|

|

Post by Oily Rag on Dec 1, 2019 20:03:03 GMT

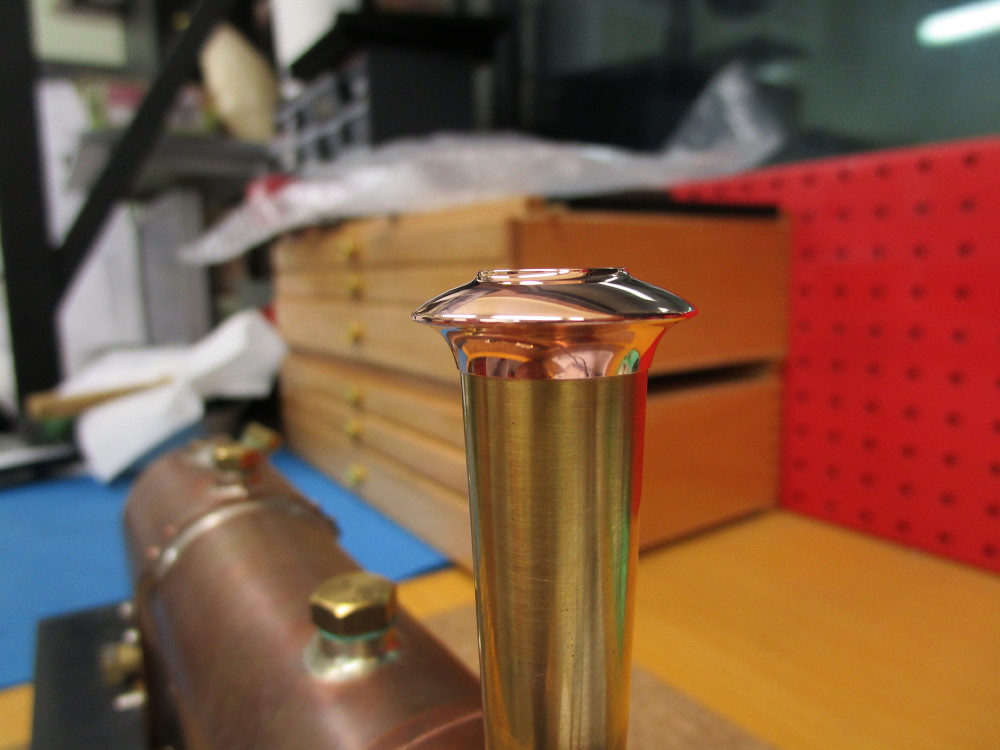

One inch copper via ebay meets lathe and the Turnado. The workshop crew have a yarn while the foredog contemplates the next operation. The workshop crew have a yarn while the foredog contemplates the next operation. A wee polish A wee polish "Come and see" Often echoes down the corridors of the works. "Come and see" Often echoes down the corridors of the works.

With 0.005mm interference fit on it goes  The inspiration. The inspiration. That was a whole Sunday for this little fella but the crew are well pleased, and for those inclined, it is free lance, simply inspired by the GWR. That was a whole Sunday for this little fella but the crew are well pleased, and for those inclined, it is free lance, simply inspired by the GWR.

|

|

|

|

Post by simplyloco on Dec 1, 2019 20:13:22 GMT

One inch copper via ebay meets lathe and the Turnado.SNIP Absolutely delightful! John |

|

|

|

Post by David on Dec 1, 2019 22:23:50 GMT

WOW! That's really nice.

|

|

|

|

Post by steamer5 on Dec 2, 2019 6:41:54 GMT

Hi Daz,

Given the fires over you way I would of thought making something that shinny would have every Magpie in the district flocking to your place, NICE!

Cheers Kerrin

|

|

|

|

Post by Oily Rag on Jan 20, 2020 21:15:45 GMT

When did I put the 3mm spanner ?  I had it 5 minutes ago, where is the &*#%@!*&@$$!!!* thing? I had it 5 minutes ago, where is the &*#%@!*&@$$!!!* thing?

30 mins of tiding up the bench, check the floor, put a few tools away.

Still no show.

OH well, move on and get the junk spanners out.

Then 3 hours later WTF! " I suppose your think you a clever little spanner eh! " I suppose your think you a clever little spanner eh!

