jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Jan 9, 2021 0:57:39 GMT

Unless I am very much mistaken, Dave's Bluebell pic appears to be a standard Gresham and Craven combination injector widely used pre- grouping days.

A variant might have been used post Stroudley on the LBSCR. It was a popular injector and made in different sizes and configurations... but we are getting slightly off topic!

Ed, your later Fenchurch miniature has Ashford injectors fitted - who made them and to what patented design I have no details. I would not be surprised if they were a non combination variant of the above by G & C. Post Stroudley, and quite a bit later, the Terriers had vertical injectors fitted. They would have been commercial off the shelf jobs - the LBSR didn't make their own. It is well documented that Ashford injectors of too large a size were later substituted on the BR survivors.

Apologies to Roger for the thread drift!

|

|

|

|

Post by Roger on Jan 9, 2021 9:26:18 GMT

I really don't mind these slight diversions, they are technically revealing as well as interesting. Although I've got a pretty good handle on how these things work and why certain design features are like they are, it's interesting to see what you can get away with when it comes to the geometry and overflows in particular.

|

|

|

|

Post by terrier060 on Jan 9, 2021 10:09:54 GMT

Unless I am very much mistaken, Dave's Bluebell pic appears to be a standard Gresham and Craven combination injector widely used pre- grouping days. A variant might have been used post Stroudley on the LBSCR. It was a popular injector and made in different sizes and configurations... but we are getting slightly off topic! Ed, your later Fenchurch miniature has Ashford injectors fitted - who made them and to what patented design I have no details. I would not be surprised if they were a non combination variant of the above by G & C. Post Stroudley, and quite a bit later, the Terriers had vertical injectors fitted. They would have been commercial off the shelf jobs - the LBSR didn't make their own. It is well documented that Ashford injectors of too large a size were later substituted on the BR survivors. Apologies to Roger for the thread drift! I will continue this on my Terrier thread Julian - please have a look and see if you can put me straight on this. Ed |

|

|

|

Post by Roger on Jan 9, 2021 20:44:09 GMT

Ok, this isn't going to work, but it was worth a try. The problem is that it's just too slender to resist the cutting forces. I had thought about that, but didn't think it would be as extreme as it is. I had thoughts of making a support in the tailstock, but to be honest, I think that would deflect too much too. So It's time to take Wilf's suggestion of doing it using the Mill as a CNC Lathe. I think I'm going to need at least ten cones, possibly twenty, to try all the different things I've got in mind, so I'll bite the bullet and do it that way instead. The support on the top of the Form tool is to stop the part climbing up over the tool.  20210109_202112 20210109_202112 by Roger Froud, on Flickr |

|

|

|

Post by andyhigham on Jan 9, 2021 21:46:14 GMT

I can foresee a future project will be converting the lathe to CNC

|

|

|

|

Post by Roger on Jan 9, 2021 23:32:02 GMT

I can foresee a future project will be converting the lathe to CNC It's somethiing I considered for some time, but concluded that it's of little benefit. The issue is tool changes and drilling. Although I've got a quick change toolpost and I could potentially set up different tools, they would have to be changed manually. Ok, that's not a huge deal, but as soon as you move the tool post, the settings are out the window. I suppose you could figure out a way to get the toolpost into a known position, and then the tools would come back to their set positions but it's not a trivial problem. Drilling would need to be done using tools mounted on the cross slide to make it automatic in any sense of the word. So personally, I don't think the benefit of it is that great since it takes pretty much the same amount of setting up as the Mill solution, but doens't have the benefit of tool change. So although this can be done, you have to ask yourself how much effort it is to set up and how often would you use it? I concluded that it was much more useful to do these things on the CNC Mill with a tooling plate that can be left set up. The tooling plate is located on dowels, so once you clock around the reference one and set that to Zero, all of the rest of the tools will be very close to the right positions. The benefit is that it's effectively auto toolchange. The downside is that the chuck or collet restricts what you can hold in terms of length. It means that it's wasteful on material. The biggest problem I have with the CNC Mill is creating the tool path because I've only got the Mill CAM module. If I eventually switch over to Fusion360, that will make creating the tool paths simpler. However, learning it is too time consuming for just this one job. One day I'll probably take the plunge. I know it's going to be pretty similar in many ways, but it's still not going to be a quick process changing over. |

