|

|

Post by suctionhose on Sept 2, 2016 13:34:21 GMT

At least on two recent threads I have read about 1"scale steam pumps - Westinghouse style - being unreliable.

I'm quite sure there are many unreliable pumps about but that does not mean they are inherently unreliable. There are 3 Australian manufacturers and one in New Zealand that I know of. More in USA I would say.

I have personal knowledge of two of the Australian Pumps purchased for my engines after a time / cost analysis. Both worked without fault for years.

The Westinghouse type made by W Sandberg is a working replica with trip rod, pilot valve and shuttle driven main valve exactly as original with one modification. On a full size Westinghouse the Main Valve is moved by a shuttle having a large piston on one end and a small piston on other. This is because the return movement of the valve is powered by exhaust steam - hence the larger piston.

(And the cause of a worn pump stalling, prompting somebody to whack the valve box with a hammer....)

As the shuttle valve is only about 1/4" dia in 5" gauge, the exhaust steam is insufficient for this purpose. The main variation in model form is to move the shuttle with live steam in BOTH directions. This requires some alterations to ports (which are tiny #60 or less) but the result is extremely reliable even at 10 strokes a minute.

The other important addition to the installation is a bleed valve in the delivery to help the pump displace air from the pipes until the suction is drawing solid water and there's no cushioning air bubble captured between pump and boiler check valve. Once fully "hydraulic" the water has to go somewhere!

Steam should be hot so run the pipe through a hollow stay or even superheat / dry it before entering pump. Lubrication is very light.

I always left my pump wet and primed and never had a problem even after long periods of no use.

The only time I did have to repair it was when the trip rod got bent through an error of my own doing which caused the pump to overspeed - on air - (hundreds of strokes a minute unnoticed then it just stopped...). Repair was a very delicate operation highlighting the delicate nature of making the thing in the first place. Not my work as I already confessed.

The other pump was externally a model of a cross compound compressor. However, internally it was a single cylinder, double acting pump with an oversized shuttle and lubricator housed in one half of the dual pump arrangement.

It too, was a perfect performer.

The third design - the Harris - from memory departed from the Westinghouse design in a minor way having a different, possibly easier-to-make valve system. I have no direct experience of the Harris although they were popular in the home state where they were made.

|

|

jma1009

Elder Statesman

Posts: 5,925

|

Post by jma1009 on Sept 2, 2016 19:21:20 GMT

Hi Ross,

Thank you for that very useful and informative posting.

I would be very interested to see the drawings of the pumps to which you refer.

I have never made one, but it is something I have been fascinated by. I have driven a few locos with them fitted including the Walton tank of the SMLS referred to by Adam Cro.

Being an ex-Isle of Wight 'overner' now an immigrant in South Wales, most of my life was spent in close proximity to fullsize locos on the Isle of Wight with Westinghouse pumps. Although my 5"g Stepney loco ceased to have a Westinghouse pump in the 1930s, I would still like to try and make a working example in miniature. Jim Scott very kindly sent me a set of the smallest Southworth pump drawings. I think I have most designs for pumps published in ME though I am missing apparently a single cylinder LBSC type from the 1930s.

I also have most of the Bill Van Brocklin stuff from the USA. The American guys are quite keen on Westinghouse pumps though in 7.25"g it is a much easier proposition!

Cheers,

Julian

|

|

mbrown

Elder Statesman

Posts: 1,798

|

Post by mbrown on Sept 2, 2016 20:15:21 GMT

Dear Ross,

May I second Julian's message - I too find steam pumps fascinating and hope one day to make one in miniature. I just need to choose a design of loco to attach it to....

We have them now on the TR. Ours are like the early design of Westinghouse pump with a small piston valve working vertically above the steam cylinder, actuated by the usual trip rod, and this then feeds steam to a shuttle piston which is in turn connected directly to a piston valve operating vertically alongside the main cylinder. They are pretty reliable provided they get enough oil (I estimate that they use more in a trip than the mechanical lubricators for the loco cylinders themselves...) but sometimes stick and have to be turned off to allow the piston valve to fall and then be re-started. There is a big debate about whether the piston valve heads ought to be of slightly different sizes so that there is a bias to one end of the travel so the valve can't stick in mid-position, but as far as I know they haven't tried the modification yet.

