|

|

Post by jordanleeds on Dec 26, 2013 20:32:00 GMT

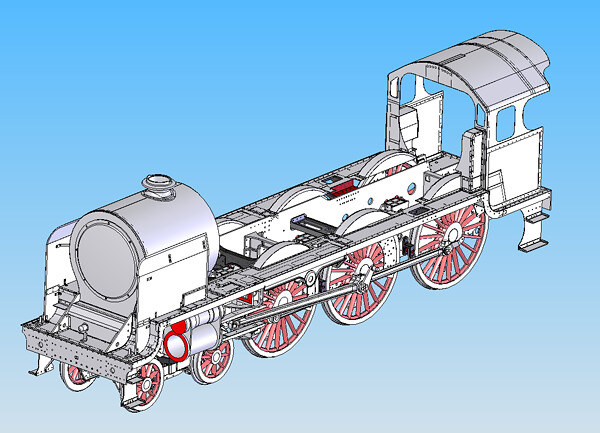

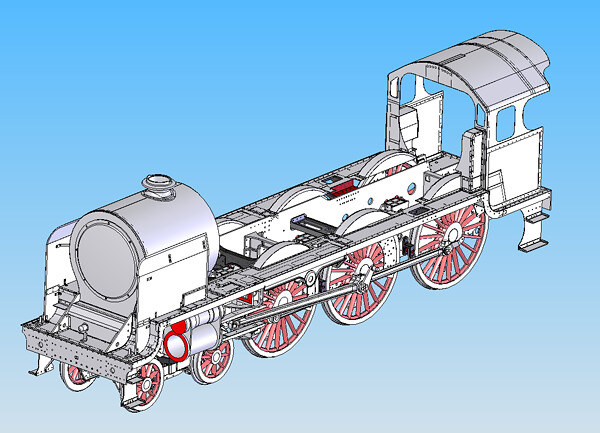

Not having seen much mention of this project on here I felt it apropriate to start a detailed thread to keep you all up to date with the Constriction of the LMS Patriot 4-6-0 "THE UNKNOWN WARRIOR"

The 3 cylinder LMS Patriot class was introduced towards the end of Sir Henry Fowler's reign as CME of the LMS, a position he held from 1925 until 1932 when William Stanier was appointed in his stead.

Publicly the class was presented as a rebuild of Bowen-Cook’s large boilered Claughton 4-6-0 and the first two were produced from the remains of two Claughtons badly damaged in accidents. There is some dispute as to how much original material was re-used but it would not amounted to much more than driving wheels, bogies and some standard fittings.

In fact the Patriots as they were known after 1937 were a small boilered version of the Royal Scot, utilising a very similar chassis combined with the Derby designed G9 ½”S boiler utilised on the rebuilt Claughtons.

After the first two were produced the pretence that they were rebuilds disappeared (though they did replace an equivalent number of Claughtons) as only the 6’3” bogies were reused. The last ten to be built (nos 5542 to 5551) were regarded as new builds.

Technically the class had three 18” x 26” cylinders (identical to the Scots), 6’9” driving wheels mated to a boiler pressed to 200lbs. Originally intended to number 57 units the last five were built with Taper boilers and became the first of the Jubilees.

All the Patriots were painted out in LMS crimson lake livery with pale yellow and black lining when first built and carried 'LMS' lettering on the tenders. From 1946 most were painted out in LMS lined black with straw and maroon lining. Some Patriots kept this style of livery in very early BR days with the name British Railways written in full on the tender. All of the class were later painted out in British Railways standard express passenger green with orange and black lining with the BR 'lion and wheel' logo or later BR crest on the tender.

The class, often referred to as 'Baby Scots', were an immediate success (unlike the Jubilees), displaying consistently good performance, marred only by the tendency of the wrapper smoke box to draw air after high mileages. With the exception of 45508 (hideous stovepipe chimney and the 18 rebuilt with the 2A boiler) no major alterations were attempted and the class was withdrawn over a two year period between 1960 and 1962 having all covered around 1.3 million miles each, unfortunately too early to be considered for preservation. The last two withdrawn (45543 and 45550) were in good condition on withdrawal.

Unfortunately all were scrapped.

To Be continued ...

|

|

|

|

Post by jordanleeds on Dec 26, 2013 20:44:16 GMT

Now that is the History lesson over with we have now commenced building the locomotive and progress has been focused on completing the frames & Wheels. Most notably has been the use of polystyrene patterns for the Inside cylinder and this method will be used for casting the two outside cylinders in the new year.  The Unknown Warrior 2013/14 The Unknown Warrior 2013/14 by jordan leeds photography, on Flickr  1401476_453654974754894_1774225089_o 1401476_453654974754894_1774225089_o by jordan leeds photography, on Flickr Work by volunteers for 2014 is to be centred around the lubrication system and the many runs of pipework that are required including conduit runs for the required equipment for mainline operation.  45551_Warley_24-11-13_10222 45551_Warley_24-11-13_10222 by jordan leeds photography, on Flickr We recently displayed the Partially completed locomotive at the National Model Railway Show at the NEC where it was Very well received and several new volunteers joined our small but dedicated ranks. I would be Very interested to hear from anybody whom wishes to get involved and help bring The Unknown Warrior one step closer to steaming in 2018 as part of the WW1 Armistice commemorations Jordan Leeds LMS Patriot Project Volunteer Liaison Officer www.lms-patriot.org.uk |

|

|

|

Post by dinmoremanor on Dec 26, 2013 22:25:38 GMT

With more generous allowances for shrinkage being employed for the construction of the outside cylinders hopefully....!! Was good to see it at the NEC.

