barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878  Member is Online

Member is Online

|

Post by barlowworks on Jun 16, 2017 13:32:08 GMT

Why not follow this to its logical conclusion and put a thread on the overflow pipe so it can be unscrewed to empty the tank. If you castellated the top to the overflow level or drilled opposing holes you could even unscrew it with a tommy bar and still not get your pinkies wet.

Mike

|

|

|

|

Post by 92220 on Jun 16, 2017 16:05:19 GMT

Taking Mike's idea to the Nth degree, Have the overflow tube in line with the water scoop and instead of taking in water, the scoop can discharge the overflow and later on, empty the tender! All that is needed is a removable dome over the water scoop, and the overflow tube feeding into the scoop. Hmmm. That's got me thinking! I'm just drawing up my water scoop arrangement for Mike's castings, at this moment!

Bob.

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878  Member is Online

Member is Online

|

Post by barlowworks on Jun 16, 2017 16:51:29 GMT

All you need is enough joined up thinking and you'll eventually get a sentence

Mike

|

|

|

|

Post by Jim on Jun 16, 2017 22:59:09 GMT

More ideas! My head's spinning with these great ideas.  Seriously they are much appreciated and actually I have already marked out the position for the overflow pipe to be directly beneath the water scoop's dome. Making the pipe removable to become the drain is something I hadn't considered though so I must give that some more thought. My head aches. As you must have realised by now I'm more or less making the internals and assembly of the tender up as I go. The Perrier drawings I have apart from being faded are as far as I can tell, correct regarding dimensions when compared to to the Hewson drawings or my works drawings. Things get interesting though when you add the variations that occured across the different marks of BR1 tenders to find them lumped together in a drawing labelled simply 'BR1 tender'. Actually sorting it all out is a bit of fun helped with some good photos taken over the years. Today's job is to a) be disciplined and not hare off making overflow pipes / drain pipes just yet. b) stick to the current job which is to trim the other tender side to size. and c) start marking out the plate for the back of the tender. Jim |

|

|

|

Post by Jim on Jun 19, 2017 6:24:12 GMT

The supplies from Ben at E J Winter arrived today. Included in the parcel was the half round beading for the tender so naturally I had to fit a length.  Fitting beading can easily turn to custard if something moves or comes unstuck. To avoid these ' Oh bother' moments I first tinned both the flat base of the beading and the upper edge of the bunker side. I then lightly tacked the end I intended starting from to give fixed end. Next I used an aluminium straight edge to butt the beading and side against to ensure all remained nicely in place before starting the job of carefully sweating the beading to the side. The photos show the jig to keep the beading aligned along with the finished job. Slowly getting ther. Jim   |

|

|

|

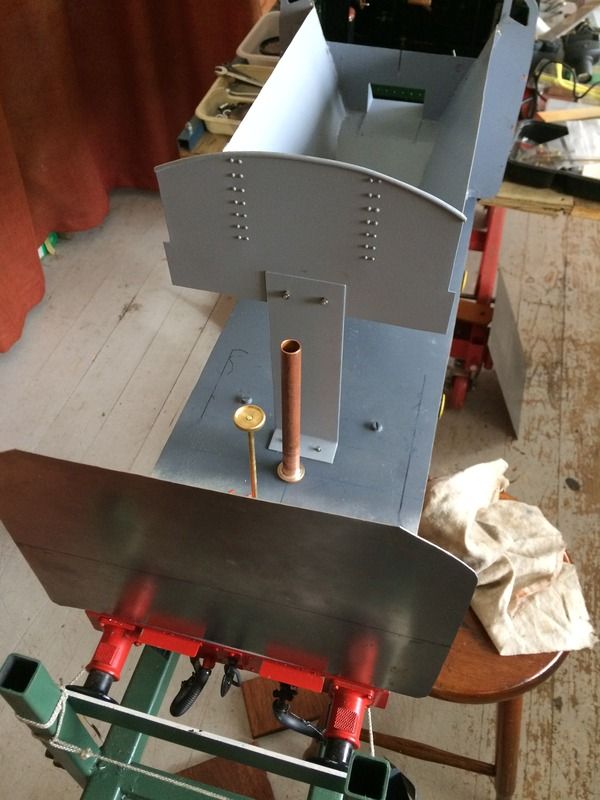

Post by Jim on Jun 24, 2017 7:52:14 GMT

Things are now moving along quite nicely with the beading completed except for finishing the corners which can't be done until the upper sides are properly secured at the ends. The end of the tender has been roughed out and will secured it to the sides once final checks for squareness etc have been made. The first photo shows the components of the bunker in place primed but not fixed permanently in place.  The second photo shows the tender end in place so I can determine the fixing points. In cases like this I prefer to cut the component slightly over size then fix it in place before carefully trimming to the final shape to fit the sides. I've already decided to use the end hand rails as securing points holding the end to the square stock already soldered in place on the right hand side. I'll do the left tomorrow. I must say the magnetic angle holding plates are a handy bit of kit to have for jobs like this.  This method of assembling the tender is the one that suits me but there are many other ways to go about the task and in the end it's all about finding the way that you feel most comfortable with. Now the crackle of the fire is sending out enticing calls plus there's a nice red there too. Don't laugh the sun has started its journey back South.  Jim |

|

|

|

Post by 92220 on Jun 24, 2017 8:13:07 GMT

Looking good Jim. Just a word of warning. If that is a piece of rail, in the photo, from the batch you got in to run your loco on, it's a bit over-scale and the wheel flanges won't be quite deep enough. It's also a bit difficult to bend!

