JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Apr 19, 2021 20:10:43 GMT

My locomotive regulator handle was made by the person who started my locomotive. The handle has never been that tight on the square. The square is very small, I estimate around 1/8" each side.

My options for making a replacement seem to be the following:

1) Drill a 0.125 (or whatever the actual size is) hole and use a needle file to make it square by hand.

2) Make a tiny broach from silver steel. Not done this before, will be interesting but possibly a push of my skills as they stand at the moment.

3) Try and find a suitable broach (probably a better bet than me making one), possibly from jewellers or similar? Its an unusually small size.

4) Buy a rotary broach (not happening; I just don't have the funds).

Are there any other options I might be missing? I guess my most likely option is 1), but if I can do it 2) is a possible.

As usual, thanks for the tips should you have any.

|

|

|

|

Post by simplyloco on Apr 19, 2021 20:26:20 GMT

My locomotive regulator handle was made by the person who started my locomotive. The handle has never been that tight on the square. The square is very small, I estimate around 1/8" each side. My options for making a replacement seem to be the following: 1) Drill a 0.125 (or whatever the actual size is) hole and use a needle file to make it square by hand. 2) Make a tiny broach from silver steel. Not done this before, will be interesting but possibly a push of my skills as they stand at the moment. 3) Try and find a suitable broach (probably a better bet than me making one), possibly from jewellers or similar? Its an unusually small size. 4) Buy a rotary broach (not happening; I just don't have the funds). Are there any other options I might be missing? I guess my most likely option is 1), but if I can do it 2) is a possible. As usual, thanks for the tips should you have any. Hi Jon. Drill the 1/8" hole. Fit a sq needle file in the drill chuck and work the quill up and down until you have what you want. John |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Apr 19, 2021 20:31:00 GMT

Thanks, I can't believe I forgot about square needle files. What is wrong with me.  |

|

|

|

Post by simplyloco on Apr 19, 2021 20:35:15 GMT

Thanks, I can't believe I forgot about square needle files. What is wrong with me.  Just wait until you get to my age...😈 |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Apr 19, 2021 22:35:13 GMT

Hi Nobby, if you fancy having a go at making a square broach, check out Clickspring on YouTube. He makes a small broach in the lathe in his making spare parts video series, part 13. Hope this helps.

Mike

|

|

|

|

Post by terrier060 on Apr 19, 2021 23:20:23 GMT

It may help to drill four small holes at each corner before you drill the large central hole and use the square needle file. It gives you guidance and you get a better square.

Ed

|

|

|

|

Post by cplmickey on Apr 20, 2021 7:49:26 GMT

i got a set of very small broaches from Proops. Think the largest in the set is only about 6mm, the smaller ones go down to under 3mm. Ian

|

|

jem

Elder Statesman

Posts: 1,075

|

Post by jem on Apr 20, 2021 16:13:50 GMT

You could get 4 square pieces of steel and silver solder them together round a 18 square piece of metal, and then turn down the outside to suit. I have done this on bigger sizes with good success.

best wishes

Jem

|

|

|

|

Post by 92220 on Apr 20, 2021 16:47:11 GMT

I have to admit, when I wanted some 3mm square holes in some tiny levers, I paid for the holes to be spark eroded by a small sub-contract company. It cost me around £40.00 including postage, and the accuracy of the resulting holes was such that they were a close slide fit on the 3mm square shaft ends.

Bob.

|

|

|

|

Post by andyhigham on Apr 20, 2021 17:09:41 GMT

If you drill a 1/8" or slightly smaller get it nearly to size with the file method, then take a piece of 1/8 square HSS or silver steel (will need hardening) and grind the corners off at a taper over about 25-35mm. Lubricate it and press it through the hole, this will give a good finish to the hole with sharp corners.

Instead of cutting the final size it moves the metal, the principle is the same as fluteless taps for copper or rolled threads on spokes, valve guides in IC engines are often sized by pressing a steel ball through

|

|

|

|

Post by 92220 on Apr 20, 2021 18:35:35 GMT

That sounds a good idea Andy. I must try that the next time. A lot cheaper than spark eroding!!

Bob.

|

|

|

|

Post by cplmickey on Apr 20, 2021 18:57:24 GMT

I have to admit, when I wanted some 3mm square holes in some tiny levers, I paid for the holes to be spark eroded by a small sub-contract company. It cost me around £40.00 including postage, and the accuracy of the resulting holes was such that they were a close slide fit on the 3mm square shaft ends. Bob. Never thought of that and our spark eroder at the club workshop doesn't get enough use in my opinion. Making an appropriate copper bit should be quite straightforwards. |

|

|

|

Post by David on Apr 21, 2021 9:23:47 GMT

If the square hole in the current handle is ok but oversized you could use a shim folded 90deg. I had to do that on my mogul when the milling machine cut the square on the regulator spindle undersize despite not having moved the head after cutting a test square to a good fit!

