|

|

Post by Doug on Feb 21, 2014 13:03:44 GMT

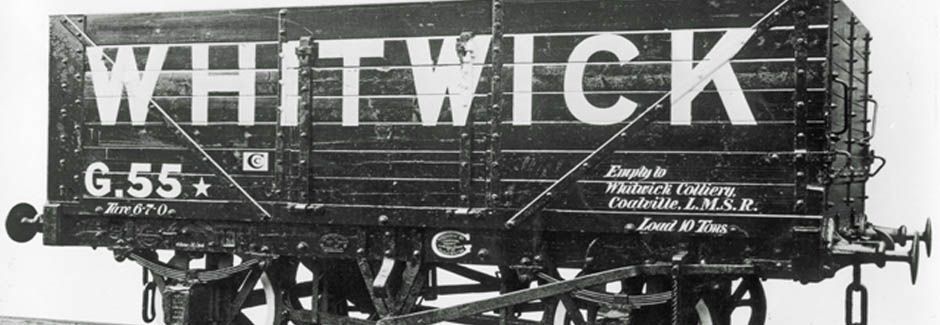

Hi guys I have had it in mind to build a Waggon for my train for some time however having been doing some driving lately I have discovered that it could be very handy indeed to have one for a coal tender. I want to build two of them for my two loco's Butch was built in the late 60's to early 70's by my great grandad he worked at Snibstion mine as a maintnence fitter so I thouhgt it fitting to have this paint on the wagon for that;  my loco that I am building "speedy" I want to put this behind it;  as that is the home of the model club and I work on the old colliery site so thought it was apropriate. Now I have started to draw up the plans for the chassis and from that bit upwards looks to be very easy indeed just a bit of woodwork and some simple strips of metal. The tough bit seems to be the running gear the cost of which is crazy so I want to make it myself if at all possible. Can anyone point me in the right direction as to the sizes of the metalwork for the axleboxes and brake links etc. I dont want to go too far off, on my own scale just incase I can get some cast parts like the axleboxes and dummy springs etc. any advise is most welcome. (I am not adverse to putting bearing blocks underneath etc.) thanks, Doug |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Feb 21, 2014 14:47:21 GMT

hi dug,

this info might also be of help to anyone else contemplating building their own 5"g wagon so i will describe what i did or how to vary things. in all this i have been greatly helped by the advice and help from fellow club member dai roberts who has built nearly 20 wagons and who inspired me to have a go at my own. what dia doesnt know about railway wagons isnt worth knowing!

1. research what you want to do first as despite the RCH clearing house standards (mainly 1909 and 1923) that were supposed to be adopted, there are lots of detailed variations

2. wheelsets. you can buy these ready made in all sorts of types (disc/correct 8 spokes/old fashioned double wrought iron strip spokes).

i used some old 10 spoke tender wheel castings i already had. axle material whatever bms steel dia you have to hand. it will need turning down to the correct diameters, and make sure you get the journals nice and well polished. disc wheels will work out cheapest and have the additional advantage of being heavier.

3. axleboxes. a huge variety in fullsize. i made mine out of brass round bar milled to quite a complicated profile, with separate covers added on which i etched myself. i have followed what i do with loco tenders and made the journals an easy fit and will get packed with grease and should require no further attention. obviously if you buy commercial lost wax castings then as they are usually 'white metal' then bearing material needs to be fitted to suit the wheelset journals.

4. 'W' irons. you can get laser parts but i cut mine out of 4mm BMS plate. the thickness plus outer face of the 'W irons' determines the slots in the axleboxes and the inner sides of the wagon chassis solebars, also how much you take off the front of the wheel hubs etc...

5. which leads us to the chassis. on a wooden chassis (which should be hardwood) there are 4 or 8 plates with threaded ends on the outer ends of the solebars. the threaded ends go through the headstocks. on lots of fullsize wagons the position of these threaded bars is crucial and also determine the width of the chassis together with 4. above, as quite often these threaded bars also form the fixings for the plates to which the buffer stocks are attached (this is certainly the case with my LBSCR wagon ive copied).

the 'W' irons also determine where the cross beams go, and the wheels determine where the lengthwise beams go. every part seems to have more than one function which are all inter-related! if you put one part in the wrong place it will clash with something else or you need to add other bits to make up one of the functions lost by the mis-placement! a lot of it on a wooden chassis is plain woodwork and design of wooden joints rather than anything to do with 'model engineering'.

note also the curb rails/outer solebars on a wooden chassis are rebated at their ends over the headstock, the amount above the rebate to top of the curb rails determines the level of the floor planking/the thickness of the floor planking determines the height of the curb rail.

