|

|

Post by suctionhose on Sept 26, 2022 11:12:04 GMT

I recently made an injector to DAG Brown specs but used a nitrile ball in it. I'm sure it's ability to work dry down to 10 to 15 psi is related to an excellent seal on the ball. It lifts and picks up perfectly at under 20 psi. I've never seen one like it!

|

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Sept 27, 2022 22:29:26 GMT

I don't think that a 'chirping' injector is necessarily an issue. I don't think it has that much effect on performance. I've run locos with 'chirping' injectors that will feed down to 15 psi.

What Ross probably has (I assume) is a very smooth finish

on the bores and everything else perfect.

The stainless balls supplied by the trade are not as accurate as we might assume. Roger's balls that he popularised (can't remember tonight the name for them) are far superior. I have definitely had dodgy batches of stainless balls supplied by the trade.

|

|

|

|

Post by suctionhose on Sept 28, 2022 4:03:46 GMT

Julian, I'm flattered you assume me capable of perfection! I think I just got lucky... I have been paying attention to people saying "the ball must seal well" hence moving to a nitrile ball.

I'm also told that drawing air in through the injector is detrimental to steel boilers. Makes sense. One uses treatment to scavange oxygen from the boiler water so injecting a stream of microscopic bubbles could be counter productive. Bubbles are certainly hard on centrifugal pump impellers...

A fellow involved with full-size heritage steam here mentioned a non return valve on the overflow to prevent air being drawn in.

|

|

|

|

Post by simon6200 on Sept 28, 2022 4:11:21 GMT

Silicon nitride balls are another option. They have a high degree of roundness but are not cheap. The last injector I made was a Brown 12 oz but with a Viton O-ring arrangement for a perfect seal. It works perfectly and also lifts.

Everything Ross does is perfect. You should see his latest ploughing engine. Quite annoying really.

|

|

|

|

Post by suctionhose on Sept 28, 2022 7:50:18 GMT

Perfection is just a 'successful hiding of the flaws'...

|

|

stevep

Elder Statesman

Posts: 1,073

|

Post by stevep on Sept 28, 2022 9:01:07 GMT

I understood that 'chirping' is sucking in air. I guess that's not too big an issue with a copper boiler, but I imagine it would be undesirable with a steel boiler.

Putting extra air into the water would encourage internal corrosion.

|

|

|

|

Post by Roger on Sept 28, 2022 9:39:49 GMT

I understood that 'chirping' is sucking in air. I guess that's not too big an issue with a copper boiler, but I imagine it would be undesirable with a steel boiler. Putting extra air into the water would encourage internal corrosion. I agree, the noise is the ball unseating and rattling around. It's due to instability in the flow that keeps unseating the ball when too nuch water is drawn in when the regulation gap is too large for the current conditions. All of the standard commercial injectors with the single ball on the top allow air to be drawn into the Boiler. In my opinion it's a poor design, because not only is that undesirable from a thermodynamic point of view, it reduces the amount of water delivered and reduces the tolerance to higher water feed temperatures. A better design uses a single valve on either both separate overflows (yes, there are two, one is internal and feeds into the one at the delivery end), or better still a single valve on a combined overflow. My injectors with the single disc valve don't chirp even when the flow is unstable. |

|

|

|

Post by terrier060 on Oct 4, 2022 18:23:24 GMT

Hi All

I have been away having a well earned holiday on the Norfolk Broads. The weather was sunny almost throughout. Also visited a few pubs!

Interesting what you say Julian, as I have a nitrile ball in the chamber. I will have a look at the seat. I like the injector as it has a small enough flow to leave on almost all of the time. Boiler pressure does not drop and I can forget about it. I have a bigger one if I want to reduce the boiler pressure quickly to stop the engine blowing off.

I visited the Bure Valley Railway whilst I was up there and also saw the impressive large 00 layouts in the Wroxham Miniature Worlds Railways.

|

|

|

|

Post by flyingfox on Oct 5, 2022 6:26:59 GMT

Greetings Terrier 060, you should have come to see us at Parklands Railway, 10mins from Potter Heighham, and a great 71/4 gaue railway.

Let me know if you come this way again, sure something can be arranged.

Did you also see the short 71/4 gauge Barton House railway at Wroxham, on the south bank, 1/4 mile downstream from the bridge?

lots of railways to see here.