|

|

|

|

Post by greenbat on Dec 27, 2013 10:41:10 GMT

With more generous allowances for shrinkage being employed for the construction of the outside cylinders hopefully....!! Was good to see it at the NEC. Oh dear, what happened there? I recently heard a tale, I think it was the clan project, who had to scrap their first set of frames. They'd not got the paperwork for the steel, so couldn't prove it was up to main line running... |

|

|

|

Post by jordanleeds on Dec 28, 2013 15:40:26 GMT

In short the Cylinder casting was found to be unfit for use as the casting had cooled too quickly which caused the main bore to oval. A New cylinder is already in stock and will be machined in the new year ready for fitting to the locomotive, The Two outside cylinders will be cast in February/march and will use the polystyrene pattern method with a slightly differing chemical composition of material

|

|

|

|

Post by Deleted on Dec 28, 2013 18:39:56 GMT

Just as a matter of "Trading Curiosity"....what will happen regarding the U/S casting now ??....If it was sold to you by a professional foundry and, presumably purchased within modern trading circumstances, then is there a case for it to be returned as "Unfit for purpose" and a reclaim of some monies (time spent preparing etc. )or is this a case of "They can do that Sir".....with only a replacement casting being supplied ??

|

|

|

|

Post by Deleted on Dec 28, 2013 21:37:59 GMT

The Two outside cylinders will be cast in February/march ............with a slightly differing chemical composition of material. Just out of curiosity, what grade of cast iron are you using? Is it S.G. (spheroidal graphite) iron? |

|

|

|

Post by jordanleeds on Dec 29, 2013 13:50:33 GMT

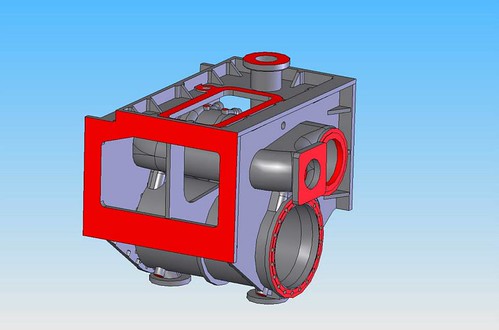

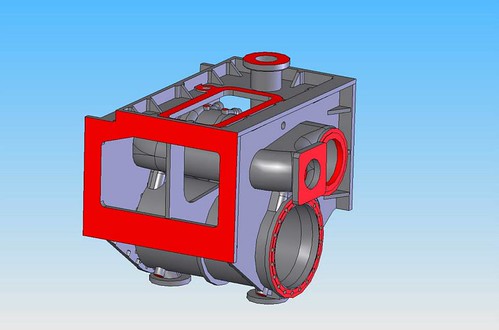

Just as a matter of "Trading Curiosity"....what will happen regarding the U/S casting now ??....If it was sold to you by a professional foundry and, presumably purchased within modern trading circumstances, then is there a case for it to be returned as "Unfit for purpose" and a reclaim of some monies (time spent preparing etc. )or is this a case of "They can do that Sir".....with only a replacement casting being supplied ?? Without putting too much sensitive information on this my understanding is the foundry has taken the casting back and as a gesture of goodwill provided the replacement to the updated specification as a cost neutral gesture of goodwill with a couple of provisos in place. SG Iron is being used and if i recall some adjustments to it have yielded better results this time around. This has been the first time that Polystyrene patterns have been used to produce a locomotive cylinder and it has provided us a very large learning curve but we now know how to do it and we estimate that it is the first Inside cylinder that has been cast for a LMS 3 cylinder engine in over 60 years. A CAD Model of the locomotive has been Built and individual components detailed  575381_590963474268725_577353543_n 575381_590963474268725_577353543_n The job is split into layers to ensure that each of the shapes within, for exhaust steam out etc, are exact. The poly layers are then stuck together By the pattern makers and will then be used as a single pattern to cast from. A traditional wooden pattern for this very complicated design would involve countless core boxes and months of work to create the same steam passages - also, the material cost for this is less than £100, which would not be the case with hard wood. Also, favourable in comparison is the timescale, it looks like the conversion of the original LMS drawing for CAD will result in a finished pattern in about four weeks -start to finish, so that means that the WHOLE job takes something like 7 weeks! - excluding machining.  904084_574588459239560_1275091753_o 904084_574588459239560_1275091753_o

