Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 6, 2020 19:40:20 GMT

So today I dismantled the Rob Roy. The stiffness was not the bent frame as I thought it was very nasty gunk in the cylinders resembling dries up graphite grease! The pistons are packed with graphited yarn and I guess the gunk is the result of whatever oil was put In and the graphited yarn. WD40 cleaned it up nicely and the pistons seem a good fit. What should I do to reinvigorate the graphited yarn? The slot in the piston is 1/8” x 1/8” so I am guessing I wouldn’t be able to get a Viton o ring that size. All the jointing surfaces has been made with red hematite rather than gaskets. I am wondering what sort of gasket I could use that would not upset the alignment of the valve gear too much? I also found packers between the cylinder block and frames. I guess these were to resolve con rod alignment issues I will measure to see what if anything is not to book dimensions to see if there is another solution. Also the cylinders were bolted to the Frame with 3BA brass screws that look like they are almost sheared I have no idea what kind of force could do that. The good news is the frames are much less bent than I thought. The only real issue is the deflection behind the rear stretcher that. Is about 3/32” at the buffer beam. The apparent bend at the guide bar bracket isn’t apparent with everything stripped off. As for what it is going to end up like, my preferred prototype AB 885, seems to have a significantly longer wheelbase and overall length. Typically 6 coupled Barclays are longer in wheel base than the Caly pug Rob Roy was modelled after, however when you start to look at the prototype Martin Evans made a lot of changes anyway. I am continuing research on possible Barclays to model but if I go this route it will not end up an accurate model of any particular engine. There are a couple of distinctive features common to Barclays that would be good to do if possible. One is safety valves on the dome. Is there any reason why this can’t or shouldn’t be done ? The saddle tank will have limited water content. Is there a minimum I should consider? Also the saddle tank water will likely get warm. I presume attempting an injector rather than the cross head pump would not be a good idea? I will also need to relocate The hand pump. One option would be a small tank in the bunker another a well tank under the back of the cab floor any pros or cons to either of these ideas? sorry no pictures today the board full message comes up when I try and attach them and linking is producing image not found icons. I really can’t get the hang of reliably posting pictures here! cheers Kevan  |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,988

|

Post by JonL on Jun 6, 2020 19:46:31 GMT

Can you not just use fresh graphited yarn?

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 6, 2020 19:51:09 GMT

Can you not just use fresh graphited yarn? I suppose so, are you doing that on your William? Who supplies it these days? |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,988

|

Post by JonL on Jun 6, 2020 19:55:47 GMT

Kennions, Reeves, all the usual suspects. I have used it on my William but only because the original builder did. I've used high temp O-rings on my Britannia as that one I've built virtually entirely myself so far (not very much made). The William is someone elses locomotive I purchased unfinished from the builders daughter about 75% complete.

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,857

|

Post by uuu on Jun 6, 2020 20:21:42 GMT

Safety valves on the dome are fine but, as with all things boiler related, discuss with your boiler inspector! Having a water supply from your driving truck will overcome any warm water issues with injectors. Injector vs axle pump is very much a personal choice. Either can be good or horrible depending on how well they're set up.

Wilf

|

|

|

|

Post by ettingtonliam on Jun 7, 2020 6:03:11 GMT

O rings need piston grooves of closely controlled dimensions, to ensure the right amount of 'squeeze', not too little or they won't seal, too much and you won't move them. Graphited packing is much more tolerant, so I'd suggest that you stick with that if thats what your pistons were made for.