Regards

Brian B

|

|

|

|

Post by terrier060 on Oct 7, 2022 21:34:28 GMT

Hi Brian

I am really sorry I missed coming to your track. I was not aware it was there! Yes I did visit Peter at the railway at his house. I will be amazed if his locos manage the 1 in 30 grdient! It looked very steep.

Ed

|

|

|

|

Post by flyingfox on Oct 8, 2022 6:24:17 GMT

Yes Ed, you'r right & they will want good brakes, unless they want a swim.

|

|

|

|

Post by terrier060 on Oct 31, 2022 11:28:23 GMT

The test boiler is now more-or-less ready for welding. I am machining the feet on the Tormach as I write this. I did away with the turret as Roger quite rightly said it just complicated the welding and it is relatively easy to make one in brass. I tried to machine the 1 inch BSP thread, but it looks really messy and the welders said they would run a tap through to clean it up. I may ask them to shorten it as it is 500mm long which would be a lot of water to boil using a 2500W element. I shall now have to knock up some boiler fittings.  Injector Test Boiler Injector Test Boiler by ed cloutman, on Flickr |

|

|

|

Post by terrier060 on Dec 30, 2022 0:46:48 GMT

Happy Christmas and New Year everyone. I have been pre-occupied writing book on the SAS so have neglected the workshop, but the test boiler has now been expertly welded and I am soon to make a start on the fittings. i thought of buying the water gauge but at £250 I thought better of it and will probably make one, just with a simple blowdown valve. Pictures to follow.

|

|

|

|

Post by terrier060 on Jan 31, 2023 23:58:30 GMT

Thanks to Kyle and his colleagues at Pipework Mechanics Ltd in Pyle my test boiler is now welded and ready for the fittings and pressure testing. It was fascinating seeing the work being carried out in their workshop and Doug and I watched as they welded flanges on to these large pipes by their coded welders. On my pipe they had a machine which put the correct chamfer on the end of the pipe in under a minute. All I had to do was machine the end covers to the right diameter and drill and thread for the boiler fittings. Today I started making the water gauge. The bolt heads for the various plugs were machined on the Tormach. I am going to try and make a PTFE insert for the blow-down cock. If this works I will make shut-off cocks for the top and bottom fitting, but the design is a bit fiddly and may leak.  Welded Boiler Welded Boiler by ed cloutman, on Flickr |

