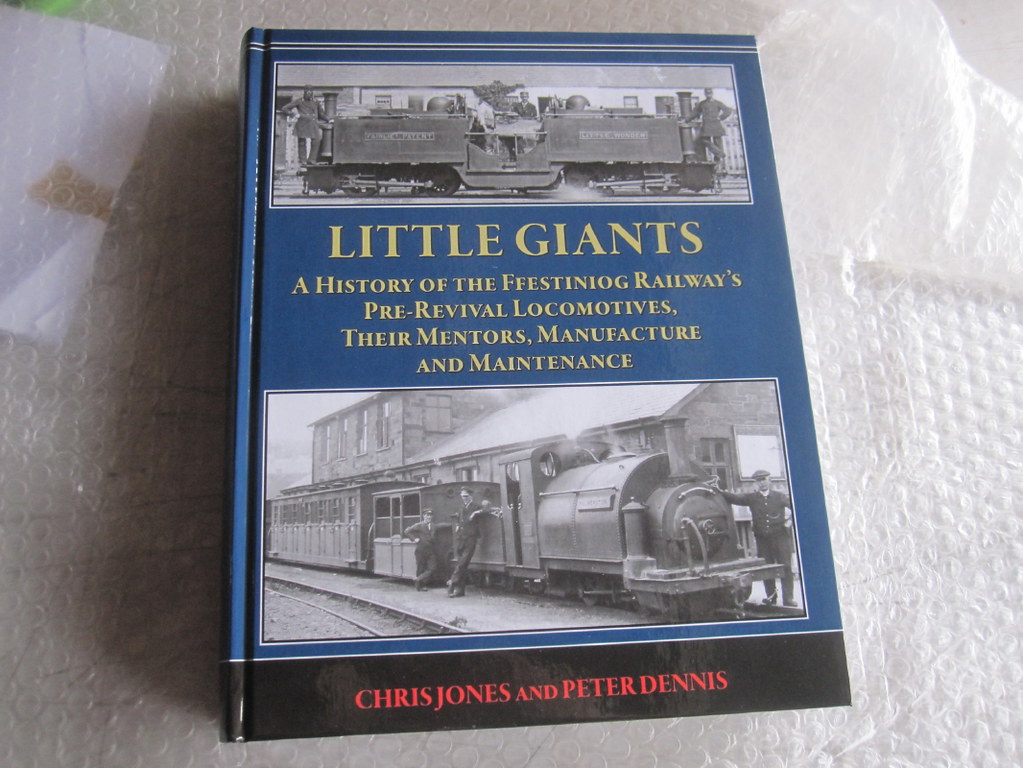

592 pages of goodness arrived yesterday. What a splendid book this is.

|

|

|

|

Post by ettingtonliam on Oct 16, 2018 1:42:06 GMT

I saw this in a bookshop earlier this week and was sorely tempted, but a cover price of £60 put me off a bit. Still, Christmas is coming----.

|

|

|

|

Post by Oily Rag on Oct 16, 2018 2:19:25 GMT

I saw this in a bookshop earlier this week and was sorely tempted, but a cover price of £60 put me off a bit. Still, Christmas is coming----.

Roll on Christmas for you say I :-) |

|

mbrown

Elder Statesman

Posts: 1,793

Member is Online

|

Post by mbrown on Oct 16, 2018 19:12:19 GMT

I got my copy of "Little Giants" last week - despite being a Talyllyn man who has only ridden on the Ffestiniog a fee times, I am finding it enthralling, just what a good engineering history should be. Last night I had to bring a pile of work home in the evening but I thought I'd allow myself "just 5 minutes" with the book before starting - you can guess the rest.... Managed to bluff my way through work today but it was a close thing!

If you like this kind of painstaking loco history, the 3 Volume work on the Corris and Talyllyn locos by Martin Fuller is similar in quality and fascination.