|

|

|

Post by Roger on Jan 10, 2021 23:28:37 GMT

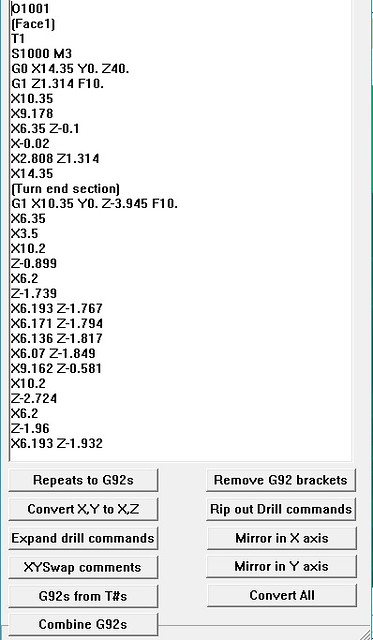

I thought I'd dig deep and do battle with Fusion360 today, to see if I can both model the One Piece Cone and generate an output for the Mill as a Lathe. Some of the sketch drawing seems unnecessarily awkward, with the system adding unwanted lines projected from the surface you're drawing on. I'm not sure whether you're supposed to leave them and live with the selection issues when you extrude the sketch or just delete them. It would be better if they left them off. Anyway, I scrapped and started again on this about six times before I was happy that I'd got the gist of how the sketching and extruding works and how you can modify the selections and edit the sketches retrospectively. I'm sure knowing another system inside out doesn't help. So this is the Lathe module with the five machining operations listed on the left under Setup. The bottom is faced off first, then I discovered that the strategy it used for machining the grooves roughed out the middle section before doing the grooves near the end where there's more overhang. The chuck is at the top of this picture by the way. So going back into the Grooving operation, I found that you can move a couple of sliders that define what section of the model it's allowed to machine. That meant I could make a copy of the original grooving operation and restrict one of them to the part furthest from the chuck, and then get it to finish the rest. Those are the 'Turn end section' and 'Turn back section' operations in the list. This is a screen shot of the simulation, paused part way through. I've actually got a video of it, but Flickr says it's uploaded it, but it's lying. It may be there isn't enough room in my allocation which is almost full. Fusion360 is more comprehensive than Alibre, and there are plenty of controls to allow me to insist that the bulk of this is machined without big sideways cuts. It's mostly done with plunges, just cleaning up with the finishing pass.  One piece cone CNC machining One piece cone CNC machining by Roger Froud, on Flickr The last two operations spot the end 1.5mm deep with a 1.2mm drill and then peck to 16mm with the #74 drill. I then did battle with the Post Processor to get a usable output. There aren't many Lathe post processors, so I had to pick a Siemens one. The Mach3 one is only for a Mill and it didn't like the turning commands. Anyway, as usual, these outputs run at the mouth, with crazy amounts of comment, blank lines, numbered blocks and setup commands that make it difficult to read. The commands mostly set things to a known state, but I'm never going to need any of that. So I've had a good look at what it's output and then gong through the post processor script and commented out all the junk I don't want. I've also enabled the Y-axis output which was commented out. I presume they have much the same script for the Siemens milling machines. Of course on a Lathe there is no Y-axis, only X which is the cross slide and Z which is the carriage or tailstock direction. On my mill, I need the Y-axis to be output as zero because I've got a utility program that uses the T# in the program to add the X/Y/Z offset for each tool. Unfortunately, Fusion360 won't allow multiple tools to be output in one program any more with the free version which is a nuisance. However, it does allow you to select all of the operations that use the same tool and output those as one chunk of G-code. I'll just have to merge the drill parts separatelty in a text editor. There's still a fair bit of playing around to get this to work, but it's potentially much easier to create tool paths this way compared to the knife and fork method I've had to use to date. I've ordered some 1/4" Brass rod for these so there's a small amount to clean up to get to the 6mm finished size. That will be a few days away, so I'm not sure what I'm going to do in the meantime. We'll see. I won't be idle, whatever happens! |