Bob.

|

|

|

|

Post by Jim on Jun 24, 2017 9:24:04 GMT

Gosh Bob you're right and it seemed a good idea at the time too.  I suppose I could use it as a door stop.   Jim. |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878  Member is Online

Member is Online

|

Post by barlowworks on Jun 25, 2017 8:35:09 GMT

Hi Jim

I've sent you a PM.

Mike

|

|

|

|

Post by Jim on Jun 25, 2017 10:08:41 GMT

Hi Mike,

I've just replied and hopefully clarified a couple of things.

Jim

|

|

|

|

Post by Deleted on Jun 26, 2017 13:50:05 GMT

I have already marked out the position for the overflow pipe to be directly beneath the water scoop's dome. Making the pipe removable to become the drain is something I hadn't considered though so I must give that some more thought. My head aches. An overflow pipe is a fancy idea, but I don't think it will be of much practical use. If you fill your tank from a hose fed at mains pressure (as most of us do when public running) the water will come out of the hose much faster than it could ever drain out of the tank under gravity. Not worth bothering with, IMHO. |

|

|

|

Post by Cro on Jun 26, 2017 16:49:39 GMT

I have already marked out the position for the overflow pipe to be directly beneath the water scoop's dome. Making the pipe removable to become the drain is something I hadn't considered though so I must give that some more thought. My head aches. An overflow pipe is a fancy idea, but I don't think it will be of much practical use. If you fill your tank from a hose fed at mains pressure (as most of us do when public running) the water will come out of the hose much faster than it could ever drain out of the tank under gravity. Not worth bothering with, IMHO. Have to disagree here slightly, big enough pipe copes with it fine as long as you don't set your overflow right under the level of the tank. I have seen countless times people overflow as they aren't paying attention or can't see the level with a hose in the filler cap. It's more of a sign the tank is full to then turn the tap off then to act as a constant overflow if you left the tap running. |

|

|

|

Post by Jim on Jun 26, 2017 21:08:54 GMT

I fitted the over flow pipe yesterday and I certainly don't see it as a fancy idea but rather a good one for preventing flooding of the tender. I don't fill the tender from a hose at mains pressure but prefer using a watering can which is much more controlled, I carry one as part of my kit just in case and our club has a constantly filled can/cans at the main station for topping up.

Jim

|

|

|

|

Post by Deleted on Jun 26, 2017 22:39:36 GMT

OK, horses for courses. On a relaxed club track with few people present, you can take as much time as you like to gently add water from a watering can or whatever. On a busy track like ours, where the public are queuing up for rides, you get maybe two minutes to fill your tank, put the injector on, attend to the fire while the train is loading and then you're off again. Our hoses are mains fed with with petrol pump style triggers, very easy to control but boy, does the water go in fast!

|

|

|

|

Post by Cro on Jun 27, 2017 6:19:31 GMT

Still disagree Ron, down at Beech Hurst we are on the go the whole time but never has this been an issue, like I said its more of an indicator the tank is full than an overfull to stop it coming over your lap! Either way, Chop chop Jim we want to see her in steam  |

|

|

|

Post by Jim on Jun 27, 2017 7:06:08 GMT

Still disagree Ron, down at Beech Hurst we are on the go the whole time but never has this been an issue, like I said its more of an indicator the tank is full than an overfull to stop it coming over your lap! Either way, Chop chop Jim we want to see her in steam  I'm trying hard Adam I really am but you know how it is. Get out to workshop then get distracted between doing overflow pipe, or maybe the drain plug then the pipe work for the water valves pop into ones mind and before you can say 'Bob's your uncle' it's morning tea time.  Jim |

|

|

|

Post by menachem on Jun 27, 2017 7:36:07 GMT

I'm just curious why overflow pipe is needed?

|

|

|

|

Post by Jim on Jun 27, 2017 7:42:31 GMT

Hi Menachem I certainly have completed the expansion links but that was way back. Basically the loco is ready to steam except I haven't completed the tender so can't supply water to the injectors...well I could jury rig something but I'd prefer to do it properly and given the tender is almost finished that may be fairly soon..No promises though.  Jim |

|

|

|

Post by Deleted on Jun 27, 2017 13:22:46 GMT

Still disagree Ron, down at Beech Hurst we are on the go the whole time but never has this been an issue, like I said its more of an indicator the tank is full than an overfull to stop it coming over your lap! Hi Adam Point taken, but there are two issues here. Would an overflow pipe prevent an overflow of the tank? Not if you leave a high pressure hose running, due to the different flow rates (unless the overflow is of sufficient bore - think of a kitchen sink with 15mm feed and 40mm waste). Would an overflow pipe give an early warning that the tank is nearly full? Undoubtedly yes, especially if you're using a tap that isn't directly by the engine, so it could be handy in that respect. You would still need to react quickly to avoid an overflow, unless the feed is restricted. I do like Bob's idea of the overflow discharging down the water scoop. The pipework would in fact be similar to the full size arrangement, except that the top of the pipe would be set a little lower under the dome. Try it Bob, and see how it works! Ron |

|

|

|

Post by Jim on Jun 28, 2017 4:08:11 GMT

The overflow pipe is now in place along with the drain plug with its extended handle. I chose a screw in plug as it let me utilize some surplus parts I had, besides saving time making something much the same. The next job will be to make the two 1/4 turn water valves for the injectors along with their water filters.  Jim. |

|