Malcolm

|

|

|

|

Post by Oily Rag on Oct 16, 2018 20:21:18 GMT

I got my copy of "Little Giants" last week - despite being a Talyllyn man who has only ridden on the Ffestiniog a fee times, I am finding it enthralling, just what a good engineering history should be. Last night I had to bring a pile of work home in the evening but I thought I'd allow myself "just 5 minutes" with the book before starting - you can guess the rest.... Managed to bluff my way through work today but it was a close thing! If you like this kind of painstaking loco history, the 3 Volume work on the Corris and Talyllyn locos by Martin Fuller is similar in quality and fascination. Malcolm

Our Queensland equivalent,from 1900 till the end.  |

|

|

|

Post by Oily Rag on Oct 17, 2018 2:37:46 GMT

Made a dash to see Mr Boiler Inspector before work. His comment after looking at my dry assembly of boiler parts,

“I will f_-k myself if that does not hold steam.” 😊

Gave me my boiler number and told me to cook it up and we will do the testing.

The onlookers liked my workmanship so I was quite chuffed (pun intended) It will be a while before I can cook it up as I am at Gympie (Mary Valley Rattler) the next three weekends as I am on crewing roster.

|

|

stevep

Elder Statesman

Posts: 1,073

|

Post by stevep on Oct 17, 2018 8:25:07 GMT

Well done Dazza. The boiler looks the dogs whatsits, and like your boiler inspector, I am sure it will be steam tight.

|

|

|

|

Post by Oily Rag on Nov 23, 2018 21:19:09 GMT

I have been away from the Red Room for some weeks. Big, long and hot weekends up at the Mary Valley Rattler.   I have my reciprocating steam ticket. YAY! It means I can spend time learning to be competent on the 12" to the foot scale choo choos. I have some space and a need to spend some time in the Red Room. Boiler is ready for cook up. I will approach that when I am more settled and have prepared some details. I am looking at making a start on boiler fittings, gauge glass bits seem like a good starting point. However I am seeking 9mm diameter hand wheels. Any one have a lead on a supplier ? |

|

|

|

Post by Oily Rag on Jul 1, 2019 22:47:58 GMT

|

|

|

|

Post by Oily Rag on Jul 10, 2019 10:42:31 GMT

|

|

|

|

Post by Oily Rag on Jul 10, 2019 12:23:11 GMT

Monday, light up 967 for test runs for the first time with carriages to Amamoor.

First movement was to shunt 974 out the way to get to the carriages.  First stop was at Monkland with 3 on the hook, to check bearing temperatures, all was sweet so onto Amamoor we go. I rode the cushions with Tanis (guard) on the way out. First stop was at Monkland with 3 on the hook, to check bearing temperatures, all was sweet so onto Amamoor we go. I rode the cushions with Tanis (guard) on the way out.

On the table at Amamoor. All is going fine. Setting back onto the carriages for the trip back. All is going sweet. Setting back onto the carriages for the trip back. All is going sweet. Roger was coming down with a cold and was not too sharp so he and I swapped and I rode in the cab and he went back to the van to keep Tanis company. I was to fire the second trip any how. Bernie the boiler inspector enjoyed a turn on the banjo. Roger was coming down with a cold and was not too sharp so he and I swapped and I rode in the cab and he went back to the van to keep Tanis company. I was to fire the second trip any how. Bernie the boiler inspector enjoyed a turn on the banjo.

Back at Gympie we have lunch and then back down to the shed to get the other 4 carriages to make up 7 on the hook. I fire the trip back to Amamoor. I give it my best go to get the three safeties to lift but like the others only got two to lift going up the Dawn bank. Going like a mad man was I. John has fitted three new Pop safeties and they clear all that can be boiled. We also did some measured out brake tests as well, which had the guard on the radio telling us that we had broken his seat belt