|

|

|

Post by lankyyorky on Jan 11, 2021 2:10:24 GMT

The biggest problem I have with the CNC Mill is creating the tool path because I've only got the Mill CAM module. If I eventually switch over to Fusion360, that will make creating the tool paths simpler. However, learning it is too time consuming for just this one job. One day I'll probably take the plunge. I know it's going to be pretty similar in many ways, but it's still not going to be a quick process changing over. Hi Roger,I don't know if it's of any help but are you aware of Vectric products?, I use Cut 2D for most profile cutting jobs in sheet material and find it very easy to use, they also do full 3D programmes (Aspire) but the cost is considerably more.https://www.vectric.comDave |

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Jan 11, 2021 3:16:29 GMT

Lovely way of Blowing your own Trumpet Roger! Several my get this link with current turning on the mill.

Yes I have used a Knife and Fork on a lathe.

The knife tool and strangely Fork for catching small bits being parted off.

The fork is also great for searching through swarf to find the perfect bit just vanished into it.

David, and Lily who usually volunteers to undertake the search.

|

|

|

|

Post by David on Jan 11, 2021 5:20:26 GMT

While reading your post I was wondering if you'd dig into the post-processor... and there it is :)

It isn't difficult to write a Python script to call the F360 API to gather all the ops in a setup and post-process them. I was some way down that track until I decided I didn't care about having all the tools in one program for the one-off jobs I do. Then in your code that stitches those fragments together you could emit the necessary moves to get the next tool in position. You can look in the script mentioned on a thread in the CNC section for an idea of how to do it, but that script is pretty messy - it can be done with much cleaner code. I was baffled by his code to determine a safe Z height for restoring rapids, or why he chose to post-process every op in every setup.

You can even do some debugging of the post-processor and plug-in scripts you create if you follow instructions on the Autodesk site. You do need to use Visual Studio Code for this, but I think it's worth the small amount of effort to install and learn what you need.

You could try the Tormach turning post-processor. I don't think there is anything weird enough about the RapidTurn that it would put out g-code that needed much tweaking. I admit I haven't looked at it though, and it wouldn't do your tool positioning.

I'd think twice about getting into F360 given Autodesk is almost certain to keep cutting features as people work around the existing hobbles, unless you make enough from it to pay for it.

I think you can project only parts of bodies, or select full bodies. Were you projecting whole bodies to get those unwanted lines in the sketch? If you can select and delete the things you don't want it's probably ok except I expect it would break the link to the body geometry so the sketch won't update. There is also an intersection operation, as opposed to projection. That would just get the outline of the body where it crosses the sketch plane.

|

|

|

|

Post by Roger on Jan 11, 2021 9:55:03 GMT

The biggest problem I have with the CNC Mill is creating the tool path because I've only got the Mill CAM module. If I eventually switch over to Fusion360, that will make creating the tool paths simpler. However, learning it is too time consuming for just this one job. One day I'll probably take the plunge. I know it's going to be pretty similar in many ways, but it's still not going to be a quick process changing over. Hi Roger,I don't know if it's of any help but are you aware of Vectric products?, I use Cut 2D for most profile cutting jobs in sheet material and find it very easy to use, they also do full 3D programmes (Aspire) but the cost is considerably more.https://www.vectric.comDave Hi Dave, I didn't know they also did a 3D product, so that's good to know. |