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Apr 21, 2021 12:09:57 GMT

I think I'm going to use the opportunity to remake it into a two armed regulator; it will be easier for my son to drive

|

|

|

|

Post by Oily Rag on Apr 21, 2021 22:02:05 GMT

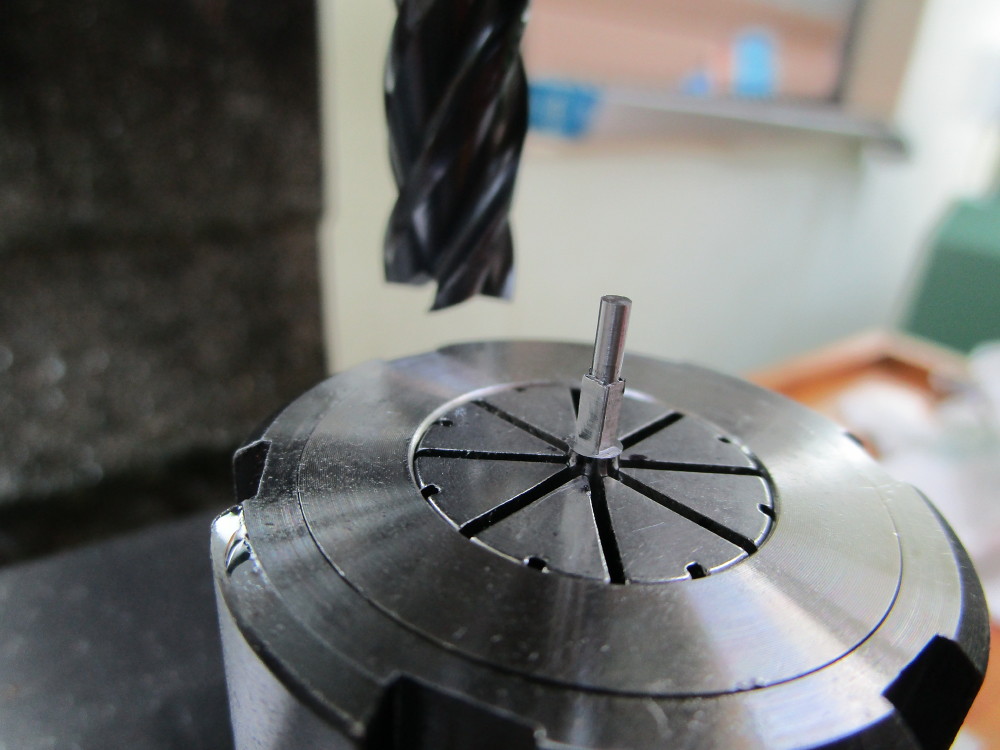

I have for the first time just done this as a skill acquisition process for things to come later, it is a smaller hole at 1.70mm square. Milled silver steel held in collet block.

For the servo operated blower valve.

|

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Apr 25, 2021 23:57:43 GMT

I think I'm going to use the opportunity to remake it into a two armed regulator; it will be easier for my son to drive There is a lovely photo on The Steam Workshops Web Site of a double handled Handel. I so fancy one of these for several of my models. Jessie of course as the Loco in question is the 7 1/4" Cadburys one also by Avonside. Full size measurements from Tyseley the next time they have an open day. David and Lily. |

|

|

|

Post by durhambuilder on Apr 29, 2021 20:50:42 GMT

I have broached square holes using the square ends of broken taps, a touch on the grindstone to give a concave end helps.

|

|

|

|

Post by dhamblin on Sept 27, 2024 21:56:24 GMT

Just bumping this back to the top as I need to make a 3/32" square hole in a piece of 1.5mm mild steel as a replacement lever for the blowdown valve (the old one has a hole that is no longer fully square nor uniform 3/32" across!).

I think the best option is Dazza's silver steel mini-broach tool as I can't find any easily sourceable small needle files that will fit through the pilot hole nor any reasonable price square broaches or rotary broaches. A quick question - what heat treatment is required to suitably harden it up?

Thanks,

Dan

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Sept 28, 2024 13:26:46 GMT

This works for me on broaches that 2 - 3 mm square. Heat to a nice red heat, then plunge into oil. Clean it up, then temper to light straw.

Dave

|

|

jasonb

Elder Statesman

Posts: 1,246

|

Post by jasonb on Sept 29, 2024 6:04:01 GMT

I'm not sure why you can't find a needle file to suit, they all go down to a point so fitting sufficient into a 3/32" hole should not be a problem. These were done with a needle file and are only 1/16" square  |

|