Back at the Amamoor table and Jerry the signing off Engineer has a smile. He got a drive and fire on the trip and is a past Rattler crew member. My wife worked (technical writer) with Jerry for two years a while back as he was the head engineer at Downer EDI in Marybough, making diesels and tilt trains etc. From the ground up, not imported kits ! But now those days are gone. Sigh! We had to stop on the both trips to open the dairy farm gates near Dagan. It is a 1/45 and on a curve and 967 gave a wee slip in the cow dung and then walked away with the 7. The motion and valves are spot on. The beat is even and ever so crisp. John gave it all a lot of attention and care from the ground up with the rebuild. We had to stop on the both trips to open the dairy farm gates near Dagan. It is a 1/45 and on a curve and 967 gave a wee slip in the cow dung and then walked away with the 7. The motion and valves are spot on. The beat is even and ever so crisp. John gave it all a lot of attention and care from the ground up with the rebuild.  The new boiler steams like a witch on speed. I had a wee adjustment due to the baffle being a bit more angled down to ensure I landed the toss at the front of the 8 foot long narrow grate. We have good Gunnadah coal so life is sweet. It was magic moment as all four in the cab know each other well and are good mates. Bernie, (Boiler inspector and the one who was my BA boiler tutor when I got my ticket), Jerry (engineer and signs off the compliance details), John (Maestro and project leader) and me the newbie firing and also I has some part and assistance with jobs on the rebuild. I got all of their attention during the run back and said "fellas this is magic, making memories and this is ever so special" it was super special. I was into my economical firing routine, getting used to the slower feeding injector which I quite like. I got the fire and water level right for the run off six mile bridge up the grade to the parallel run next to the main line. The run into Monkland I get my rounds in and alight and a few uphill pulls gets it all nice bright and a few squirts to the level right for the drop down to Deep Creek Bridge. On the way down I load the grate, using some big lumps that I have saved for under the door and throwing a good lot at the front 8 feet away. A few down the middle with the tap on the bottom fire hole ring to spray it about. I hear the sounds that tells me are on the bridge. Water is a 1/3 in the glass on the level run over the bridge. A good plume of smoke is trailing us and I have the door open half to burn the volatiles off. Jerry cracks it on a bit as we roll onto the bank, the first 800m are not steep, good to get the loaded grate going but it then kicks up and we are then into 1/50 to 1/40. I have the needle on 165 and as it gets close to 170 I kick my injector on and off to keep the pop valves from lifting at 170 and to keep the water topped up. They seat again at 160 after a ten pound drop, so just for my satisfaction I keep it at 165 t0 167 all the way up and the fire is stinking hot after a km. I don't touch the fire at all on the way up to Gympie if I get it right. I get it all stinking hot and at the same time bring the water into balance with it and then bomb the grate after Monkland. If the timing is right it goes off like a bomb and by crikey the run up is fun. Many with much more hours than me fire 3-4 times on the climb, but I very rarely do. The new boiler steams like a witch on speed. I had a wee adjustment due to the baffle being a bit more angled down to ensure I landed the toss at the front of the 8 foot long narrow grate. We have good Gunnadah coal so life is sweet. It was magic moment as all four in the cab know each other well and are good mates. Bernie, (Boiler inspector and the one who was my BA boiler tutor when I got my ticket), Jerry (engineer and signs off the compliance details), John (Maestro and project leader) and me the newbie firing and also I has some part and assistance with jobs on the rebuild. I got all of their attention during the run back and said "fellas this is magic, making memories and this is ever so special" it was super special. I was into my economical firing routine, getting used to the slower feeding injector which I quite like. I got the fire and water level right for the run off six mile bridge up the grade to the parallel run next to the main line. The run into Monkland I get my rounds in and alight and a few uphill pulls gets it all nice bright and a few squirts to the level right for the drop down to Deep Creek Bridge. On the way down I load the grate, using some big lumps that I have saved for under the door and throwing a good lot at the front 8 feet away. A few down the middle with the tap on the bottom fire hole ring to spray it about. I hear the sounds that tells me are on the bridge. Water is a 1/3 in the glass on the level run over the bridge. A good plume of smoke is trailing us and I have the door open half to burn the volatiles off. Jerry cracks it on a bit as we roll onto the bank, the first 800m are not steep, good to get the loaded grate going but it then kicks up and we are then into 1/50 to 1/40. I have the needle on 165 and as it gets close to 170 I kick my injector on and off to keep the pop valves from lifting at 170 and to keep the water topped up. They seat again at 160 after a ten pound drop, so just for my satisfaction I keep it at 165 t0 167 all the way up and the fire is stinking hot after a km. I don't touch the fire at all on the way up to Gympie if I get it right. I get it all stinking hot and at the same time bring the water into balance with it and then bomb the grate after Monkland. If the timing is right it goes off like a bomb and by crikey the run up is fun. Many with much more hours than me fire 3-4 times on the climb, but I very rarely do.

