|

|

Post by steamer5 on Nov 6, 2019 8:38:47 GMT

Hi Daz,

Quote...” I am yet to make the dummy rivets, in stainless.”

Hmmmm seemed to have read this before......oh yeah the previous post......we are still waiting to see how you do it!

Oh the door looks terrific!

Cheers Kerrin

|

|

|

|

Post by Oily Rag on Nov 7, 2019 21:05:03 GMT

I got a cheap little Rotary table some time ago and never used it, till last night when it was just the ticket to get the 24.55mm radius on the upper part of the petticoat.

|

|

|

|

Post by Oily Rag on Nov 11, 2019 20:40:59 GMT

1" Brass, a wee spin in the Myford. The Turnado turning system put the radius on the Chimney base piece. Then one hour with the files and grits while ABC jazz was on the radio has one side blended in. Then one hour with the files and grits while ABC jazz was on the radio has one side blended in.

|

|

|

|

Post by David on Nov 11, 2019 21:59:57 GMT

How did you scribe the line of the boiler on the bottom? It looks too neat to be freehand.

There was an interesting article in Model Railway Journal by Paul Bernstein about turning chimney and dome bases in small scales that would probably work for your loco. Something like an endmill or stone in the lathe chuck and the work mounted on a sprung arbor in the toolpost so as you rotated the arbor the boiler profile cutout in the base of the work moved against the 'arbor tool' it was mounted on presenting the correct part of the work to the cutting tool in the chuck. I'm sure I tried it for an O scale chimney or dome and it worked. It's difficult to describe.

|

|

stevep

Elder Statesman

Posts: 1,073

|

Post by stevep on Nov 12, 2019 9:39:38 GMT

How did you scribe the line of the boiler on the bottom? It looks too neat to be freehand. There was an interesting article in Model Railway Journal by Paul Bernstein about turning chimney and dome bases in small scales that would probably work for your loco. Something like an endmill or stone in the lathe chuck and the work mounted on a sprung arbor in the toolpost so as you rotated the arbor the boiler profile cutout in the base of the work moved against the 'arbor tool' it was mounted on presenting the correct part of the work to the cutting tool in the chuck. I'm sure I tried it for an O scale chimney or dome and it worked. It's difficult to describe. David, That sounds like the system described by Sir Ron East (or was it West) in ME some years ago. I used it for my 3 1/2" Rob Roy and my 5" Stanier, so not just for the small scales. |

|

|

|

Post by Oily Rag on Nov 12, 2019 20:17:06 GMT

How did you scribe the line of the boiler on the bottom? It looks too neat to be freehand. There was an interesting article in Model Railway Journal by Paul Bernstein about turning chimney and dome bases in small scales that would probably work for your loco. Something like an endmill or stone in the lathe chuck and the work mounted on a sprung arbor in the toolpost so as you rotated the arbor the boiler profile cutout in the base of the work moved against the 'arbor tool' it was mounted on presenting the correct part of the work to the cutting tool in the chuck. I'm sure I tried it for an O scale chimney or dome and it worked. It's difficult to describe.

The bottom was fly cut using a 50 mm boring head.

I then used the Turnado free hand turning system to put the radius in . I then used my vernier scriber to put 0.80mm line from the edge and then a new 6" half round file and wooden dowels and grits, done to 1000 to finish off the changing radius bends. If one looks at many of the full size castings you can see how rough they can be and the shapes are not perfect blends. |

|

|

|

Post by Oily Rag on Nov 12, 2019 20:46:17 GMT

|

|

|

|

Post by Oily Rag on Nov 13, 2019 22:53:03 GMT

Simple stuff last night while the east coast of Australia burns or at least is smouldering. Blast pipe.