I would love to see any drawings for model pumps that you may come across that are both realistic and capable of being built by an average model engineer. I assume you are familiar with Don Young's drawings, borrowing the Van Brocklin design, which he published in LLAS as part of his 7.25" Terrier design.

Malcolm

|

|

jma1009

Elder Statesman

Posts: 5,925

|

Post by jma1009 on Sept 2, 2016 20:40:15 GMT

Hi Malcolm,

The Don Young version of the Van Brocklin design for Don's 7.25"g Newport Terrier I have studied very closely plus have all the construction details from LLAS.

I havent seen one working - yet!

Don's own attempt published in 1966 in ME for his 5"g Fishbourne wouldnt work.

There is a very good series of articles in ME I think in the 1960s on fullsize pumps. I think it was one called the Richardson that caught my attention. If I have the name correct it was very clever design that would make a very good miniature type.

On the Westinghouse type in fullsize the shuttle valve often gets stuck in the wrong position, requiring a judicious clout with a lead hammer on the top casting to get it to free itself. If you scale down the Westinghouse type it gets very very fine in 5"g.

If you dont mind the outside rocker arms the LBSC type is well proven and works well.

I had a good look at the Roy Amesbury design for his 5"g Caledonian 2-4-0 but it was neither Westinghouse or anything else, and sounds a bit like Ross's description.

Gerry Tull's award winning 5"g IW O2 Totland had a scale Westinghouse pump fitted but never saw it running, despite me prompting Gerry when the loco was running round the IWMES track.

Really this ought to linked to Joan's recent thread.

Cheers,

Julian

|

|

|

|

Post by 4fbuilder on Sept 2, 2016 23:00:49 GMT

Good evening Julian,

What an interesting thread. The SMLS Halton tank is fitted with an Austin Walton twin cylinder pump. Many years ago I decided I needed to replace the dummy pump on my terrier with a working model. Armed with a note pad and a rule it was off to the Bluebell to measure one up, so the task commenced, lots of sketches, references to probably everything that had been described previously and I subsequently managed to produce a working scale sized pump, the main difference being the main valve was hidden in at the rear of the steam cylinder and I used a piston valve for the trip valve, the main thing with the trip valve is having sufficent resistance on the trip rod to ensure the dwell on the trip rod, that I managed by using a tiny O ring in the steam cylinder top cover. The water side was easy in comparison. I used .375" bore on the steam side and .25" bore for the water pump cylinder, we're not talking those large Van Brocklin types but for 5" gauge. The pump would work first class provided there wasn't any condense carry over in the steam supply, that would stop it. I took my pride and joy to my great friend the late Lionel Woodhead who had almost finished a Brighton B4, and thats where it resides today, I never did get to fit it to the terrier! The only other person who followed a similar route was Fred Lownes, I think he built at least three, one of which was fitted to John Seymour's 5" WD 2-10-0.

The larger "Westinghouse" types for 7.25" gauge and larger probably by Van Brocklin etc and the Don Young lucky seven pump were based on the design by Moodie E Braun, Jnr and described in the American magazine Modeltec. I those sizes they ate much easier to make.

Stick to injectors, far easier!

Regards,

Bob

|

|

|

|

Post by suctionhose on Sept 2, 2016 23:15:03 GMT

I hesitated to post at all because of a complete lack of being able to follow up with useful information!

Sincere apologies. How commercially available items are designed is the intellectual property of those that have done the hard yards and so it should be.

Of course I usually pull them apart to see "how he did it" but not my place to spill the beans other than general guidance in the right direction!

|

|

|

|

Post by joanlluch on Sept 3, 2016 6:02:07 GMT

Really this ought to linked to Joan's recent thread. Cheers, Julian Well, of course the thread Julian is referring to is this one modeleng.proboards.com/thread/11618/donkey-blower-blast-superheated-steamIt doesn't matter whether we continue there or here, though this one began with greater speciality on the subject of steam pumps. Julian, if you don't mind, please I would like a copy of the article(s) you mentioned which are relevant about (working) steam pumps published in ME. Thanks. |

|

|

|

Post by joanlluch on Sept 3, 2016 8:35:14 GMT

Bomba Vapor Horitzontal Bomba Vapor Horitzontal by joan lluch, on Flickr What about this one (from holzapfeldampf.ch)? Leaving aside any attempt at realistic look, that pump is simplicity at its best. It's made in the same country that was once famous for the reliability and precision of their 'Swatch' watches back in the 80's and earlier, and known by their multi-purpose 'army knifes'. But in this case I have serious doubts that this pump will work at all. I can't identify any latch mechanism, and how do they make sure the sliding valve is not stuck in an intermediate position? Or maybe, the actual steam valve is hidden in the interior and what is shown is a trip valve just piloting the main one? |