The light is fading and the scene and noise is magic.  My tea can is empty and there is only a few minutes to go. My tea can is empty and there is only a few minutes to go.

Under the white foot bridge with 400 meters to go and I get the injector going as the summit is actually 50 meters into the platform and one wants the crown covered for the braking stop as well.

We pull up with smiles all over as the loco is running fine. During the pause at the platform I am pleased as I nailed the trip back, only one pop of the safeties and that was when we had to stop to open the dairy crossing and close it behind us. Just a few things for John to attend to on the loco this week but it looks all good for service next month. We shunt drop the fire and then John and I get our skates on to shower and get to the Pub before the kitchen closes at 8.00 pm. We are both farnarkled and I especially so after also lighting up at 5.00am and firing one trip, with the brake tests and the accumulation test as well, after three long days of steam, so I stay another night in the donger again because driving home would be tempting fate. I was tired and happy and so I have a pint of Guinness as John has a pint of FourX gold. I am truly living the dream.

This weekend, the plan is cook up my boiler which has been waiting patiently for 8 months.

|

|

|

|

Post by Oily Rag on Jul 10, 2019 20:41:20 GMT

I forgot to mention, I worked Thursday morning, drove the 2 hours to Gympie, loaded the timber trolley (Empty = sigh) and two grates for Friday. I also fired the Saturday AM service and drove the PM service. Sunday was Guard duty with two trainees in tow. So it w 4.5 days of enjoyable toil at the Rattler. A few more pics from Monday. A few more pics from Monday.

Tanis (guard) is about to hook the air bag up to drive the table.

|

|

|

|

Post by Oily Rag on Jul 14, 2019 21:39:50 GMT

As I worked in the bike room prepping my boiler parts, MAM was doing some painting, she calls it"Bary T Wedgie" (Wedge tail portrait that gets the smiling caricature look) She is intending to exhibit it at an amateur show.

Super header header mount cooked to the tube plate with 45% Harris.

Filing clearance flows into the copper rivets used as pins. A bit like bike frame making in the good old days.

Ready to cook up. The prep took a lot of time. I have never brazed this amount of copper, even though it is not a big boiler I know copper conducts heat differently than steel and I have brazed steel for 40 years, so I was not sure what I was expecting. I had planned the process and was ready to go. MAM was playing with oils and pottery clay as I lit the torch. Ready to cook up. The prep took a lot of time. I have never brazed this amount of copper, even though it is not a big boiler I know copper conducts heat differently than steel and I have brazed steel for 40 years, so I was not sure what I was expecting. I had planned the process and was ready to go. MAM was playing with oils and pottery clay as I lit the torch. It went OK, the good heat induction tricked me, things were flowing in places I was not yet paying attention to. If I was to do a couple of more I reckon I will hit my marks better. It went OK, the good heat induction tricked me, things were flowing in places I was not yet paying attention to. If I was to do a couple of more I reckon I will hit my marks better.

I used Harris 56 and Cycle Designs flux which is the best brew I have used. I have used many over the 40 years in my daily work, the main stream brands are not as good as this. I used the air sucker to soak it a bit to save Oxy and then my LP rose bud gave all the heat I ever needed. I could have used the small rosebud.   Did my fillet witch wand thing with the bushes from bike making habits, but then I realised that might not be a good with with the fit of the cladding and so might requires some filing to remove. Whoops. Did my fillet witch wand thing with the bushes from bike making habits, but then I realised that might not be a good with with the fit of the cladding and so might requires some filing to remove. Whoops.  One seam, the inner to the throat plate looked fine on one side, but I was not positive about the flow under it and on the inside, so I cooked it up again and and made sure. All it would have taken is 5-8 seconds of playing the flame in the right spot to enure the flow was confirmed when the cook up was in full swing but I missed it, next time eh. I took no prisoners, I poured the silver in. Checked all the flows, all seems OK. One seam, the inner to the throat plate looked fine on one side, but I was not positive about the flow under it and on the inside, so I cooked it up again and and made sure. All it would have taken is 5-8 seconds of playing the flame in the right spot to enure the flow was confirmed when the cook up was in full swing but I missed it, next time eh. I took no prisoners, I poured the silver in. Checked all the flows, all seems OK.

