choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Jan 25, 2021 0:44:26 GMT

I think you're right there Dave, it would purely come down to the material's properties, I don't think they would be bolting the horns on Prince of Wales if they thought the wheels were going to fall off whilst flying down the mainline.

On my horns, I am deviating from the prototype slightly. I might try proper rivets on the bogie to see if its possible.

Connor

|

|

Neale

Part of the e-furniture

5" Black 5 just started

5" Black 5 just started

Posts: 283

|

Post by Neale on Jan 25, 2021 8:06:38 GMT

Is there an advantage that rivets will swell to fit the holes, so providing some degree of location, where you would need fitted bolts in more accurate holes to get the same effect?

|

|

coniston

Statesman

Posts: 908  Member is Online

Member is Online

|

Post by coniston on Jan 26, 2021 23:38:42 GMT

Just a quick one today, a friend of mine has printed some parts while I wait for my printer to arrive. Here is a quick close up of the horn blocks. Connor Hi Conner, just out of interest which 3D printer have you ordered? so many to choose from. Chris D |

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Jan 27, 2021 9:02:05 GMT

Hi Chris, I ordered the Prusa MK3S kit.

A friend of mine bought one recently and he was very happy with it. I’ve had some experience using Flashforge printers, but the Prusa really jumped out at me.

Connor

|

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Jan 27, 2021 9:04:47 GMT

Is there an advantage that rivets will swell to fit the holes, so providing some degree of location, where you would need fitted bolts in more accurate holes to get the same effect? That’s an interesting thought, and probably partly the reason they used rivets. If only we could wind the clock back and ask Edward Thompson (or any of the CMEs). Connor |

|

coniston

Statesman

Posts: 908  Member is Online

Member is Online

|

Post by coniston on Jan 27, 2021 22:00:38 GMT

Hi Chris, I ordered the Prusa MK3S kit. A friend of mine bought one recently and he was very happy with it. I’ve had some experience using Flashforge printers, but the Prusa really jumped out at me. Connor Excellent another Prusa owner, good decision. That is at least four of us now. Mine arrived in November and after building and calibrating I think it has been used almost every day. I was initially put off buy the price compared to all the Chinese ones but after joining a number of FB groups for each of the printers I was looking at it became obvious the Prusa was well worth the money for the lack of problems. Chris D |

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Jan 28, 2021 1:09:24 GMT

It was no competition really, the Prusa is just the no nonsense design and I was happy to pay a small premium for, well, premium.

Connor

|

|

|

|

Post by 92220 on Jan 31, 2021 18:05:45 GMT

Hi Dave (Kipford)

When I thought more about your comments, I had to agreed with you, that there are bolts that can provide a stronger joint than rivets, nowadays, but probably weren't available in the days of steam railways. However, I did a bit of investigating on the web, and it would appear that that is not quite correct, and it appears that rivets can provide a stronger joint than bolts. This is what I found:-

When is it better to use rivets rather than screws?

By Michelle Froese | February 3, 2020

Written by Dr. Jody Muelaner

Screws provide convenient disassembly and reassembly while rivets provide economical and reliable fastening.

The choice of using threaded fasteners, such as machine screws, or rivets depends on many factor and is complicated by the wide range of fasteners available.

The advantages of machine screws and bolts are easy disassembly and reassembly, the ability to reuse the fastener, and the availability of such fastening tools. Some advantages of rivets include resistance to vibration, low-profile heads, and the rapid, low-cost assembly where large numbers of fasteners are required.

For typical workshop applications, where pop rivets are usually used, threaded fasteners will provide superior strength. Pop rivets use a hollow shaft, reducing their ability to resist shear loads. The strength of the materials used also depends on the power of riveting tools available.

Light-duty riveting tools are only able to upset aluminum rivets, which provide low-strength fastening. Heavy-duty pop rivet tools can install higher strength fasteners, such as stainless steel, but their strength is still limited by the requirement for a hollow shaft. A benefit of the hollow shafts and softer metals used for pop rivets is that it makes removal relatively easy. A drill bit can be easily seated in the hollow end and used to remove the head.

By contrast, solid rivets are perhaps the strongest mechanical fastener available. They are available in high-strength steels and aerospace alloys, and their solid shaft is able to transmit the greatest possible shear force for a given hole size. This is higher even than possible for a threaded fastener since threads create potential crack initiation sites. Furthermore, once the heads of a solid rivet are formed the fastener is almost completely immune from vibration.

For these reasons solid rivets continue to be the preferred fastener for critical applications such as aircraft structures and steel bridges. The disadvantages of using solid rivets are that highly specialized and costly installation equipment must be used which requires good access from both sides of the assembly. Additionally, they are difficult to remove.

Hope that clarifies things a bit. I know it helped me understand the advantages/disadvantages better.