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on Sept 3, 2016 8:43:54 GMT

|

|

|

|

Post by joanlluch on Sept 3, 2016 8:54:39 GMT

I don't like "imperial" (I don't quite understand it). If you want metric sized pumps I believe these ones from dampfmodellbau.de are just the same, and they look great.  |

|

jma1009

Elder Statesman

Posts: 5,925

|

Post by jma1009 on Sept 3, 2016 10:21:58 GMT

Hi Joan, Your interesting 'Vapor Horizontal' pic is very much like the smallest Southworth pump. There is a slide valve worked by a trip mechanism off the pump piston rod. This type requires 'crossed' passages inside the cylinder block as each port for the valve feeds the opposite end of the cylinder. If the trip mechanism is pivoted in the middle as per most of the LBSC type, then the 'crossed' passages are avoided. Between the above valve (which as Bob states can be a piston valve instead of a slide valve) is a 'shuttle valve' of piston valve type which isnt connected to any mechanism and floats freely in a separate steam chest to which the steam passages go to before being directed to one or other end of the cylinder. In the Westinghouse type, the trip mechanism is via a rod within the piston rod. The shuttle valve is on the top at 90 degrees. It can be arranged in the same plane as the cylinder and slide valve. In a scale 5"g version the drilling accurately of the stainless piston rod to fit a tiny push rod of sufficient strength is difficult to say the least, plus I am pretty sure you also need crossed passages. Bob has my greatest admiration for even attempting to make this type to scale, and getting it to work! Lisa's link to Warrick Sandberg is very interesting. His smallest pump is way too big for a scale pump on a UK prototype in 5"g, as is the smallest Southworth pump way too big. The smallest Southworth pump is also only single acting on the pump side, which seems a shame and a waste of all the considerable effort in making the steam side with it's slide valve, crossed passages, and shuttle valve. Some years ago I sketched out a spring operated single acting pump that avoided a lot of the above complications. No shuttle valve would be required, and the steam piston would always return to the same position. Incidentally Pete (Doubletop on here) has built the smallest Southworth pump and described it's construction and a list of amendments and errors on the drawings madmodder.net/index.php/topic,4763.50.html You can see most of the Southworth drawings in the above thread Cheers, Julian (Edit - I cannot get the above link to come up with the correct thread - you need to go to 'Project logs' then find the Southworth pump thread around 2011) |

|

jma1009

Elder Statesman

Posts: 5,925

|

Post by jma1009 on Sept 3, 2016 10:56:50 GMT

The very clever Richardson design is described by E G Rix in an article in Model Engineer 'Simplex Valve Gears' ME 19th April 1956.

This article covers all the different types of steam operated feed pumps and I suggest is a 'must' for anyone interested in the subject.

Another favourite of mine is an article by Jack M Fesco 'Making a Boiler Feedpump' ME 22nd April 1962.

Cheers,

Julian

|

|

|

|

Post by suctionhose on Sept 3, 2016 12:05:04 GMT

Julian et al,

The Sandberg pump for 5"g standard gauge locos ie the 1.125" to 1ft scale. I know the "true scale" for standard gauge is 1.062" to 1ft but we here have adopted 1.125" because our wheel standards are for a thicker flange and wider treads and that lends itself to the slight over scale with the advantage of slightly larger and more durable locomotive. In the light of the locomotives, castings and rolling stock that have been produced here, 1.125 is the logical choice of scale for the local market.

Our NSW engines were required to descend the Blue Mountains requiring the capacity of large pumps and later, grade control equipment on wagons that allowed the main reservoirs to be recharged without releasing the brakes. The operating conditions on the LBSCR are rather different I suggest hence the smaller pumps.

All that said, the valve principles still apply. Reading above the adoption of a "piston" type pilot valve sounds risky. How to make a piston valve of about 3/16" dia seal well and still move at a nudge?

The pilot valve in the Sandberg is a slide valve with curved face operating against the side of a reamed hole. I think this is a good feature because the valve seats properly (unless lifted off by a bent trip rod) and has the friction necessary to hold position once knocked on by the trip.