6. if you dont like messing about with hundreds of 10BA fixings and 10BA nuts, then probably a wooden wagon isnt for you!

7. buffers and stocks - same as axleboxes - huge variety depending on whether RCH type or not. the older type buffers have incredibly thin spindles and large diameter (but thin) heads. i hacksawed some discs out of 1 1/4" steel bar for the heads then silver soldered the spindles on then turned to shape. my buffer stocks were turned from brass bar.

8. i dont really like dummy coiled springs for the axleboxes. mine are leaf springs. they not only look the part but i think provide far better suspension especially if the weight of the wagon changes a lot.

9. drawhooks and drawbar. unlike a loco tender the draw hooks are attached to a long bar that runs the whole length of the chassis, albeit split in the middle with springs or 'doughnuts' fitted in a steel cage. otherwise a wooden chassis would be pulled to pieces by the rear coupling! this also determines the position of the middle lengthwise beams. the plates on the headstocks behind the drawhooks look like they are bolted on - but are usually very long lengths of studed rod with nuts on the ends which are also a structural part of a wooden chassis and yet again determine the position of the middle lengthwise beams.

10. brakegear. far too long and complicated to describe here, and best to order some of the excellent wagon books from your local library. the 'V' hangers can be hacksawed from 3mm BMS plate. you wouldnt buy completed ready made brake gear for a loco tender so i personally see no reason why anyone would consider buying ready made brake gear for a wagon!

my personal view is that there is far more work involved in making a wagon than a loco tender! (especially as after having made the wagon you then have to make up a special container just like a tender body for the coal and water)

cheers,

julian

|

|

davidm

Seasoned Member

Posts: 109

|

Post by davidm on Feb 21, 2014 17:04:42 GMT

You could have a look at www.lightmoor.co.uk/category.php?§ion=CatPrivateOwner which is an extensive list of PO wagon publications. In the second paragraph of the web page there is mentioned an index (30 pages!)to those books that includes references to both of the PO companies that you're interested in. David |

|

|

|

Post by ejparrott on Feb 21, 2014 17:19:04 GMT

I think the first or second series of articles Doug Hewson did in EIM was the 7-plank mineral wagon. In his early articles he gave a lot of details, and you will find the information for the W and V irons there, and also all the RCH brake gear. Dave Noble also castings for wagon parts, I believe his axleboxes are whitemetal with a bronze bearing, but it's a while since I've looked.

If you're going to do it, you need to do it right, it's just not worth taking shortcuts and trying to re-invent the wheel. The NRM at York has got stacks of drawings of wagons, and they're worth looking at. You can either order copies of the drawings, or take a notebook and pencil and copy the drawings.

|

|

|

|

Post by Doug on Feb 21, 2014 18:13:09 GMT

Thanks guys I will get planning and have some serious CAD time on this one it looks like I need to find some 3.5" wheels from somewhere, I have found quite a few venders selling the solid wheels at £8-12 each so I will keep trawling ebay for a set of castings I think. Do you think it's possible to swap the top body and have just one chassis? It would save a whole load of cost and work if it was possible.

|

|

|

|

Post by ejparrott on Feb 22, 2014 8:29:58 GMT

The disc wheels on wagons are nothing like the disc wheels you can buy from various vendors. They have a curious form to the centre portion and three holes. The castings are readily available.

The RCH chassis is a fairly standard item, however it is fitted up as required for the indiviual wagon body type. For instance, the 7-plank end door mineral wagon body in 12T format has different buffers at each end, those at the door end having raised castings to stop the floor sliding out with the load when it's tipped up. The version without the end door has 4 identical buffers.