|

|

|

|

Post by Oily Rag on Nov 17, 2019 22:44:52 GMT

|

|

|

|

Post by Oily Rag on Nov 17, 2019 22:48:20 GMT

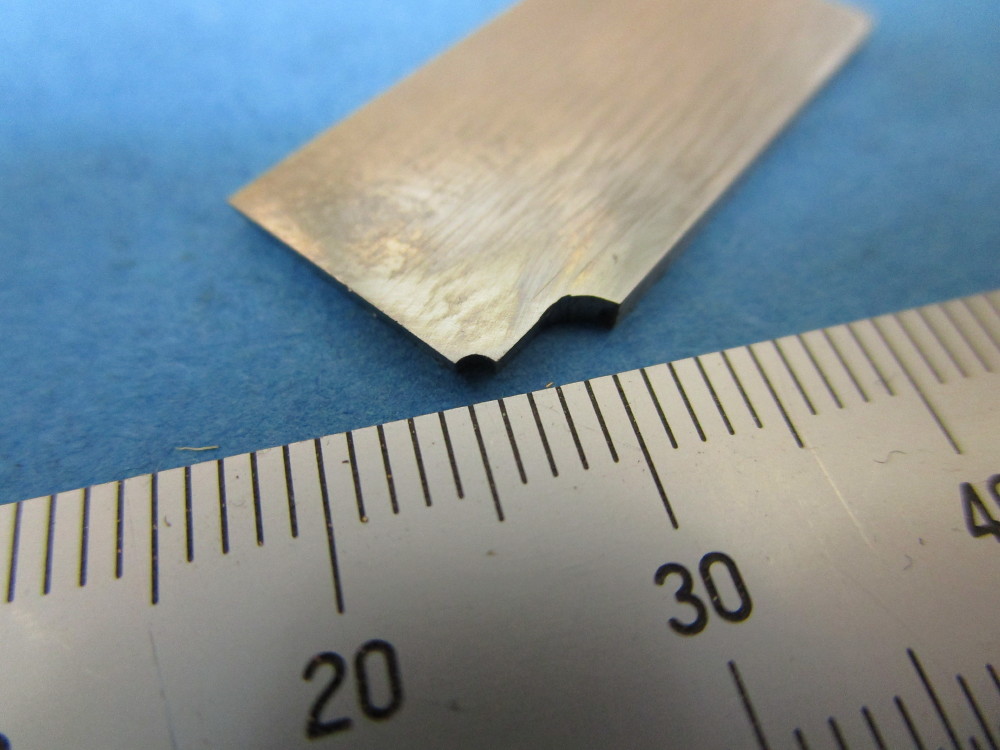

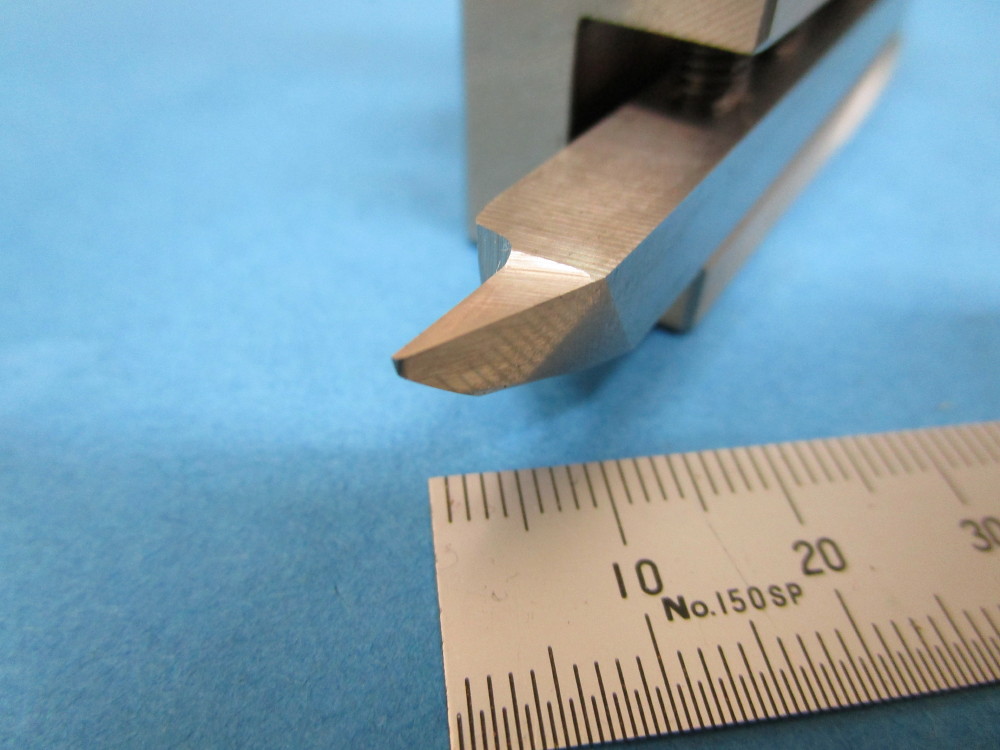

Making tools to make the 1.60mm diameter rivets for the smoke door hinges.

I will not be surprised if this does not work, but I have a few approaches to try with this method.

|

|

|

|

Post by 92220 on Nov 18, 2019 9:56:26 GMT

Hi Dazza.

It's looking good! I'm curious though. Why are you going to the trouble of making the 1.6mm rivets rather than buying them?

Bob.

|

|

|

|

Post by Oily Rag on Nov 18, 2019 20:48:27 GMT

Hi Dazza. It's looking good! I'm curious though. Why are you going to the trouble of making the 1.6mm rivets rather than buying them? Bob.

I could not source stainless steel rivets for the stainless steel hinges so they look like this  |

|

|

|

Post by Oily Rag on Nov 18, 2019 20:53:43 GMT

Last night was proof of concept. I was pleased it worked. I made a second one to ensure it was not a fluke. I will make the rest of them soon and alter the settings to get a flatter dome.

|

|

|

|

Post by 92220 on Nov 19, 2019 13:01:25 GMT

Hi Dazza.

I hadn't realised you were aiming for stainless rivets to go with stainless hinges. Now I can see the logic. Looks like the rivets have turned out very well too.

Bob.

|

|

|

|

Post by Oily Rag on Nov 19, 2019 20:05:56 GMT

Squeeze the tweezers too hard and "Ping" , two were teleported to another time and dimension last night. One was ruined, too tight a fit. But the last one was made in 15 mins, I am getting across the process and feel. 5 to go. I use a sharp centre pop to make them a press fit. The hinges will be silver brazed into the door. It is fun. Not some thing I want to do every week and I will be sated when these are done.

|

|

|

|

Post by Oily Rag on Nov 21, 2019 20:38:28 GMT

The little blighters were completed while listening to the Aust/Pakistan first test at the Gabba here in Brisbane. Cook up is next but later as this weekend I am off to the Rattler for DEL driving time as the fire ban is on. It is very grim here.

|

|

|

|

Post by steamer5 on Nov 22, 2019 8:35:29 GMT

Hi Daz,

Those rivets look the part!

Could’ve sent you some rain earlier in the week but you guys keep sending the wind this way! Hope things improve over your way soon!

Cheers Kerrin

|

|

|

|

Post by David on Nov 23, 2019 10:54:59 GMT

The loco is really looking the business now. Really clever idea with the hinges too only having to form the top side of them.

|

|

|

|

Post by Oily Rag on Nov 24, 2019 22:20:47 GMT

The loco is really looking the business now. Really clever idea with the hinges too only having to form the top side of them. |

|

|

|

Post by David on Nov 24, 2019 22:26:05 GMT

Ah, I hadn't seen the others.

|

|