jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 16, 2008 21:16:04 GMT

Ahh, interesting, Tel. The leak is definitely much less now that I've been lapping - one drop every half hour or so, rather than every two minutes or so. Perhaps that's enough?

|

|

|

|

Post by Tel on Mar 16, 2008 21:24:24 GMT

Yep, I'd ignore it for now and see what happens

|

|

jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 16, 2008 21:51:12 GMT

Thank you - I'll see how it goes :-)

|

|

jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 22, 2008 22:54:48 GMT

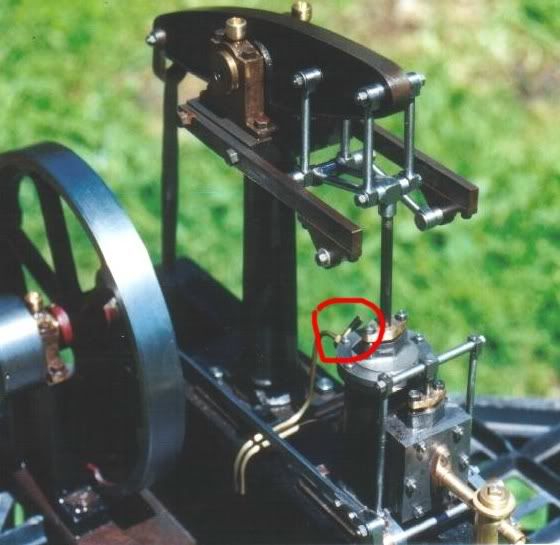

After a great deal of tinkering (and going through two gauge glasses: good job that I had spares!) I have finally got to the stage of pressure testing my boiler, and, having spent much of the evening tracking down leaks (and getting myself and the surrounding area quite wet in the process), I have succeeded in pressure testing my boiler to just slightly over 100psi (the gauge does not go higher, and I do not want to go beyond that, or else I might break it: I am aware that it would be better to test it to 120psi). Here are some pictures:   Although I have tracked down most of the leaks, there are still one or two small ones, including the one in the blowdown cock for the gauge glass:  a smaller one in the top fitting for the gauge glass:  and one in the line between the water pump and the check valve:  The last one is not a problem for boiler pressure, as it is the right side of the check valve, but the combined effect of the others is that the pressure is not maintained: after about 30-45 minutes, it drops from 100psi to 75psi. Would those small fittings leaks prevent a boiler from acquiring a certificate if it were tested? If so, any tips on how best to deal with the leaks? I have used kilometres of PTFE tape already. The leaks seem very small when the boiler is filled with water, but will they be more problematic, does anyone think, when, instead of 100psi of water, the boiler contains 60psi of steam? In any event, I plan to try firing it to-morrow, once I have drained some of the water and replaced and re-adjusted the safety valve to 60psi: the drain cocks on the engine also seem to leak somewhat (although, interestingly, not the one whose brass washer I broke and was replaced hastily by a section of copper pipe (my father's idea), packed with PTFE tape), as do the connecting rod and eccentric glands, although I appreciate that they are probably hard to seal properly. The valve for the whistle also does not seem to hold properly, but that is not a great problem, since I can readily close the globe valve leading to the whistle pipe. I shall use bicycle oil to lubricate the engine bearings and steam cylinder oil that I bought from Forest Classics for the steam cylinders, from my Mainsteam displacement lubricators. I shall not fit the pipes to the drain cocks until I have fixed the leaks in them, since it would be hard to unfasten the cocks once the pipes are installed and bent. For attaching the pipes to the cocks, any suggestions as to whether locktite is better or worse than silver solder? |

|

|

|

Post by Tel on Mar 23, 2008 4:24:25 GMT

With care you should be able to get a couple of turns of thread on the discharge end of the drain cocks and use a regular nut & cone. That's what I did with the Beam engine  |

|

|

|

Post by dickdastardly40 on Mar 23, 2008 7:21:21 GMT

James,

Any leaks on soldered joints will not bet any better when hot but on screwed fittings could go either way, ie stop or get worse.

Proof of the pudding etc.

If you fit a stop cock on your pressure gauge line you can pressurise to 100 PSI, isolate the gauge and put a few more pumps in or however your increasing the pressure, easy to see what pressure you have if a gauge on the pump input. This is how we vacuum test fridge plants to prevent damage to gauges which aren't compound.

Good luck.

|

|

jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 23, 2008 20:56:48 GMT

Interestingly, when I ran it this afternoon, those leaks were hardly noticeable (the drain cock leaked very slightly). There were far bigger leaks on one of the globe valves and one of the engine gaskets, the latter of which in particular sent clouds of steam all around.