|

|

|

Post by Roger on Jan 11, 2021 10:18:47 GMT

While reading your post I was wondering if you'd dig into the post-processor... and there it is  It isn't difficult to write a Python script to call the F360 API to gather all the ops in a setup and post-process them. I was some way down that track until I decided I didn't care about having all the tools in one program for the one-off jobs I do. Then in your code that stitches those fragments together you could emit the necessary moves to get the next tool in position. You can look in the script mentioned on a thread in the CNC section for an idea of how to do it, but that script is pretty messy - it can be done with much cleaner code. I was baffled by his code to determine a safe Z height for restoring rapids, or why he chose to post-process every op in every setup. You can even do some debugging of the post-processor and plug-in scripts you create if you follow instructions on the Autodesk site. You do need to use Visual Studio Code for this, but I think it's worth the small amount of effort to install and learn what you need. You could try the Tormach turning post-processor. I don't think there is anything weird enough about the RapidTurn that it would put out g-code that needed much tweaking. I admit I haven't looked at it though, and it wouldn't do your tool positioning. I'd think twice about getting into F360 given Autodesk is almost certain to keep cutting features as people work around the existing hobbles, unless you make enough from it to pay for it. I think you can project only parts of bodies, or select full bodies. Were you projecting whole bodies to get those unwanted lines in the sketch? If you can select and delete the things you don't want it's probably ok except I expect it would break the link to the body geometry so the sketch won't update. There is also an intersection operation, as opposed to projection. That would just get the outline of the body where it crosses the sketch plane. Hi David, That's certainly interesting about calling the API, but I don't think it will come to that. Fortunately the post processor script can be butchered without much understanding since I'm really only interested in simple moves and the drilling functions. I think I've gone far enough down that road to make it usable when I merge the different tools together. I won't bother to do that until each tool has been trialled. I've got a utility program written in RAD Studion which is basically the old Borland Delphi or Visual Pascal. Every G-Code I create is made as a .cnc file which is immediately opened in my utility. It's pretty crude, but it allows me to do the following operations... Convert a comment of my definition to an array of outputs in X and Y at any offset so I can machine a panel of identical parts. Converts X/Y to X/Z with other modifications so a profile in Alibre can be used for turning on the mill Create G92 offsets from a text file that cross references the Tool Number with the X/Y/Z of each tool tip. Merge/expand the G92 offsets to create an absolute set of coordinates for each tool Rip out Drill commands so you're just left with the X/Y locations so I can drill them with the quill by hand. Mirror the program in X or Y The program was written initially to compensate for the fact that the CNC control I used to have was very basic and didn't do any of the canned cycles. It was expanded to let me do the other things as the need arose. It's proven to be very useful over the years. I'm only going to use Fusion360 for things like this where it's a pain to do with a Mill only output. Milling strategies don't translate to Lathe strategies so you have to define every tool path which is very time consuming and error prone. This ought to make that process much easier. I'd happily pay for Fusion360 to use it commercially, I could easily justify that just on the little I do. I wasn't projecting anything to get those extra lines. First create a sketch circle then extrude it to be a cylinder. Then touch the top, right click and create a new sketch. Immediately, it's created a circle sketch line that's projected from the original cylinder, although it's not obvious. If you then sketch a smaller circle, you'll find that you can hightlight two areas on the top of the cylinder when you go to extrude it again. I found this very confusing and unnecessary. I can't see that it helps with creating the model. |

|

jasonb

Elder Statesman

Posts: 1,246

|

Post by jasonb on Jan 11, 2021 17:09:36 GMT

Roger, you could have saved yourself a lot of time if you had simply exported the part from your Alibre model as a STEP file and opened that in F360 rather than try and draw it again in an infamiliar program. That's what I do and it only takes a few seconds. You can alter the imported file in F360 if you need to.

Whatever you use Alibre or F360 I would not do it as a stack of extruded circles, just draw a half profile and revolve 360deg about a central axis.