The large object propped up at the rear of the table is one of the layers of the cylinder , coincidently the other patterns on the table are for the front bogie that will be constructed in 2014  478505_574588252572914_1530799178_o 478505_574588252572914_1530799178_o

Below is the completed pattern ready for shipping to the foundry  8899_590963570935382_739365534_n 8899_590963570935382_739365534_n The Pattern is placed in the sand boxes and the sand packed in place Leaving the Patten in the sand this then flashes off once the metal is poured and the cavity filled with SG Iron  977499_199996276817777_1341752860_o 977499_199996276817777_1341752860_o

With the pour complete the sand boxes where left approx five days before knocking out to allow for cooling  965112_588304967867909_1963637856_o 965112_588304967867909_1963637856_o

946567_590963940935345_1356835236_n 946567_590963940935345_1356835236_n by With the casting still hot five days later it is knocked out of the sand and prepared for grit blasting and inspection  1045083_606701356028270_423163501_n 1045083_606701356028270_423163501_n The first inside cylinder set up for machining in the black country! We endeavour where possible to use British industry to produce the components and have to this day done so with good success . there are a number of smaller fittings and parts that we are looking to produce that would be ideal for the home machinist or model engineer so if you would like to help please do get in touch! |

|

|

|

Post by Deleted on Dec 29, 2013 15:34:42 GMT

"Lost plastic" doesn't have the same ring to it as lost wax perhaps but the results speak for themselves !!!!----------I bet Fowler, Churchward, Stanier and Co. would have given BOTH arms for this sort of productivity ??.........Indeed, we do live in "exciting times"....Will it be possible to assemble a decent rake of coaches to match the loco when the time comes ??--------------Well done, lads-----------well done indeed !!

|

|

|

|

Post by alanstepney on Dec 29, 2013 16:18:47 GMT

That is one heck of a lump of casting!

I just hope that it turns out OK, and hasnt any blow holes or other imperfections, so that they can machine it without any problems.

|

|

|

|

Post by jordanleeds on Dec 29, 2013 18:48:13 GMT

2.78 tons of Casting to be precise and that's just the middle one! two more to follow, Blow holes and imperfections are hopefully okay

|

|

|

|

Post by drumkilbo on Dec 29, 2013 19:29:33 GMT

Amazing and fascinating stuff, thanks.

Ian

|

|

|

|

Post by donashton on Dec 29, 2013 20:40:54 GMT

The Patriot people are to be congratulated on some pioneering work, which frequently treads new ground at the risk of the odd problem. The tenacity and far-sightedness of volunteers, engaging British engineering (alive and updated)with items quite unfamiliar to them is courageous and to be applauded.

4709 stood next to The Unknown Warrior on the same road for many months, inducing some mild ribaldry about not letting the Patriot out until we were ready! We relented, of course. Well done.

Don.

|

|

|

|

Post by Deleted on Dec 29, 2013 21:21:38 GMT

I keep going back to have a look at that "machined" photo....Isn't that a lovely Bit'o Kit ??.....Are those grooves between the studs for a copper ring gasket seal ??....EDIT}---- Hang on, is that PETE WATERMAN wielding a needle gun in one of those photos  ? LoL |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 29, 2013 21:27:15 GMT

the above inside cylinder block is the scrapper. a set of frames scrapped too. not perhaps the best start to a big project, but i wish them well.

cheers,

julian

|

|

|

|

Post by jordanleeds on Dec 29, 2013 21:35:14 GMT

the above inside cylinder block is the scrapper. a set of frames scrapped too. not perhaps the best start to a big project, but i wish them well. cheers, julian In the interests of clarity The Images of the Inside cylinder block is for scrap We have not scrapped the frames and there have been no issues with the frames whatsoever You may not see this as the best start but it has not been done in over 70 years and certainly not been done using the methodology that we have chosen To Produce the timber pattern for the cylinder was quoted at £35k the above cylinder and its replacement has cost the project no more than £6.5k so in reality as i said it has been cost neautral |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 29, 2013 21:38:38 GMT

jordan,

are you sure the frames arent mark 2 and replacements? the original frames (mark 1) were found to be U/S. the Patriot website confirms same plus all the railway magazines.

cheers,

julian

|

|

|

|

Post by jordanleeds on Dec 29, 2013 21:48:55 GMT

I can confirm that We are on the original frame plates that where cut on the 31st of march 2009 And they have not been scrapped there have not been any issues with these at all

|

|

|

|

Post by Deleted on Dec 29, 2013 21:55:15 GMT

Was there not enough metal on this Mk1 block to put a liner in ??.. EDIT}--- If that's the scrapper it'd make a great Fowlerpot.....oops, that should read}---FLOWER POT in your front garden ??

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 29, 2013 22:10:15 GMT

apologies to jordan et al re the frames appears i have got mistaken with something else so many apologies.

i do wish this project every success. i remember seeing SCOTS GUARDSMAN in bits many years ago at tyseley many years ago. have since seen it running and a lovely loco. shame the ex-bressingham ROYAL SCOT isnt back in action yet.

cheers,

julian

|

|

? LoL

? LoL