Bob.

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Feb 2, 2021 10:06:52 GMT

Bob

I totally agree with the above in the context of which it is written, which is the use of machine screws compared to rivets. In my world (Aerospace) a 'machine screw' is a fastener threaded all the way to the head, it does not have the plain shank of a bolt and you would never use such a fastener in a high shear and/or tension joint, particularly one subject to cyclic loads and vibration. A ‘fitted’ bolt will always have the same or better load carrying capability than a rivet. I think we should stop here and not take over the OP’s thread with joint design discussion. Please feel free to disagree, this is just how we do things in Aerospace.

Regards

Dave

|

|

|

|

Post by 92220 on Feb 2, 2021 10:22:05 GMT

Hi Dave.

I fully agree. Your explanation is what I was trying to show but didn't make it anywhere near as clear. I wasn't on the aerospace side but I was a design engineer at Dowty fuel systems for some years, designing aircraft fuel systems test equipment, in their test facility drawing office, so I should have been a bit better at my description. I plead age as a factor!!!

Bob.

|

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Feb 2, 2021 12:08:29 GMT

This is all very interesting regardless of what the thread is about. I’m inclined to believe that a proper machine screw would be stronger in certain application. Where vibration is a concern I think the rivet would perform better as well. Thank you for posting that information and sharing your thoughts.

I’m the context I’d be using it, the choice would come down to being prototypical, if rivets were what the railways used then I guess I will have to find a way to make that work. A plastic rivet in two parts that force fit together? I’ll have to do some testing...

Connor

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Feb 2, 2021 15:35:59 GMT

Connor

You are correct a machine screw can be made to output perform a rivet, particularly where you get any tension component in addition to shear in the loading, rivets do not like tension, but you do not do it in joints which are safety critical. You can often use less bolts than in a riveted joint. I could bore you silly with instances where I would use rivets or bolts or both on applications and the trade offs you do in mass, mechanical performance (stress, fatigue life etc), cost and maintainability to decide what is the best. With regards to loco horn blocks no doubt rivets are used mainly to reduce costs as the joint is considered permanent and there are lots of applications in loco chassis where fitted bolts are also used. Good luck with what ever fastener you decide on.

Regards

Dave

|

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Feb 6, 2021 14:32:35 GMT

Thanks Dave. I had this file ready to go for some time now.  A bit of sanding required to make smooth but should be light work. Until next time, Connor |