Photographs and a video will be uploaded shortly.

|

|

|

|

Post by circlip on Mar 24, 2008 9:12:59 GMT

Perhaps I'm reading it incorrectly James but I get the inference that you did a pressure test using the Stuart gauge and with the boiler fittings ie. gauge glass valves taps etc in situ? Normally a pressure gauge with a top line in excess of your 2X working pressure would be used to do the hydraulic test and all the "holes" in the boiler fitted with blanking plugs so as not to put excessive strain on them. As far as using a larger test gauge is concerned, they tend to be more accurate and if you're going to run it "in public" a proper boiler test cert will be required. Ian.

|

|

jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 24, 2008 13:02:47 GMT

I test-steamed the engine for the first time yesterday. It ran quite well, although there were some leaks in the pipework (one on the gasket on one side of the engine, and another in a globe valve), and the silver solder joint on the whistle failed, leading to the whistle flying off (unfortunately, not captured on video) when blown at 60psi. I found, though, that the engine would quickly deplete the boiler's pressure, and that it was quite slow to build pressure again, suggesting that the ceramic burner was not producing enough heat. My father suggested raising the burner to put it much closer to the water tubes, which I shall try, and I suggested drilling another air hole into the bottom of the burner surround, since I noticed that, whenever I turned up the gas enough to maximise steam output, the flames were quite yellow; and also, the water tubes became quite blackened in operation. Does anyone else have any suggestions as to how to increase the efficiency/heat output of the gas burner? In any event, I have uploaded photographs and a video:    One of the globe valves leaked:  Video here. Edit: Incidentally, Circlip, I did indeed conduct the test with all the fittings in place - I rather thought that that was the idea, since the integrity of the fittings is just as important as the integrity of the boiler, since a failure of either is equally likely to lead to being scalded with hot steam. I am aware that a test by a duly qualified person is necessary to run the boiler in public, but it is useful nonetheless to conduct my own test in any event. |

|

|

|

Post by circlip on Mar 24, 2008 13:34:14 GMT

The object of the exercise in pressure testing is to check the integrity of the BOILER, not the fittings. What you have proved is that the fittings seem to be a very effective safety valve, it's just a little worrying that there is a possibility that if the fittings were steam tight you could still have a potentially dangerous assembly. The fittings are not supposed to work at twice the boiler rated running pressure, hate to think that if you tested with all the fittings in place including the safety valve,( how did you stop that blowing?) you were close to it. In this case it just goes to show that a correctly designed boiler was initially strong enough to do this with, dependent of course on its age. You made enough references to the fact you were a newbie to steam for us to pick up that you might not have tested something like this before, and I for one apologize for not pointing this out. We could have lost or at least had a new recruit injured. Not putting this lightly but people far more experienced than you or I have died due to boiler explosions, Ian.

Just as a PS on going back over your posting re the drop in pressure when "testing" a certificate would NOT have been issued, but a qualified boiler inspector would have told you what was wrong and how to fix it.

|

|

jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 24, 2008 14:30:43 GMT

Circlip,

thank you for your reply, although I am now somewhat confused: what do you mean by, "if the fittings were steam tight you could still have a potentially dangerous assembly"? I initially tested the boiler with the safety valve in place, but, of course, could not get above the rated pressure, so replaced the safety valve with a spare globe valve for the pressure testing, replacing the safety valve again before steaming.

As to the drop in pressure, given that the drop in pressure seems to have been caused by the fittings, and not the boiler itself, if the boiler test certificate is based on the boiler without fittings, that would not be an issue unless there is some as yet undiscovered defect with the boiler - unless it is the case that the boiler is pressure tested with the fittings in place, but not to twice working pressure...?

|

|

|

|

Post by circlip on Mar 24, 2008 19:08:43 GMT

I can't quote pressure regs James cos I ain't a boiler tester, but I do know that in the pre elfin days, it was ADVISED that the boiler should withstand twice working pressure and hold at that pressure for 24hrs. Pressures greater than 2X was deemed to be needlessly over stressing it, but again we are testing the integrity of the BOILER, thats the pressure vessel, NOT the fittings. If a fitting leaks it's a pain, if a boiler bangs, that's a REAL pain.

I often get annoyed at people not reading these posts thoroughly before replying, but must hold my hand up to not reading properly your post No23 Regards, Ian

|

|

jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 24, 2008 19:09:10 GMT

After the first run revealed some inefficiencies, there are a number of things that needed working on: (1) fix leaks in the globe valve and gasket; (2) re-silver solder the whistle; (3) clad the pipes; (4) re-clad the boiler; and (5) raise the gas burner to place it closer to the water tubes and drill an extra air hole in the bottom of the jet ring. So far, I have made an attempt at no. 1, and have made (with assistance from my father) partial progress at nos. (3) and (4). Pictures: Original boiler cladding removed:  The idea is to put the layer of kaowool underneath a layer of copper to keep the friable kaowool from disintegrating, looking awful, and presenting a dust hazard. Here is the copper cladding:  The cladding on the boiler (the kaowool not yet in place - this is for testing):  Cladding the pipes with string and PTFE tape:  |

|

jamespetts

Hi-poster

Closet eccentric. Also bakes cakes.

Closet eccentric. Also bakes cakes.

Posts: 185

|

Post by jamespetts on Mar 30, 2008 20:02:22 GMT

More progress this week-end as pictured below: Copper shroud for holding in place and protecting the friable kaowool insulating material completed and painted:     Firebox riser to lift the gas burner higher so that the flames are nearer the water tubes and heat the boiler more effectively completed:  Copper inset for firebox to protect the kaowool from damage by the burner cut and painted:  And, finally, some nuts and screws on the engine tightened to remove rattles that were present during the first steaming:  |

|