Again apologies for not "having the drawings' but I see no reason why the fundamental principles could be equally applied to a pump of smaller external dimensions.

|

|

|

|

Post by joanlluch on Sept 3, 2016 19:01:50 GMT

The very clever Richardson design is described by E G Rix in an article in Model Engineer 'Simplex Valve Gears' ME 19th April 1956. This article covers all the different types of steam operated feed pumps and I suggest is a 'must' for anyone interested in the subject. Another favourite of mine is an article by Jack M Fesco 'Making a Boiler Feedpump' ME 22nd April 1962. Cheers, Julian Julian, Thanks for your explanation. Actually, what you describe about the Westinghouse pump is similar to this Autocad plans that I found several days ago. The only difference is the shuttle valve is nor at 90 degrees but fitted vertically in parallel with the trip valve www.john-tom.com/html/SteamPlans3.html(Go towards the bottom of the page and search for "Steam Pump AutoCAD Plans") I wonder if you can send me a copy of the articles from 1956 and 1962. I don't have access to it, so it would be appreciated. Thanks. |

|

|

|

Post by joanlluch on Sept 3, 2016 19:16:21 GMT

Hi Julian et all.

I believe that a steam pump can be made to work without an intermediate shuttle valve.

Based on the horizontal pump mentioned earlier, I can imagine the trip rod to operate directly a sliding valve to feed the cylinder in the usual way (just crossed passages) but without any intermediate valve. In addition you need to fit some mechanical mechanism acting as a latch that forces the trip rod to one of the two extremes. The single trip valve would just flip to the opposite side as the main piston nears end of travel. The flip mechanism can be similar to a mechanical electric switch.