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

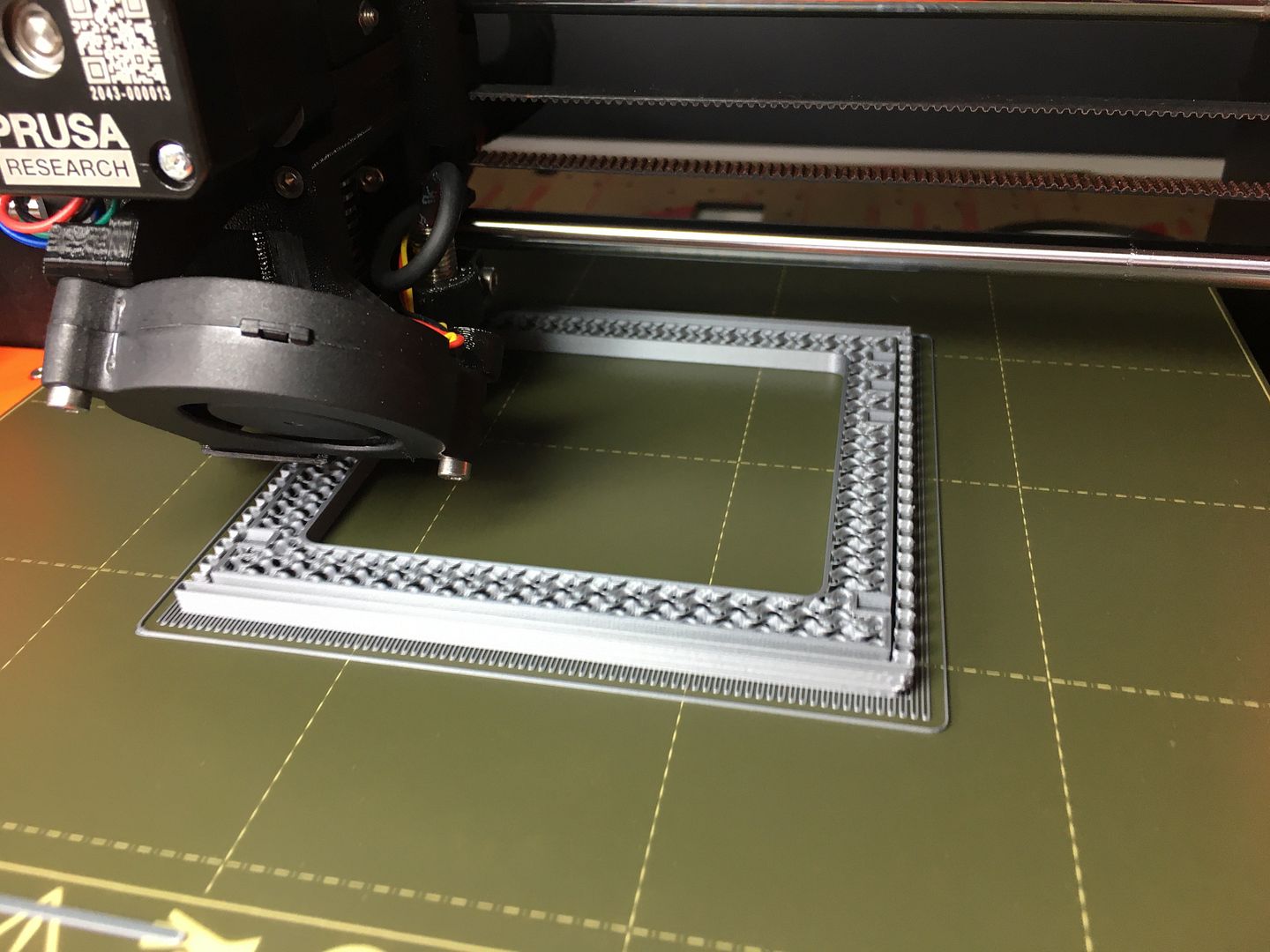

Post by choochooenthusiast on Feb 27, 2021 5:13:18 GMT

Good News! My printer arrived, so naturally I spent a few evenings neglecting my homework to build it. The kit went together nicely I'm pleased to say. Here's 20% of a smokebox saddle for you:   Wish I could make these images smaller. Connor |

|

|

|

Post by Deleted on Mar 24, 2021 18:55:18 GMT

Hi guys

I've also been thinking about a 3D printer... I note that the Prusa seems to be popular here, is this the Geetech Prusa? I see that Amazon have a fair list of 3D printers available at reasonable prices including the Prusa?

Pete

|

|

coniston

Statesman

Posts: 908  Member is Online

Member is Online

|

Post by coniston on Mar 24, 2021 22:49:57 GMT

Hi guys I've also been thinking about a 3D printer... I note that the Prusa seems to be popular here, is this the Geetech Prusa? I see that Amazon have a fair list of 3D printers available at reasonable prices including the Prusa? Pete As far as I am aware you can only buy a genuine new Prusa direct from Prusa. The Prusa is an open source product hence so many copies using the name Prusa, but they are only copies and each and every one has their problems. I spent along time researching most popular 3D printers before I settled on a genuine Prusa. The best advice I can give you is to join the Facebook groups for the printers you are interested in and like me you will soon find the shortfalls of each one, join the Prusa FB groups and you will see very little in the way of complaints about the failures of the product. Like everything in life you only get what you pay for. If on the other hand you want another hobby and you like tinkering and rebuilding / upgrading / modifying then some of the Chinese 3D printers are certainly good value for money as a starting point. The Prusa is my second printer so I had already gone through the initial learning curve and journey of modifications, I bought the Prusa because I was happy to invest in a machine that just works straight out of the box with top quality components included and not just copies / clones. (yes I am a Prusa convert so maybe a little biased now  ) Happy to discuss further if you feel like it Chris D |

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Mar 25, 2021 6:26:32 GMT

Some very good points raised there Chris! The genuine Prusa may cost more but its has better quality components and a much bigger community of owners. There are some good clones, but for me at least, Prusa all the way!

|

|

|

|

Post by Deleted on Mar 25, 2021 10:53:35 GMT

Thank's guys.. I'll do some research into this subject, I'll ask my son too, he may have some insight having used them at work...  Cheers Pete |

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Apr 6, 2021 1:16:11 GMT

No worries Pete, good to get a few people's opinion.

I've been talking to Doug Hewson about his new B1 drawings. I have the drawings for the tender so I've started work on that. Thought it would be better than trying to correct Martin Evans Springbok. I have done a fair bit of work already on the Springbok but I figured I'd start again with the new drawings.

More on that soon...

Connor

|

|

choochooenthusiast

Involved Member

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Building a 3D printed Crab 13065. A wagon (or a few) in the works.

Posts: 70

|

Post by choochooenthusiast on Apr 11, 2021 5:42:17 GMT

Well here I was about to show some progress made on the drag boxes but photobucket has disabled my account.

Apparently hosting photos goes against their terms and conditions. I've read some of the other posts about it. Looks like I have to pay up or switch sites AGAIN. Everything has a price tag these days, even just sharing some project you're working on.

|

|