To the hot water to remove flux and then to the pickle.

|

|

|

|

Post by David on Jul 14, 2019 22:07:40 GMT

Looks great! That shot into the water space shows no distortion or movement of the parts. Can't wait to see it cleaned up. Also really glad to see some progress on the small stuff.

How do you form such nice fillets - the photos in the stainless thread were really impressive. And where do you get your silver solder and special flux? I can get silver solder from the local BOC but always interested in alternatives.

|

|

|

|

Post by Oily Rag on Jul 15, 2019 22:17:00 GMT

Looks great! That shot into the water space shows no distortion or movement of the parts. Can't wait to see it cleaned up. Also really glad to see some progress on the small stuff. How do you form such nice fillets - the photos in the stainless thread were really impressive. And where do you get your silver solder and special flux? I can get silver solder from the local BOC but always interested in alternatives.  ) and also some work on the rebuild of #967, but I enjoyed my time last Sunday in the Red Room. ) and also some work on the rebuild of #967, but I enjoyed my time last Sunday in the Red Room.

I used copper rivets as pins to hold some parts in place.

The fillets is using gravity and using the torch around the bush to get a even temp while feeding in to even it all to flow to a fillet after wetting it through first. I have used a brazing torch for many decades with my daily work, so I may have a wee jump ahead. You do have to orientate the job to use gravity to form a fillet in silver. There is also fillet brazing with the heat and dab flow melt into the joint with a wet out, this is used with brass fillers with bikes. There is also the fillet brazing with brass that gives the appearance of TIG welded aluminum stack of coins but I am not convinced that is the best way.

Pic is 0.70mm chainstay bridge brazed to the 0.70mm chainstay on a bike frame. The cut out is actually brass brazed and the vent hole is sealed with 2.00mm mild steel nail and a dab of silver before it cools.

My biggest adjustment is the heat flow characteristics of the heat flow with copper and I have never cooked up so much copper in my life. If I had a few of these little boilers to braze up in a row I would be more relaxed and satisfied with a neater result. My work is about brazing neatly to save clean up time and still maintain integrity.

The silver is Harris 56 Cad free. I get it by the KG from my Harris distributor in Brisbane. The "Cycle Designs Stainless Lite flux" I get from Keith Marshall at Kumo Cycles. Ph 04158 90080 He is near Canberra. Tell him Dazza sent you. |

|

|

|

Post by Roger on Jul 16, 2019 8:10:14 GMT

Lovely work Dazza, absolutely first class. I like the little holding down arrangement on the thin shell.

|

|

|

|

Post by Oily Rag on Jul 16, 2019 21:18:21 GMT

Lovely work Dazza, absolutely first class. I like the little holding down arrangement on the thin shell.

My bike work bench becomes a flurry of files and paper as I rattle through the working day. The Red Room is never like this.  |

|

|

|

Post by Oily Rag on Jul 25, 2019 21:02:44 GMT

The weekend plan is to cook the back head in place. All seems to be structurally as it should be and square. I poured a lot of silver into this assemblage of copper, I was not all that pleased with the neatness, but that is an adjustment to working with copper rather than steel.

|

|

|

|

Post by Oily Rag on Jul 25, 2019 21:08:24 GMT

Lovely winter mornings at Gympie, over night down to Zero, foggy mornings, then lovely clear sunny and warm days, which beats the 40 + degree summer days with over 50 in the cab.

Last weekend, a couple of light-ups, driving and firing and Sunday of guarding. Living the dream.

|

|