|

|

|

|

Post by Shawki Shlemon on Jun 7, 2020 10:13:16 GMT

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 7, 2020 21:30:30 GMT

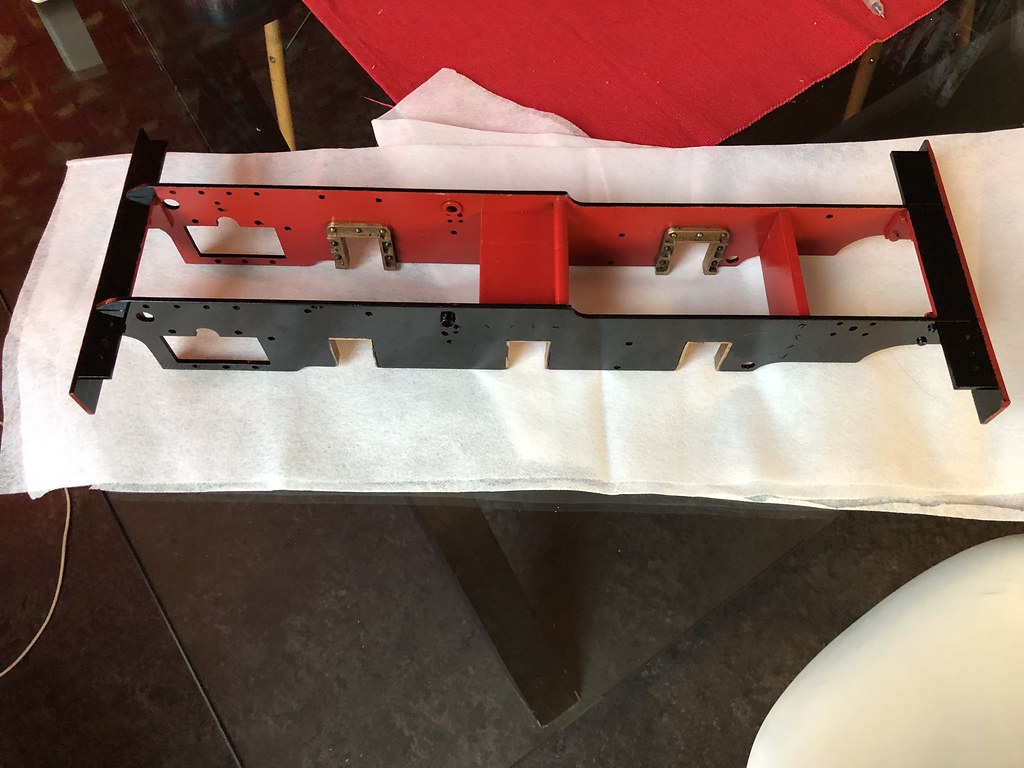

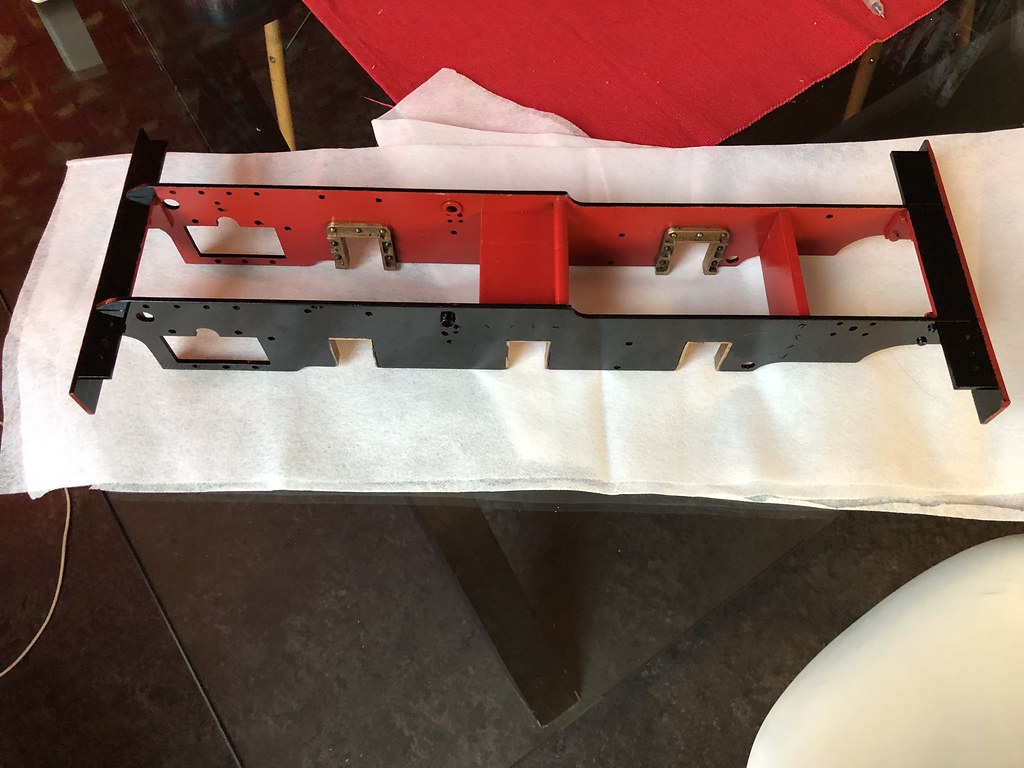

photos.app.goo.gl/rATr5E9VGtVd37XH8Today I straightened the frames!  this was pretty successful. I did resort to the hide faced hammer with the frames in the big vice with copper jaw protectors . I also applied a jack bolt to get rid of a narrowing and to prevent any problems with flexing in the frame while applying the patent adjuster:) Overall the frames vary in width by about 5 thou, I presume this is an acceptable tolerance. i also stripped and started the paint. Etch primer followed by signal red on the inside of the frames and buffer beams. Black on the rest when I het the paint. Another issue Is that one of the leading axle crank pins is loose in the wheel any ideas how is best to fix it. I am presuming Loctite might work? Kevan:)

|

|

don9f

Statesman

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Posts: 961

|

Post by don9f on Jun 7, 2020 23:15:24 GMT

Hi Kevan, today I was looking through some online photos/videos of engines that have been sold recently by a well known uk company and came across this Barclay “lookalike” and thought you might be interested in seeing it? It’s been adapted from a Rob Roy..... Cheers Don |