|

|

jasonb

Elder Statesman

Posts: 1,246

|

Post by jasonb on Jan 11, 2021 17:13:52 GMT

Deleted meant to edit above

|

|

|

|

Post by Roger on Jan 11, 2021 19:43:54 GMT

Roger, you could have saved yourself a lot of time if you had simply exported the part from your Alibre model as a STEP file and opened that in F360 rather than try and draw it again in an infamiliar program. That's what I do and it only takes a few seconds. You can alter the imported file in F360 if you need to. Whatever you use Alibre or F360 I would not do it as a stack of extruded circles, just draw a half profile and revolve 360deg about a central axis. Hi Jason, You're quite right of course, but I wanted to make a start at getting to grips with Fusion360 as I think it's what I'll ultimately end up using. I use both methods to creating these shapes. Sometimes it's more convenient to do it one way rather than the other. The whole arrangement of the injector cone design was done like you suggest so that I could use equations to drive the geometry. That would be next to impossible with a stacked construction. For most things I prefer to create the shapes as a stack, with things like O-ring grooves constrained to each other. Things like Hexagons can be easily added that way as they're formed in the same way as a stack. I don't think there's a right or wrong way to do these things. I've created O-ring grooves as part of the structure, added them as swept cuts or annular extruded cuts from a plane. There are pros and cons for each method. When you're up to speed with a CAD package, they all take about the same time. |

|

|

|

Post by David on Jan 12, 2021 10:53:55 GMT

Your program sounds very useful. Is it a g-code interpreter or just pattern matching and replace?

How do you put the comments in? I know F360 has some manual g-code thing which I tried to use while I was mucking about with my post-processor/API scripts. The F360 post-processor structure is pretty simple, it was the work of less than a day to add a new property and figure out how to restore a lot of rapids based upon the current Z height. I'm still missing rapids that happen below the top of the stock but outside the stock X/Y boundaries but they happen in toolpaths I don't use much anyway.

F360 has built in support for duplicating a set of ops in an X/Y pattern to make a panel of parts. I would not be surprised if that disappears from the free version this year. I sometimes use it when I'm doing a row of axleboxes. Other times it's easier to just draw a bunch of lines and use the trace toolpath - that's a very useful one to fall back on when you want a really simple toolpath but all the other options over-complicate matters.

Drilling with the quill by hand would be nice sometimes but is out for me, obv!

I guess if you select the face of a body as the sketch plane it puts the edges of the body in the sketch. I must have done that many times and been satisfied with the behaviour because it's never struck me as a problem or even stood out as weird. I like being able to reference the geometry of the face in my sketch - the centre and circumference of circles, or edge lines.

I don't think you can reference parts of other sketches while you're editing one. That would be the alternative for the way I often work, wanting to reference the face I'm building onto. Or just put everything at the origin, which I also sometimes do when a lot of circles are involved.

|

|

|

|

Post by Roger on Jan 12, 2021 18:10:54 GMT

Your program sounds very useful. Is it a g-code interpreter or just pattern matching and replace? How do you put the comments in? I know F360 has some manual g-code thing which I tried to use while I was mucking about with my post-processor/API scripts. The F360 post-processor structure is pretty simple, it was the work of less than a day to add a new property and figure out how to restore a lot of rapids based upon the current Z height. I'm still missing rapids that happen below the top of the stock but outside the stock X/Y boundaries but they happen in toolpaths I don't use much anyway. F360 has built in support for duplicating a set of ops in an X/Y pattern to make a panel of parts. I would not be surprised if that disappears from the free version this year. I sometimes use it when I'm doing a row of axleboxes. Other times it's easier to just draw a bunch of lines and use the trace toolpath - that's a very useful one to fall back on when you want a really simple toolpath but all the other options over-complicate matters. Drilling with the quill by hand would be nice sometimes but is out for me, obv! I guess if you select the face of a body as the sketch plane it puts the edges of the body in the sketch. I must have done that many times and been satisfied with the behaviour because it's never struck me as a problem or even stood out as weird. I like being able to reference the geometry of the face in my sketch - the centre and circumference of circles, or edge lines. I don't think you can reference parts of other sketches while you're editing one. That would be the alternative for the way I often work, wanting to reference the face I'm building onto. Or just put everything at the origin, which I also sometimes do when a lot of circles are involved. It's a crude string replacement program, nothing clever at all. I can add comments to Alibre CAM by including them as part of the name of the operation. I've just modified the Haas turning Post Processor instead of the Siemens one because it's more true to the simple G-Code list supported by Mach4. Siemens format things like Peck drilling in their own way, with brackets and comma separated values. It outputs all kinds of junk that I don't want, some of which Mach4 won't recognise anyway, so I've carefully tracked each of those down and now have a really nice clean output and I can actually see what's going on! There's actually a check box in the Preferences to be able to turn off Projecting profile to the new sketch, so I've done that. There are projection tools in the menu to allow you to selectively project from other sketches, so it's not a problem when you want to do that. If you google 'fusion360 projecting sketches' you'll find several YouTube tutorials on how to do that. |

