|

|

Post by Jo on Mar 11, 2008 13:47:22 GMT

Hi Guys,

Progress is slow on my Compound...... last weekend I finished the 28 hand rail posts and the crank oil pots. Progress so far only basic parts: Crank, Flywheel, Base plates and cylinders to size and bored. So I am at about the same stage as John.

It took some time to find a piece of suitable material for the base plate that was large enough and now that I have it just underlines what a large engine the cross compund with air pump is. Other than the sitting in the middle of the dining room table will be too wide to fit on any of my furniture!

I have just brought a replacement camera so I must take some photos....

In the uk we are having excellent workshop weather: plenty of rain and storms but I fear my 6 trees that came down in yesterday's storm and the extra ventilation caused in my greenhouse may stop any progress this weekend on the Corliss.

Jo

|

|

lancelot

Part of the e-furniture

Posts: 471

|

Post by lancelot on Mar 11, 2008 18:26:31 GMT

Please...some photos Jo, you are certainly cracking on with the build...I have not got near my shop lately as it is like Noahs ark, with the amount of rain of late... I work out of two sheds and would be dragging water from one to other so have to wait until things settle a bit. In the mean time the spare room has been commandered as a workshop, temporarily of course...What problems, if any with the flywheel machining?...Cylinders, did you bore between centres or other?...

All the best for now,

John.

|

|

Myford Matt

Statesman

There are two ways to run a railway, the Great Western way, and the wrong way.

There are two ways to run a railway, the Great Western way, and the wrong way.

Posts: 621

|

Post by Myford Matt on Mar 13, 2008 17:58:46 GMT

Looking forward to the pics Jo/John

Cheers

Matt

|

|

lancelot

Part of the e-furniture

Posts: 471

|

Post by lancelot on Mar 14, 2008 20:24:57 GMT

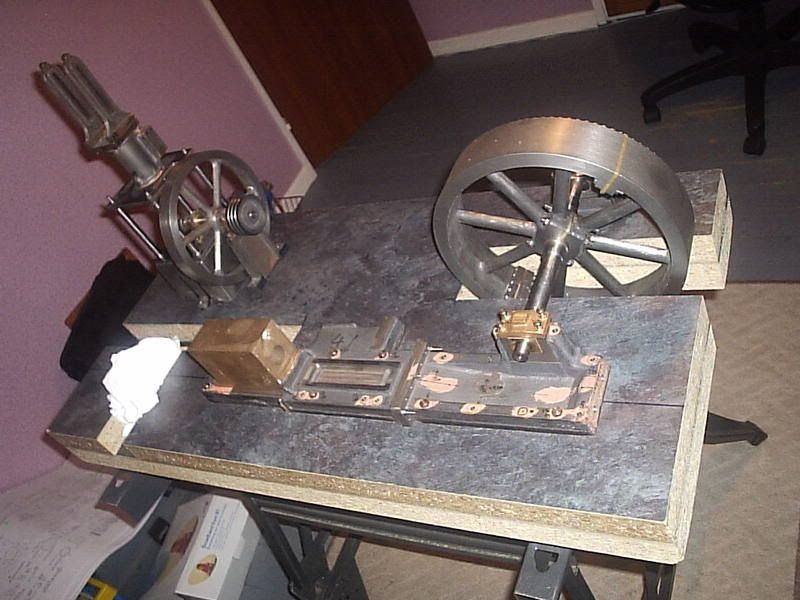

Hi all Corliss builders, a couple of belated photos of the current state of play with the Corliss, (and the Coombes)...Joe , the foundation for mine is constructed from kitchen worktop, two layers bonded together, 32'' /16'' /3'' ...it will be trepanned out on the under surface to reduce the weight  ...even without the air pump as yet , it is quite some size... once I get to finishing the Coombes and the piping e/t/c on the steam plant I will then be able to concentrate on the Corliss...   All the best for now, John. |

|

paul

Member

Posts: 8

|

Post by paul on Mar 14, 2008 21:09:05 GMT

Blimey, that's a whopper!

|

|

Myford Matt

Statesman

There are two ways to run a railway, the Great Western way, and the wrong way.

There are two ways to run a railway, the Great Western way, and the wrong way.

Posts: 621

|

Post by Myford Matt on Mar 17, 2008 19:32:42 GMT

Great work...