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Jun 8, 2020 0:49:21 GMT

Hi Kevan and welcome. Some of us have been on here many years and have too many projects but they do often help each other out with problems solved. ibb.co/Gk8B47gShowes my Simplex now with inclined Cylinders and a longer Wheelbase. In fact very similar to the Jinty wheelbase so no problems there. Done of course to miss completely having an axle in the middle of the ash pan. I have also moved the boiler up much higher which improves appearance and helps when I eventually fire her. ibb.co/R03DDC9Shows our Gemma with a just taken photo of her domestic setting. Now 32 years old having built her as the articles came out originally. It also shows that I can finish off a project. Most of the bits were done on an old table rescued from a skip in Enfield in a Bedsit. Perhaps a fully equipped workshop with far too many distractions spread upon 3 benches is not the ideal!!! Job for Lily in the morning is to dust her!! David and Lily. |

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,857

|

Post by uuu on Jun 8, 2020 6:30:36 GMT

Well done on the frames! I would consider Loctite on the crank pin. Is it rattle-loose, or just slides out? Rattle-loose might need an alternative approach. Make sure it's not contributing to the stiffness - no good cementing it in, if it's slightly off. Needs to be really clean for the glue to work properly.

Wilf

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 9, 2020 7:06:17 GMT

Wilf the pin is rotating when I tried to unscrew the crank pin screw so fit is stiff. Next question is what type of loctite is best for this?

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 9, 2020 7:09:01 GMT

David and Lily, Gemma looks really good ! Can you point me in the direction of the build articles and drawings? That looks to be a project I would like to add to my wish list!

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 9, 2020 7:53:57 GMT

Don

That loco is something like I was thinking of. A lot of problems have been fixed on the basic Rob Roy, the cross head driven water pump and lubricator for a start, also the hand pump under the cab floor. I have written to them asking to be put in touch with the builder or owner to get some info on that.

One challenge with fitting an axle pump is the wheel sets are made up and I don’t really want to take them apart to fit an eccentric. I am wondering if it would be possible to make a split eccentric and fit it over the completed axle? Is this a daft idea?

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,857

|

Post by uuu on Jun 9, 2020 9:14:56 GMT

Split eccentric is not at all daft.

Wilf

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 11, 2020 21:18:39 GMT

Hi again, here is what I have been up to this week. The frame is painted. insert code here Sketch GA Sketch GA by Kevan Shaw, on Flickr I also spent some time looking through old slides of pugs that I shot in 1971 and 72. These two, the last steam locomotives that worked in Edinburgh at Niddrie land sale yard.  Niddire No 19 Niddire No 19 by Kevan Shaw, on Flickr  No 25 Niddrie No 25 Niddrie by Kevan Shaw, on Flickr So after staring at Sketchup for an hour and a half trying to build a model and resorted to pencil and tracing paper assisted by a scanner and printer to develop the following outline over the Rob Roy GA  Sketch GA Sketch GA by Kevan Shaw, on Flickr There are a couple of issues. The boiler centreline is too high and the diameter is too large. The result is a bit of proportional distortion. At the moment I have drawn No.19 and am just concerned it is a little Thomas the Tank engine proportions, what do you all think? Solutions would require boiler mods, at the least shortening the firebox by about quarter of an inch to drop the boiler in the frames, the rear horn guides nearly touch the firebox. The other issue is the smokebox length and saddle overhang, this is more cosmetic and more easy to deal with. So what is the opinion of the forum? Kevan  |

|

mbrown

Elder Statesman

Posts: 1,788

|

Post by mbrown on Jun 12, 2020 11:37:42 GMT

With a saddle tank loco, the boiler diameter is concealed to a great extent. The larger boiler means a smaller tank, but as the capacity would be small in any case, you'd need a separate tank on the driving truck for an injector, so it wouldn't make much difference if the saddle tank was smaller. You could, at a pinch, reduce the smokebox to a slightly smaller diameter than on Rob Roy - which would be OK if you have small fingers for assembling the pipes inside.....

Personally, I think your sketch looks the part. Go for it!

Malcolm

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 13, 2020 9:07:32 GMT

Ok. Next advice needed. The axels are all made up however I would like to re-face the rims to separate them from the balance weights. The axles do not have Centre’s drilled. Is it advisable to put the wheel in the lathe and try to turn the opposite wheel? Should I try and drill centres on the Axles so I can support them or is this asking for more trouble?

I would be chucking on the tires which doesn’t give a lot of contact area, I am guessing trying with the 4 jaw would be the better way to go. The wheels are nominally 3”.

Any suggestions appreciated!

Kevan

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,857

|

Post by uuu on Jun 13, 2020 9:19:00 GMT

If you have (or can borrow) a "fixed steady" for your lathe, you could hold one wheel in the chuck (four jaw preferred) and support the other end on the bearing journal, in the fixed steady. Then you could either machine like that, or for extra security, put a centre in the end of the axle.

Wilf

|

|

Kevan

Seasoned Member

Posts: 138

|

Post by Kevan on Jun 13, 2020 9:21:27 GMT

If you have (or can borrow) a "fixed steady" for your lathe, you could hold one wheel in the chuck (four jaw preferred) and support the other end on the bearing journal, in the fixed steady. Then you could either machine like that, or for extra security, put a centre in the end of the axle. Wilf Wilf nice idea but I can’t get the wheel through my fixed steady to reach the axle:( |

|