Have a look at Dave Noble's catalogue.

|

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Feb 23, 2014 21:34:38 GMT

Would these drawings help? Cheers David |

|

|

|

Post by ejparrott on Feb 24, 2014 7:22:12 GMT

They're good David, where did you find them?

|

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Feb 24, 2014 9:25:27 GMT

Hi Ed

From a book that is " . . . the only manual for craftsmen and apprentices engaged in the practical study of the industry. "Railway Wagon and Tank Construction and Repair" by F Ogden. Given to me by an old hand in Wagon Repairs Ltd (where I worked on coming over from Canada, we had bought the company), later to become Rail Car Services but now all gone. it is a proper text book. It tells you step by step on how to build a wagon by hand!

Cheers David

|

|

|

|

Post by Doug on Feb 24, 2014 12:31:48 GMT

Would these drawings help? Cheers David very much so thanks david  |

|

|

|

Post by sparticusrye on Feb 24, 2014 14:18:51 GMT

Those few pages will be very useful in the future.

|

|

|

|

Post by standardsteam on Feb 24, 2014 14:35:47 GMT

..and just a pendant note, the book refers to "Axleguards" not "W irons". ;-) On steel underframes, but not necessarily on wooden underframes, these have a joggle in them to bring the centre of the leaf spring under the solebar, whilst keeping the wheels in gauge. Note that axles have a taper to the centre (usually).

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Feb 24, 2014 16:14:27 GMT

david,

many thanks for posting those fascinating extracts from your book.

cheers,

julian

|

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Feb 24, 2014 18:48:39 GMT

Hi Julian

Thanks for your remarks. I will blame you for driving me off topic for a minor excursion. Earlier on I worked for Procor and we had a lease fleet in the UK. We then bought the Charles Roberts works in Horbury which was a total cock-up, that is why I was sent from Canada to Horbury. Later they wanted a repairing capability and we bought Wagon Repairs, a company in an even worst mess. I was dispatched to see what we should do.

One of our works was at Chesterfield which really only produced 13 plate springs in the belief that this would go on forever, the Brueninghaus spring was being adopted of course. As I walked around this massive derelict works I found a sign that said something like this,

“Any workman that failed to produce a proper sole bar or other wooden wagon component will be fined five pounds, made to replace the component at his own cost and make good the repairs to the wagon in his own time”!

This dated from about 1925. How much did a wagon repairer earn in 1925? Probably about £5 a week, so he lost a week’s wages, had to replace the timber component say another £5 and repair the wagon in his own time. And we wonder why the working man resents stupid a*****le managers!

I could go on but I won’t except to tell you that we were AUEW and once we (well I) turned this relic into profit I called the Union bloke in London and told him I was giving my men a 10% raise. This was the only time we had a fight, he did not want me to do it. Funny old life!!!

I will copy the instruction pages in due course and post them. Not too many.

Cheers David

|

|

|

|

Post by ejparrott on Feb 24, 2014 18:53:26 GMT

I look forward to seeing them, just had a look for a copy and came back with an astounding zero results!

|

|

|

|

Post by Deleted on Feb 24, 2014 19:01:43 GMT

I look forward to seeing them, just had a look for a copy and came back with an astounding zero results! ahh... me too...  |

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Feb 24, 2014 19:31:11 GMT

Lovely supper! Once I got back to Canada with my book I made some for my O gauge railway and since we produced Canadian 130t cars in batches of 50 or a 100 I decided to do the same for O gauge and did a batch of 30. It took about the same time as a one off as mass production works. Only problem is I have no idea where they got to!

OK on to the scanner!

Cheers David

|

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Feb 24, 2014 19:40:06 GMT

Will put them into a new thread!

D

|

|

|

|

Post by Doug on Mar 18, 2014 8:22:43 GMT

Well i have started by waggon i will try and post some pics when i get going so far i have just done the design and cut most of the chassis which i am making out of Aluminium there i said it ........now taking cover! I am going to weld it together and i will be using dummy axleboxes so the wheels will run on independant roller bearings after alot of thought about the construction i decided that it was the look i wanted to go for not nessasarily the correct construction. so i will build it and then dress it up to look like the real thing. it is going to be my tender for my tank engines so half of the waggon will be for coal the other half for a Tea cup  all the construction from the floor up will be dead standard while the chassis is obviously going to be for looks only, the draw hooks will pass right through so any towing will be transmitted through. The floor will give the chassis extra rigidity for the compression during braking. |

|

|

|

Post by ejparrott on Mar 18, 2014 13:24:33 GMT

Wagon draw hooks almost always pass right through. Waqons are not pulled from the front, they're pushed from the back.

|

|