|

|

|

Post by Roger on Jan 12, 2021 18:28:09 GMT

I use these Cup wheels to grind special tools. The Jones & Shipman style of mini tilting swivel vice is really useful for this sort of thing. Here I've tipped the handle end of the vice down about 3 degrees, set by eye from a vernier protractor while holding a long piece of HSS stock in the vice. I'm not adding any side clearance front to back on the tool ie it's parallel when looking from the top. The grooves are pretty shallow so it shouldn't be a problem.  20210112_105501 20210112_105501 by Roger Froud, on Flickr I've already tickled the side facing the camera while it was on the other side of the vice, you can see the shiny ground surface. I roughly ground a fair bit of the shape on the off hand grinder to save the Cup wheel. I've ground this almost to the width, then dressed the wheel for the final couple of cuts.  20210112_105426 20210112_105426 by Roger Froud, on Flickr The vice was then set level by clocking a block held in the vice, and the tool was tipped up at a bit of an angle for the front clearance. I just set that by eye.  20210112_111009 20210112_111009 by Roger Froud, on Flickr I touched the top with my diamond lap and did the same on the corners just to take the razor edge off. I also turned down a piece of Brass rod and drilled a hole 6mm deep with the drill it needs to hold. That was cleaned with Acetone and then Loctited in place. That leaves 18mm protruding and I only need 16. I've got ER32 collect chucks on the tooling plate I use for Turning on the Mill, but there's no way to hold the small drill directly in the collet. I could have used one of my Pin Chucks, but even the Eclipse one is rubbish when it comes to runout. The end will only be spotted to 1.2mm diameter, so the drill needs to pick that up else it's going to snap it straight off.  20210112_145409 20210112_145409 by Roger Froud, on Flickr Anyway, I've had another go at modifying a different Post Processor (Hass turning) because that's closer to what Mach4 needs when it comes to the Drilling Canned Cycles. I've hacked out loads of junk I don't need, so it's a nice clean output now that I'm sure I can use. I intend to give this a dry run in fresh air shortly just to make sure it's all plausible with no nasty unexpected movements before I try to set the tools up. The Brass 1/4" bar is on its way, with a projected delivery on Saturday, so that's not too bad. |