|

|

|

Post by terrier060 on Feb 21, 2023 0:23:55 GMT

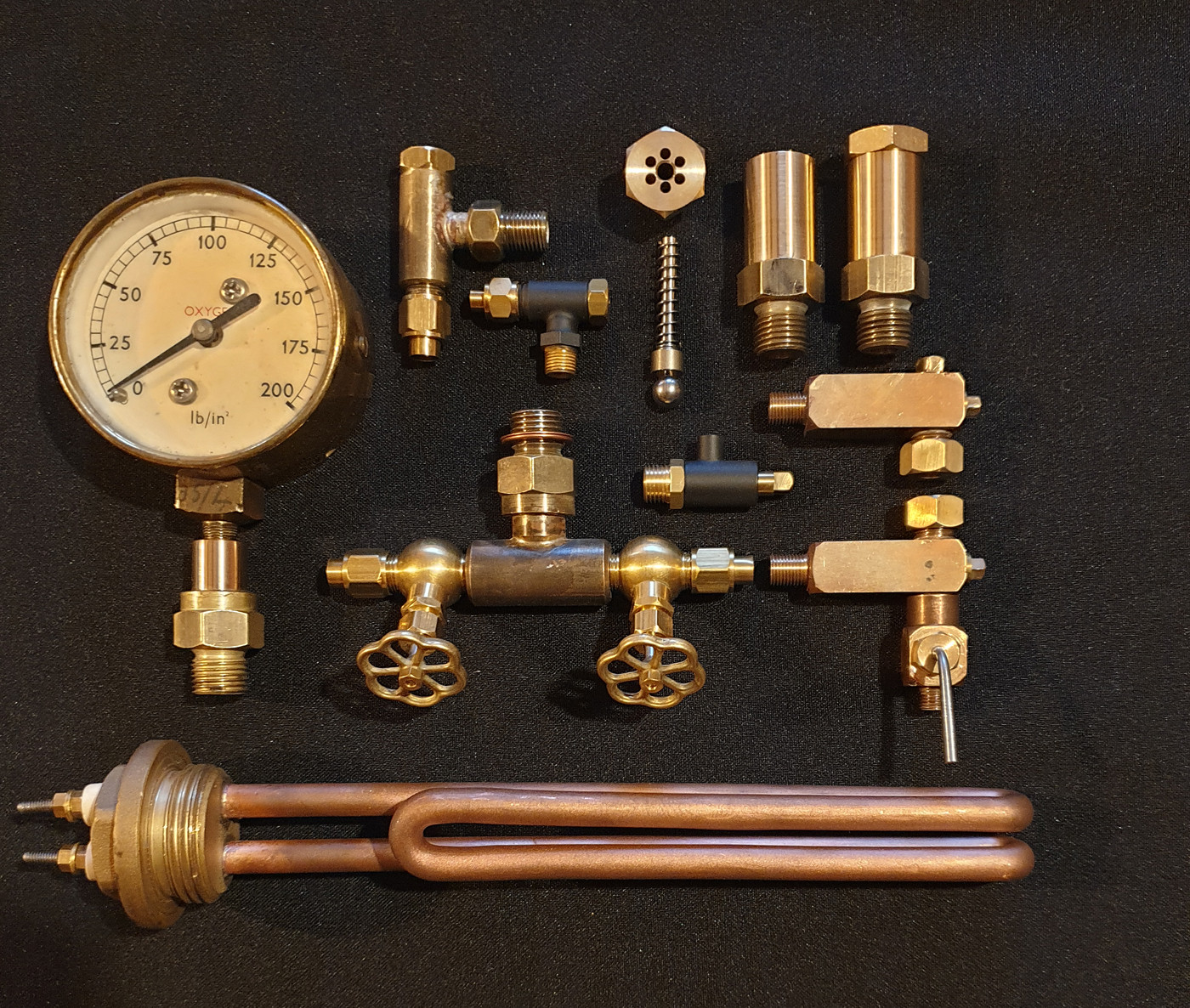

Few more fittings to make - safety valves and a clack, and a few plugs and then testing. The blowdown on the water gauge is a parallel cock in a PTFE sleeve. If it works I will post a drawing. The gauge glass is 5mm but I may bore it out to 8mm.  Fittings01 Fittings01 by ed cloutman, on Flickr |

|

|

|

Post by terrier060 on Feb 22, 2023 16:39:29 GMT

Strength of safety valve spring - I need one about one inch long, to fit a 5/32 spindle and give a working pressure of 100psi. Hole diameter is 1/4 inch with a 5/16 inch diameter stainless ball. I will draw a sketch, only I have made these as I went along without drawings! Any thoughts on spring strength?

|

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Feb 22, 2023 17:12:11 GMT

Looking at the photo above, does the pressure gauge have a syphon so that the mechanism is not exposed directly to steam? It's not clear from the photo.

A very solid looking piece of work! I will be interested to hear how the cock with the parallel PTFE sleeve works as I am considering something similar.

Best wishes

Malcolm

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,858

|

Post by uuu on Feb 22, 2023 17:22:19 GMT

Apart from the spindle diameter, Jessie and the Gordon Smith alternative I'm going to make have similar pressure, ball size and hole.

But the springs are shorter. Jessie is 1/8" dia 20SWG and 5/8" long. The Gordon Smith springs are also about 5/8" long but more like 1/4" internal dia. So your 1" springs are in danger of being a bit soft?

Wilf

|

|

|

|

Post by terrier060 on Feb 28, 2023 17:52:51 GMT

Thanks for the info. I have some odd springs I found lying around to give me some idea of the strength required. I can then order some stainless ones. Here are the boiler fittings. I have not made the top and bottom shut-offs for the gauge glass yet until I find out if the blowdown works. Then I will post the drawing. Tomorrow I will make the plugs and can hydraulically test the boiler to 200psi.  Boiler fittings Boiler fittings by ed cloutman, on Flickr |

|

|

|

Post by terrier060 on Mar 13, 2023 13:52:46 GMT

The boiler passed its shell test at 200psi and is shown here at 150psi with all the fittings. I need to check the calibration of the pressure gauge against the club one. The boiler will then be ready for a steam test. I think I went in for a bit of overkill as it weighs 25kg and taked 9.5 litres of water to fill it! The only fittings which leaked very slightly were the commecial globe valves (which was surprising as they are expensive ones) and my gauge glass blowdown, but I haven't given up on that as it may perform better when it gets heated and under steam pressure. I now have to make the pipework to the injectors and get suitable springs and set the safety valves.  On Test 150 On Test 150 by ed cloutman, on Flickr |

|