...adding the Coombes is a bit left field! :-)

|

|

lancelot

Part of the e-furniture

Posts: 471

|

Post by lancelot on Mar 17, 2008 20:26:38 GMT

Hello Matt,

thank you for that, but staying there it aint...

are you still considering the Corliss?... spotted a chap over in Home Workshop free ads. looking for Corliss castings info about a few weeks ago.

All the best for now,

John.

|

|

Myford Matt

Statesman

There are two ways to run a railway, the Great Western way, and the wrong way.

There are two ways to run a railway, the Great Western way, and the wrong way.

Posts: 621

|

Post by Myford Matt on Mar 17, 2008 21:25:43 GMT

Hi John

Definitely still thinking about it. I've had a good look through the drawings and while it's a 'biggee', I think I could see myself doing it - one day.

One small point - the con rods look strangely simple. I'd have expected more of a strap/cotter/gib type of affair. Any thoughts?

The chap in the free ads wasn't me - this Corliss thing must be contagious.

Somewhere on the web (Bolton steam museum?) there are pictures of a Corliss beam engine, not sure if it was designed by Coombes though!

Cheers

Matt

|

|

|

|

Post by Jo on Mar 19, 2008 7:51:05 GMT

|

|

|

|

Post by jgb7573 on Mar 19, 2008 8:49:33 GMT

It's certainly a big engine. I retrieved a set of castings for a Corliss from storage last weekend (along with a milling machine and much else besides). If my memory serves me correctly they're for a tandem compound. That shouldn't be so wide but may well be longer. I'll have a look this evening. It'll be some time before I get to have a go at it though., A long term project.

|

|

lancelot

Part of the e-furniture

Posts: 471

|

Post by lancelot on Mar 19, 2008 14:20:29 GMT

Hi Jo,...looking very good, it certainly illustrates how big a model this is...Wee'l be calling ourselves ''Team Corliss'' next ;D

All the best for now,

John.

|

|

|

|

Post by Jo on Mar 19, 2008 15:15:50 GMT

Hi Matt,

You asked about con rods... Almost all the photos I have of these engines are of the solid big end rod type. I can only assume that as most of these rather large textile mill engines were producing hundreds (if not thousands) of hp of power the cotter/gib would have been a potential point of failure.

If the cotter failed on a strapped big end, with the potential for the strap to go flying, it would be likley to do no end of damage and take the mill out of action for some time. Failure of the solid end type, whilst expensive, the solid end itself would limit movement so cause less damage? Just a guess.

Jo

|

|

gugger

Active Member

Posts: 47

|

Post by gugger on Mar 19, 2008 16:16:28 GMT

Jo,

The ruler does not mean anything. Wait until you have to lift the biest about. ;D

Walter

|

|

Myford Matt

Statesman

There are two ways to run a railway, the Great Western way, and the wrong way.

There are two ways to run a railway, the Great Western way, and the wrong way.