|

|

|

Post by Roger on Jan 13, 2021 15:58:29 GMT

Ok, I'm gradually limbering up to makine the One Piece Cone on the Mill. This is my trusty Lathe tool plate which locates on the two dowels at the back. The RH one of these is always 0,0 and the bed surface is Z0. Here I'm clocking the dowel with the knee at the top and the quill retracted and locked. This gives me a repeatable position to use if I take the tooling plate off and then want to run the program again. The plate is a slab of Plough Ground Steel, ordered specially for the purpose. It's held down with two M12 Cap Screws using T nuts. There are more places for bolts, but I never use them. There are places for three turning tools in a staircase arrangement with packing pieces so I can accommodate jobs up to about 80mm long. This was all conceived to enable me to make the Bugle and Trombone mouthpieces way back in 2013. I made over 100 of those in the end. Here's a link to that process in case you haven't seen it. The rear turning tool is usually a stout parting tool which is set high so it can reach the back of the job. Here you can see the grooving tool in the front tool position which is T1, it's stood out a long way so the chuck doesn't foul the tool post behind it. The centre drill is a 1.2mm PCB drill with the blue collar and that's T4, while the next one along it T5 and that's the #74 slow helix drill for Brass. The tool heights are set using a height gauge resting on the flat base.  20210113_134157 20210113_134157 by Roger Froud, on Flickr The tool offsets are entered into this text file which has handy reminders of how to change the offsets when you're trying to get the diameters or bores right. It's not very intuitive, so it's easy to make a mistake and go the wrong way. This file is used when the CNC utility program option 'G92s from T#s' is chosen. Note:- Most of this file doesn't do anything. Everthing in (these brackets) is ignored.  ToolOffsetFile ToolOffsetFile by Roger Froud, on Flickr The initial offset for the turning tool is obtained using the wobbler on the front of the tool for the Y offset, then subtracting the ball radius from the offset on the DRO  20210113_142748 20210113_142748 by Roger Froud, on Flickr Now we know the edge of the tool, we can move to that and find the end. This time the ball radius is added to the DRO reading.  20210113_141251 20210113_141251 by Roger Froud, on Flickr I've then driven to the X/Y figure in the ToolOffsetFile.txt as a sanity check to make sure I've not gone the wrong way. This looks plausible.  20210113_142659 20210113_142659 by Roger Froud, on Flickr I've had to go back and modify the Post Processor script in Fusion360 because they output huge comments telling me what restrictions are there on the non commercial version. That's all very well, but Mach4 thinks they are separate blocks and then complains that they don't have closing comments. So I've found the function in the script that outputs the comments, and just don't output them if they are more than 30 characters long. You can see that my own comments are still there, but the others aren't. Anyway, this is the start of the turning section of the program, and you can see that it's pretty clean. CAM outputs are horrendous and unnecessarily complicated for our purposes, so I prefer to cull the junk I don't need. This is the raw output from Fusion360 inside my CNC Utility program...  Raw CNC output Raw CNC output by Roger Froud, on Flickr ... and this is how it looks after pressing the G92s from T#s button. You can see that it's added a comment to the top to say what's changed, and it's added the G92XYZ line which is the value I put in the ToolOffsetFile.txt (Edit:- I've just single stepped this and scratched my head as to why it faced off to the centre, then completed the rest without touching the outside at all! The penny finally dropped when I realised that the Lathe outputs refer to the X values as diameters, and of course, I'm treating them as radii. So, it's back to the post processor to tell it to use Radius mode instead) I'm sure most people would use it just as it is, but I think it's dangerous. If you interrupt the program between tools, you can get in a muddle about what tool offset is active and end up with a crash.  CNC output with tool offsets looked up CNC output with tool offsets looked up by Roger Froud, on Flickr So I use the 'Combine G92s' button which just goes through the whole file adding the offsets to every occurrence of X, Y or Z.  CNC output with combined offsets CNC output with combined offsets by Roger Froud, on Flickr That approach works for simple programs, but it isn't subtle enough for this program which uses a canned cycle for the drilling. You can't blindly add the offset to the Z-1.6 in the G81 block because it's the depth of the hole, NOT the absolute position!  Raw CNC centre drill Raw CNC centre drill by Roger Froud, on Flickr So I've had to revisit the CNC Utility program and make sure it excludes the Z value in all of the G81 and similar canned cycles that do the same thing. I haven't come across this before because I've never used canned cycles on the mill. I've got a utility that expands these which I've used to date because historically my old controller couldn't interpret them. So, it's about time this was sorted out so I can use these commands. You can see that I've done both steps on this converted file, and the G81 retains Z-1.6 whereas the other have acquired their necessary offsets.  CNC centre drill with combined offsets CNC centre drill with combined offsets by Roger Froud, on Flickr So the result of all this is I end up with an program with absolute coordinates for every tool which means I can single step through a program and be sure of what's going to happen next. You have to be very cautious when setting up this kind of program, because crashes are a moment's inattention away. Once it's set up, you can just walk away though. Using Fusion360s Lathe output is a huge help with this though, because they have controls for safe moves and you can see visually what's happening with the tool path and simulations. |

|

|

|

Post by David on Jan 14, 2021 3:06:47 GMT

So I've found the function in the script that outputs the comments, and just don't output them if they are more than 30 characters long. You're ahead of me, that was my first question. It was frustrating I couldn't find a way via the F360 API to get access to the actual toolpath operations. You can bring them up in the UI, and they have the rapid moves intact at that stage and having access to that information would have been useful. But I also wanted to remove annoying comments from Autodesk and add my own. A piece of gound steel that size wouldn't be cheap. Mouthpieces must pay well! |

|