If you did not cost so much I would give you a decent flogging with 20 oz ball pean hammer!"

|

|

|

|

Post by Oily Rag on Jan 20, 2020 21:21:11 GMT

Looking after Mum, getting crook a few times, no work on the loco. However the first stage of the signal installation on the Potters Orchid garden railway is well underway. They are nearly ready for installation. These will be only fitted for special steam up days. The final landscaping of the back yard and the railway can begin and the goal is to complete this by the end of the year with major earth works and pathway construction taking place in the cooler weather. Also I will back on the Rota at the Rattler next month. I need some full size loco time.

|

|

mbrown

Elder Statesman

Posts: 1,793

|

Post by mbrown on Jan 20, 2020 22:15:00 GMT

" I suppose your think you a clever little spanner eh!

If you did not cost so much I would give you a decent flogging with 20 oz ball pean hammer!"

Well, it took me several minutes to spot th3e little so-and-so - as good as a "Where's Wally" book!

Malcolm

[/quote]

|

|

|

|

Post by Oily Rag on Jan 21, 2020 20:22:53 GMT

" I suppose your think you a clever little spanner eh! If you did not cost so much I would give you a decent flogging with 20 oz ball pean hammer!" Well, it took me several minutes to spot th3e little so-and-so - as good as a "Where's Wally" book! Malcolm [/quote] I must have put the little blighter down on the saw frame as I worked and I managed to put the saw frame on the hook without dislodging it as I tided up in my search for it. |

|

|

|

Post by Oily Rag on Feb 23, 2020 21:01:52 GMT

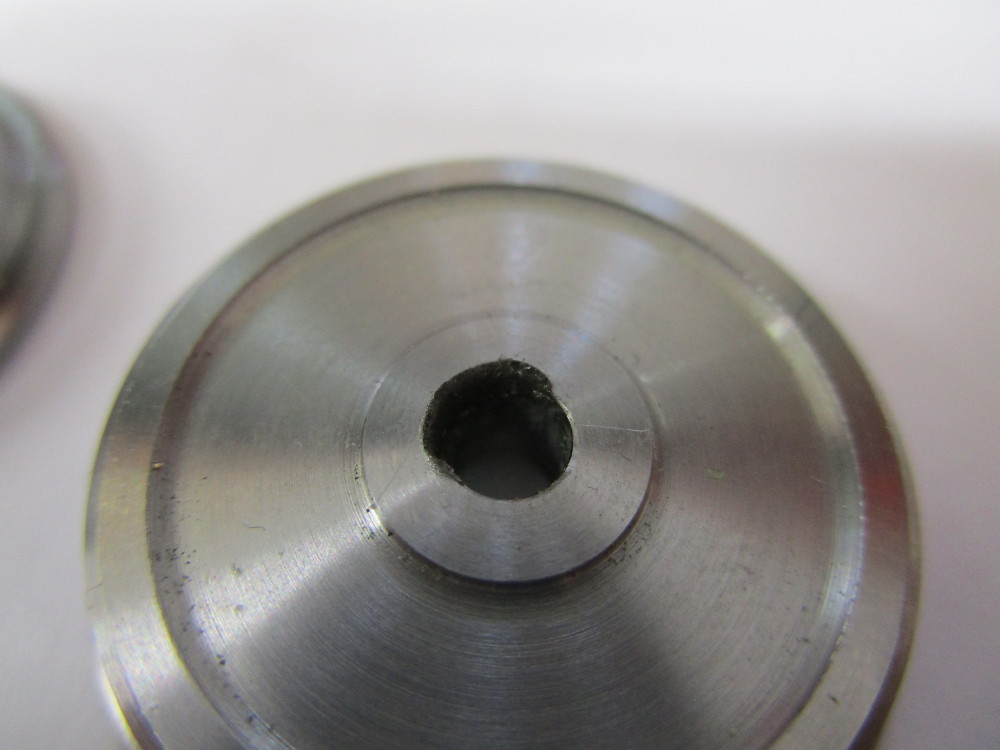

Same mandrel as used for the driver wheels. Clocked in the P & B floating 3 jaw to .005mm and then whurrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrr   Remove the feather of a burr Remove the feather of a burr

The Llewellyn Loco Works management are pleased with Sunday's out put from the Red Room workshop. The Llewellyn Loco Works management are pleased with Sunday's out put from the Red Room workshop.