Posts: 621

|

Post by Myford Matt on Mar 20, 2008 22:25:40 GMT

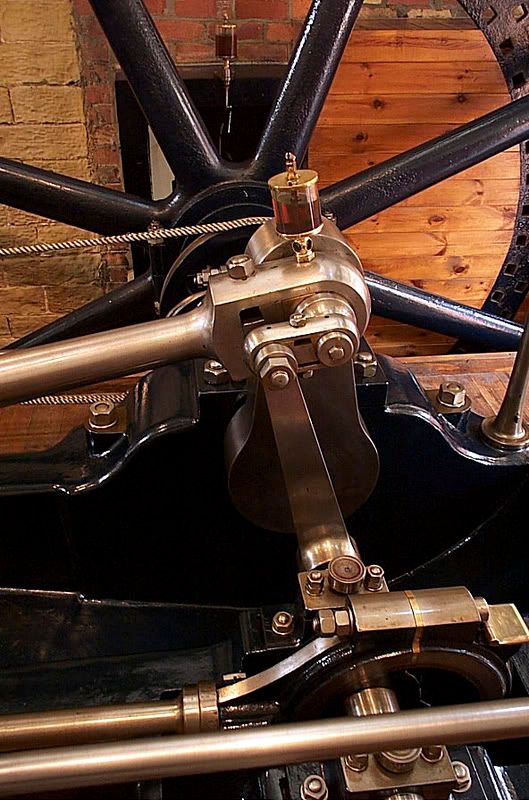

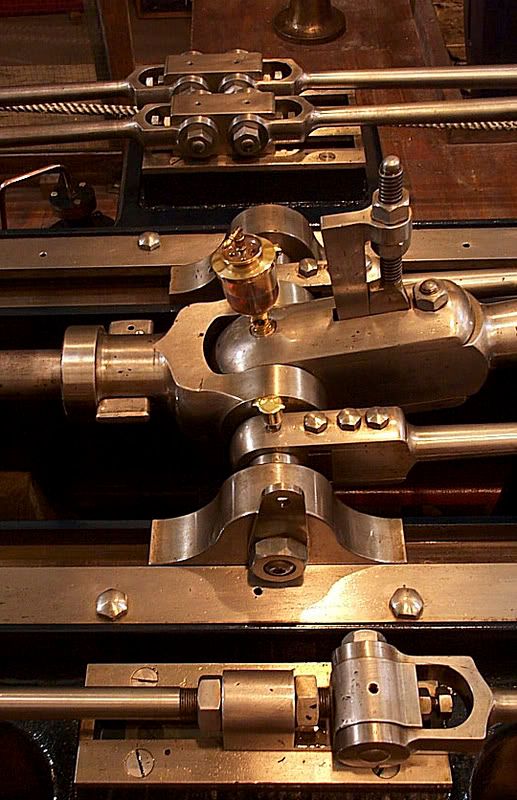

Hi Jo Lovely work - do keep posting. I understand what you say about the con rods, but I'm not sure I agree. You find straps/cotters/gibs on large beam engines, and also on some of the most powerful locos, which given the speed of the rotation must have put enormous strains on everything, so I'm not convinced that is an explanation. I had a look at some images of the very nice Corliss engine at Armley Mills and just to make life interesting we are both right! One end is solid and the other has all the bits and pieces I would expect:   It's well worth a visit if you are in the Leeds area, particularly when in steam - obviously! |

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Mar 21, 2008 23:34:44 GMT

G'day Matt

Thank you for the beautifully detailed pictures. Look at the provision for adjustment of the clearances on the bearings. Wedges are used with threaded ends to set them in position. Wonderful.

Having the lubricator on the big end indicates that this is a comparatively low speed engine. At higher speeds they would have used a wick and wipe system or one of those drip and collector systems. The latter couldn't be used on this engine because of the connection to the outboard eccentric.

I think the solid versus open arrangement shown has more to do with assembly. The big end is closed because it can be slipped over the crank pin, the little end has to be inserted in to the cross head and a closed end would make this more difficult.

On steam locos solid big ends can be used on outside cylinders, but split big ends were required for inside cylinders. You may not be aware that split roller bearings are available; very fussy with housing dimensions.

Regards,

Ian

|

|

Myford Matt

Statesman

There are two ways to run a railway, the Great Western way, and the wrong way.

There are two ways to run a railway, the Great Western way, and the wrong way.

Posts: 621

|

Post by Myford Matt on Mar 23, 2008 21:46:45 GMT

Cheers Ian - useful comments, not my pictures though. Pulled from their website. www.leeds.gov.uk/armleymills/armintro.htmlArmley mills is a much under-rated place. It's the original site of Matthew Murray's works. Murray so worried Boulton and Watt that they bought up all the land around him so he couldn't expand his factory. Matt |

|

lancelot

Part of the e-furniture

Posts: 471

|

Post by lancelot on Jul 12, 2008 15:05:38 GMT

Hello Walter, I hope you do not mind me congratulating you on your recent work on the Corliss build...beautiful...I regret to say I have not turned the lathe nor a screw for a few months... but I do hope to get there in the end...your photos are an inspiration to myself and hopefully others to follow this build...

All the best for now,

John.

|

|

gugger

Active Member

Posts: 47

|

Post by gugger on Jul 12, 2008 19:20:56 GMT

Thanks John,

I try to do my best. I have still a bit work left.

Walter

|

|

Myford Matt

Statesman

There are two ways to run a railway, the Great Western way, and the wrong way.

There are two ways to run a railway, the Great Western way, and the wrong way.

Posts: 621

|

Post by Myford Matt on Aug 7, 2008 22:09:55 GMT

Any more lovely Corliss pics?

MM

|

|

|

|

Post by Jo on Aug 11, 2008 7:30:37 GMT

Hi Matt,

Sorry no progress on my Corliss.

I was short of the steel to make the connecting rods when my Nephew reminded me that I had promised to teach him to drive "his" Clayton, which means I have to get my finger out and finish it.

Hope to return to it over the next couple of weeks.

Jo

|

|