|

|

|

|

Post by Jim Scott on Sept 3, 2016 20:31:28 GMT

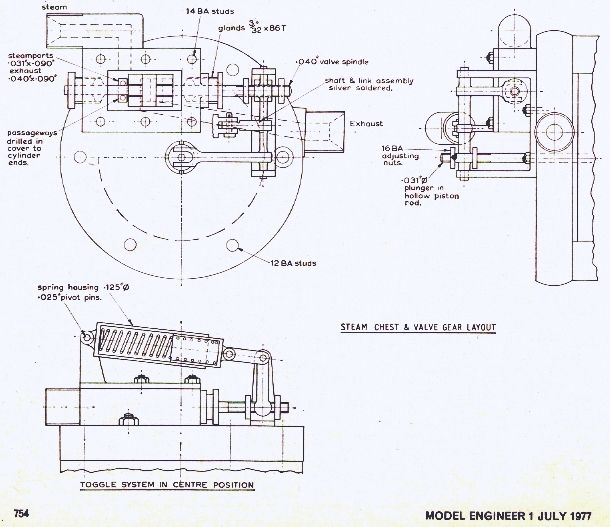

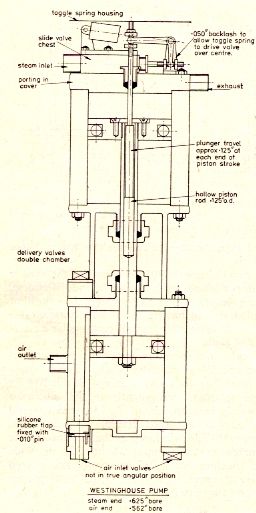

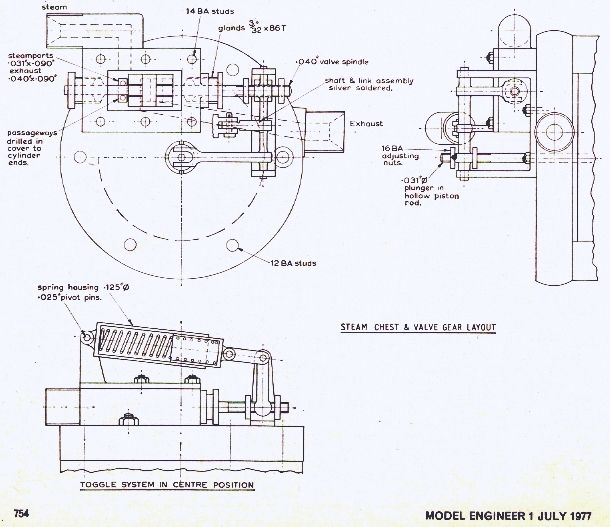

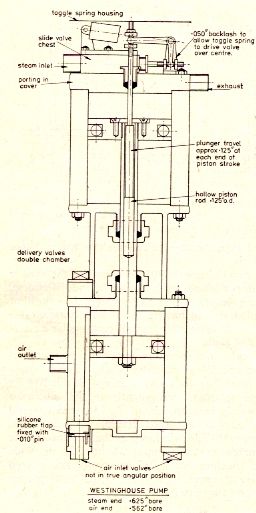

Hi Joan This is Roy Amsbury's over-centre type valve design from 1977. The general arrangement of his Westinghouse pump is shown in the second photo. Full article in Model Engineer July 1977 Jim S   |

|

jma1009

Elder Statesman

Posts: 5,925

|

Post by jma1009 on Sept 3, 2016 20:48:08 GMT

Hi Joan,

The reason for the floating shuttle valve is that the trip mechanism throws the (what Ross calls) the pilot valve, and slide valve in my description, to each extreme. There is no expansive working as such.

If the main piston in the steam cylinder stops part way without the slide or pilot valve being tripped, then the shuttle valve tells the steam which end of the cylinder to go to actuate the main piston. This is very much a simplification of an explanation.

I will certainly try and copy the Rix article for you with the Richardson design included. I dont know of any double acting pump that doesnt have some form of shuttle valve.

Rather like injectors, these gadgets are the sort of thing one person gets to work perfectly, and the next person working to the same design says their's wont work!

Ive never made a steam pump, but is on my 'to do list' just for the fun of it. However all my injectors work!!

Cheers,

Julian

|

|

|

|

Post by joanlluch on Sept 3, 2016 21:41:14 GMT

Hi Jim.

It's interesting that so many times I come out with an idea on something I haven't seen before and it turns to be that it was already tried long ago.

In this case the design you posted above, I think it has a potential flaw that in a very particular case can let the pump to a stall. On the above pump the trip rod actuates the toggle system which in turn is directly linked to the valve. This is wrong because as the trip rod pushes the toggle, the steam valve will travel to the neutral position as the toggle nears the central position. This may potentially stall the pump with the valve in the neutral position just before the toggle would actually switch, in a state that no or very little steam is fed to the main cylinder. Any minor misalignment between the toggle central position and the valve neutral position will enhance this problem.

The correct design would be to have the piston actuate on the toggle mechanism (still through a trip rod). Then the toggle will actuate the valve through a second trip rod. This arrangement makes sure the valve will only switch AFTER the toggle has already switched, thus preventing the engine to stall in a near neutral position. Basically you need something that advances the toggle with respect to the valve. Maybe the design above has already this, but it's not clear from the plans posted.

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Sept 4, 2016 4:22:46 GMT

Bomba Vapor Horitzontal Bomba Vapor Horitzontal by joan lluch, on Flickr What about this one (from holzapfeldampf.ch)? Leaving aside any attempt at realistic look, that pump is simplicity at its best. It's made in the same country that was once famous for the reliability and precision of their 'Swatch' watches back in the 80's and earlier, and known by their multi-purpose 'army knifes'. But in this case I have serious doubts that this pump will work at all. I can't identify any latch mechanism, and how do they make sure the sliding valve is not stuck in an intermediate position? Or maybe, the actual steam valve is hidden in the interior and what is shown is a trip valve just piloting the main one? G'day Joan The pump pictured is somewhat similar to my vertical pump although my pump is better laid out to look like a Westinghouse air pump. I think the pump pictured has a separate shuttle which controls steam to the main cylinder. The separate shuttle can be dispensed with if there are springs between the push arm and the tappets on the valve spindle. such that the movement of the main piston compresses a spring but the valve spindle is restrained by a latch. At either end of the stroke the valve spindle latch is released to allow the compressed spring to push the valves' spindle to the alternate position and reversing the steam inlet/ exhaust connections. Ian |

|

|

|

Post by joanlluch on Sept 4, 2016 9:20:46 GMT

Hi Ian, I understand that. So the compressed spring basically adds temporary extra force to the latch and 'displaces' (advances) the effective toggle central position with respect to the valve neutral position thus adding some hysteresis to the system and preventing it to stall.

|

|