|

|

|

|

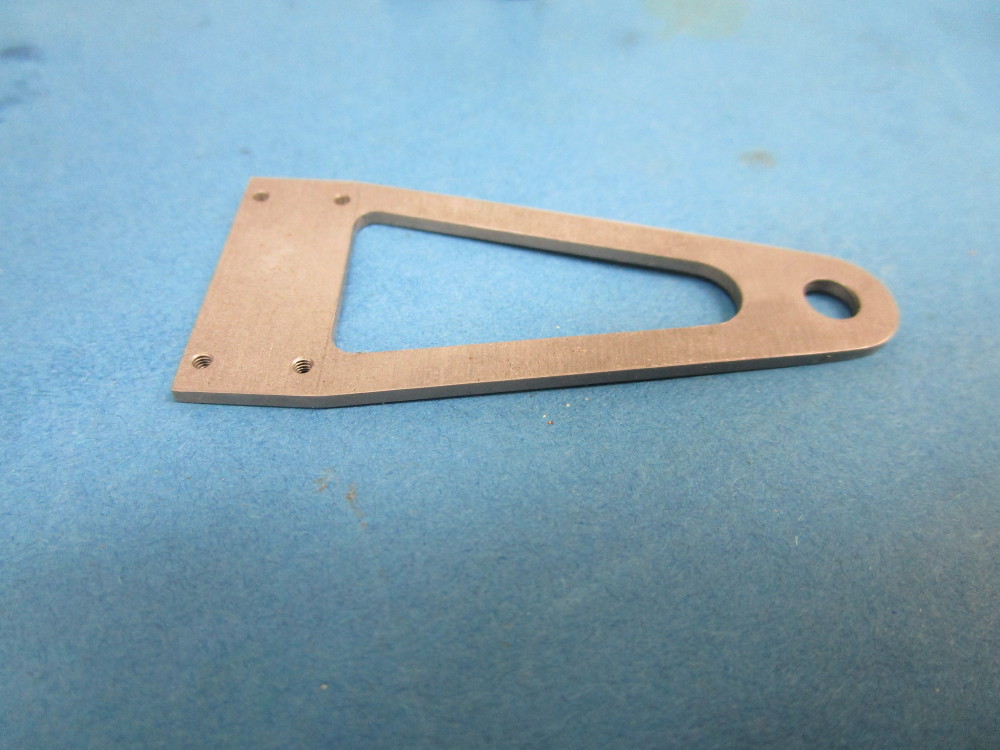

Post by Oily Rag on Feb 24, 2020 20:38:29 GMT

M3 threads for gauge widening went in last night, with a wee counter bore to be neat.

|

|

|

|

Post by Oily Rag on Feb 29, 2020 21:41:34 GMT

Pony Truck Frame completed. While the just down the corridor, Senior management was dabbling with her paint brushes.

|

|

|

|

Post by Oily Rag on Feb 29, 2020 21:43:04 GMT

The collection of filing buttons is growing.

|

|

|

|

Post by Oily Rag on Feb 29, 2020 21:46:55 GMT

Inspired by her oil on board morning, it was then to the Red Room and up stairs to the kitchen to bake off her smoke box. I am sure this was in MAM's thoughts when she chose the oven.

|

|

|

|

Post by Oily Rag on Feb 29, 2020 21:50:21 GMT

Meanwhile the staff at the Llewellyn Loco works were working of the frame stretcher that the truck attaches to and the grate support release pin will be located.

"Shaun, I see management have already got the red editing pen out before we even start cutting, I hope they got it right."

