|

|

Post by classicsteve on May 13, 2009 20:42:53 GMT

Tel (and others),

After getting hold of a wood and brass half-beam engine (see separate thread) I have been looking up these half-beam engines. There are a couple of things I don't understand.

First is that the beam is a dead weight, I would have expected some sort of counterbalance on the flywheel. I suppose it is handy to always know where it will stop, but I thought they would balance it out a bit more. It may not be critical on a model, but on a full sized engine that is a heavy beam, surely it would surge on the down-stroke.

The other is that a lot of the Easton and Amos engines have the valve chest offset towards the top end of the cylinder. Why did they do that ? Easton and Amos engines dominate the pictures I can find of half-beam engines.

The problem seems to be that these engines came and went in the 1803 to 1860 slot, so maybe the literature is scarce, but some of the gurus out there must have old books and piccies.

Steve

|

|

|

|

Post by Tel on May 14, 2009 8:45:24 GMT

Now I hadn't given that much thought Steve, but since you mention it ..... would the weight of the beam returning the engine to BDC at 'rest' mean that the engine was assured of being in the starting position, ie self starting? And if so, by accident or design? A fascinating question.

|

|

|

|

Post by Tel on May 24, 2009 21:25:21 GMT

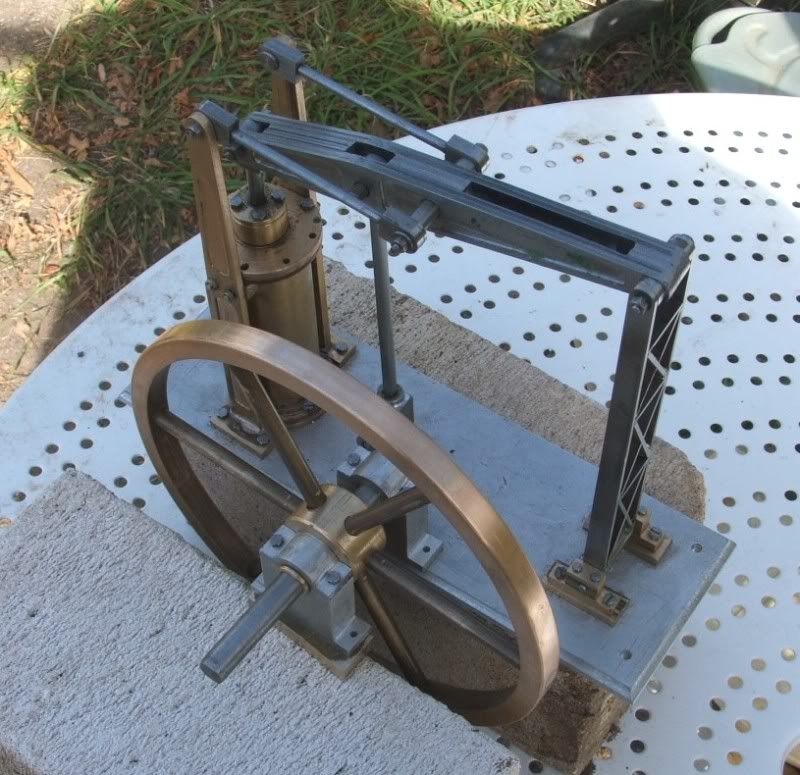

Disaster & recovery  a rough mock-up of the bits so far   |

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on May 24, 2009 22:24:01 GMT

G'day Tel

Great work.

Pity you didn't measure twice and cut once when cutting the stone plinth. ;D

Regards

Ian

|

|

|

|

Post by Tel on May 25, 2009 8:53:36 GMT

;D ;D Just a rough mockup with a couple off offcuts! When the time comes I will sculpt a base out of a new Hebel block.

|

|

lancelot

Part of the e-furniture

Posts: 471

|

Post by lancelot on May 25, 2009 10:23:49 GMT

''Hebel'' block  |

|

|

|

Post by Tel on May 25, 2009 10:50:37 GMT

Yep, these thingswonderful things they are - you can work 'em with woodworking tools - the abutments on this bridge on my (work in progress) G1 layout are made from them, siuably carved and stained  |

|

|

|

Post by Tel on Jul 31, 2009 9:16:27 GMT

Another small step towards completion  |

|

|

|

Post by Tel on Aug 20, 2009 11:21:59 GMT

Still moving forward - ever so slowly

|

|

|

|

Post by Tel on Aug 20, 2009 11:24:57 GMT

Shaped 'em up a bit this morning

|

|

|

|

Post by Tel on Aug 20, 2009 11:30:18 GMT

... and tried 'em on a bit of shaft

|

|

|

|

Post by Tel on Aug 24, 2009 8:12:06 GMT

Getty 'busy' around the steam chest now

|

|

|

|

Post by jgb7573 on Aug 24, 2009 9:34:02 GMT

Certainly is! Lots of gubbins there.

|

|

|

|

Post by Tel on Aug 24, 2009 10:53:50 GMT

Yep, and small gubbinses at that!

|

|

|

|

Post by Tel on Aug 30, 2009 2:54:45 GMT

|

|

|

|

Post by jgb7573 on Aug 30, 2009 17:52:34 GMT

Good use of filling buttons Tel. The last time I made an eccentric I machined the outside on the rotary table having calculated all the angles of where to stop the table. It worked OK but quite a fiddle compared with your method.

|

|

|

|

Post by rodwilson on Aug 30, 2009 21:13:57 GMT

Many Thanks Tel - an education I certainly enjoyed

Rod

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Aug 30, 2009 21:48:49 GMT

G'day Tel

I agree about the instructional values of you pictures which leads me to ask. "When are you going to post pictures of Ridley's Stripper?"

I wonder if the moderator would let me post such a photo?

Regards

Ian

|

|

|

|

Post by Tel on Aug 31, 2009 0:30:53 GMT

Thanks blokes, I did think of using the rotary table, but it would have taken me longer to set it up and then bugger about ..... Ridley's Stripper? A bit controversial ain't it Ian? Some say it was actually John Wrathall Bull's stripper.  |

|

|

|

Post by Tel on Sept 4, 2009 9:19:16 GMT

|

|