|

|

|

|

Post by Oily Rag on Mar 2, 2020 20:26:45 GMT

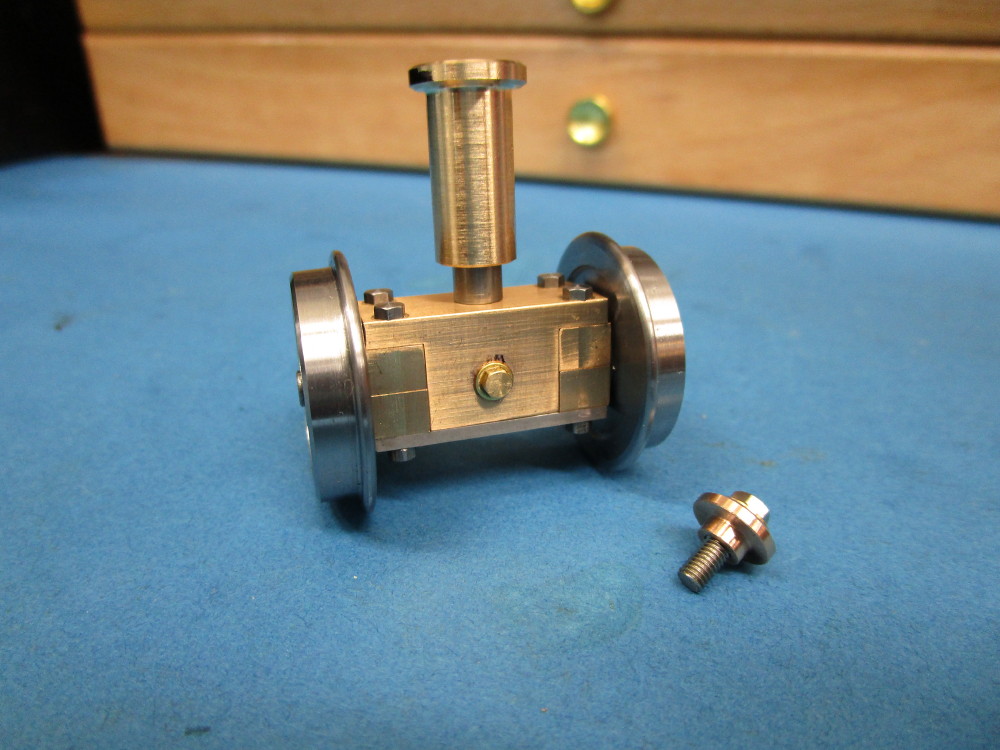

Drill, 4.70mm, ream 3/16" , polish the 3/16" silver steel axle, spin the axle in the mill while holding the truck. Bingo, sooth as ................................. Management are pleased.

|

|

|

|

Post by Oily Rag on Mar 10, 2020 3:59:07 GMT

|

|

|

|

Post by Oily Rag on Mar 15, 2020 21:29:53 GMT

Yesterday arvo, senior management felt they needed some time in the Red Room, despite feeling like they had Covid 18.5 3/16" silver steel axle ends were turned, then the wheels pressed on. Did not go to plan. SIGH! One edge broke out.  So it was back to the lathe and a new wheel and axle and Loctite and all went well. So it was back to the lathe and a new wheel and axle and Loctite and all went well.

Management is dim, in hindsight, why did they not make it 0.01mm inference and heat the wheel to slip it on. Why ? Simply dim!

|

|

|

|

Post by Oily Rag on Mar 15, 2020 21:35:31 GMT

Pony truck is done. The 10BA brass screw in the back of the Cannon type axle box is for injecting oil. Split Bronze bearing. Runs as smooth as silk. Later when the loco is complete I will measure axle loads and fiddle the spring to get the driver loads even.

|

|

|

|

Post by Oily Rag on Mar 24, 2020 22:41:31 GMT

While I shake off the plague, (not the #19) I have devoted a few hours each day to the Doctrader simulator and loaded the Queensland railway C17 class valve motion into it, working off the QR drawings, cross checked McKenzie’s 5” gauge drawings and my 3D model for the 5” gauge build (to be my Magnum Opus. All seems pretty good. I only got one 0.50mm error in X for the location of the expansion link trunnion centres, I am yet to check that on my 3D drawings if it is my mistake or the McKenzie drawings. McKenzie copied the QR directly. Shame the rest of his drawings have little detail. Any how it is all the valve events and diagrams. It all matches the tables in John Knowles big Red Book on page 142 and other pages. Doctrader C17 valve gear model seems to be on the mark, it matches within one percent what Knowles has in his book with tables in regards to compression and openings etc. I checked my 3D drawings I did 7-8 years ago (many evenings) and all looks good so far but for the small error in location of the link trunnion centre. YAY! I will check this today. I am not returning to Mother's house to the dusty mess till my cough and sinuses are clear for two full days. (On MAM's orders!) Waiting for the bespoke axle box castings to arrive from NZ so I can make a start on the tender of the little loco. Need to crack on with that as I want to start on the Magnum Opus. Pics below with all the unnecessary parts turned off, transparency of the cylinder block turned on. Crikey, I forgot how much work I put into the 3D model, the wheel centres are diagrammatic as there was no need to go into detail with curves and forms unless I was making a casting pattern (3D print). That may still occur as the 5" wheel castings do not look right, but I am yet to have one in my hand to inspect them properly.The valve gear all moves correctly. I can move the reverser etc and all rotates.

|

|

|

|

Post by TheMadNata on Mar 25, 2020 1:50:49 GMT

What number C17 did you model? If I remember from our chats it’s a really early number and I’ve spot a number of detail errors.

|

|