|

|

Post by runner42 on Aug 30, 2014 8:16:20 GMT

Hi all, I am nearing getting the design for LBSC's Doris approved by the boiler inspector in compliance with the AMBSC Code Part 1 requirements. I hope that the changes if any from hereon in are minor details. For the record and for others Doris builders interest I have recorded the differences and changes that I had to make. I don't know if some of these changes are of a parochial nature and or they are complete and accurate so it's advisable that prospective builders check with their boiler inspectors.   Brian PS Some of the dimensions are irrational due to my lack of expertise with the CAD programme. Assume that they are all to the nearest 1/64 " fractional equivalent. |

|

|

|

Post by runner42 on Aug 31, 2014 7:40:48 GMT

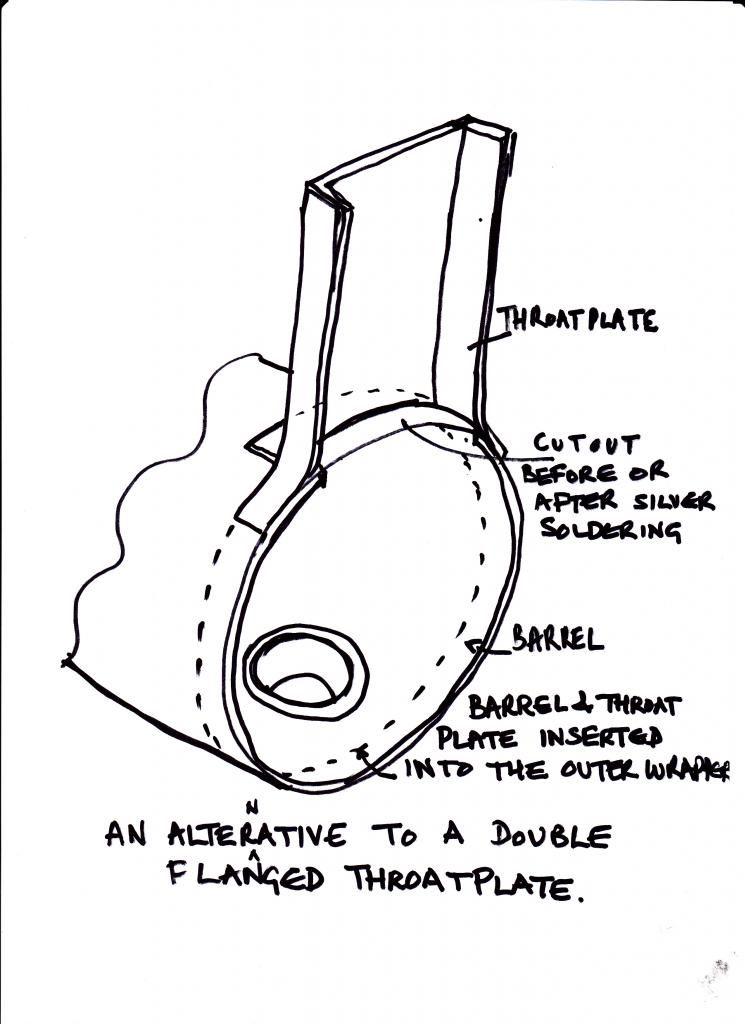

If you are wondering about the unusual throatplate configuration I have attached a sketch which will make things a little clearer. The throatplate is silver soldered to the barrel and the whole asssembly is inserted into the outer wrapper to the dotted line and siver soldered. There are two holes at the 2 o'clock and 10 o'clock positions are filled with thick shaped copper pieces. In my case it is 3 x 3mm pieces silver soldered together and then shaped to fit. Brian Brian  |

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Aug 31, 2014 8:01:19 GMT

hi brian,

that is an excellent drawing - very well done!

if i might make a few comments?

the design pressure is usually above the working pressure, so it is customary to use 100psi design pressure for a boiler having a working pressure of 80psi.

i think that 1" stay pitch is far too much for 2.5mm thick plates.

the 4 x 5/8" dia superheater flues will be virtually useless. you could easily and with considerable advantage to the steaming of the boiler and free gas flow and avoidance of blocked superheater flues have 3 x 3/4" dia superheater flues, and rearrange the smaller tubes to a better more even layout perhaps adding 1 or more small tubes of 3/8" dia. the free gas flow on a tapered boiler is restricted by the nest of tubes at the smokebox end, and anything that can assist will be of benefit so far as steaming is concerned.

if you reduce the taper on the barrel, you can fit a proper double flanged throatplate all round instead of having separate pieces at the top. this will also have the advantage of allowing the dome bush to be less prominent.

the cladding and cleading can deal with the correct outline.

i do not like water feeds below the water line - see your backhead. it is the worst place to feed water.

a square/oblong shaped firehole should be made of thicker section than a normal round or oval type. the Black 5s didnt have oblong fireholes so i see no need to fit one.

the regulator flange on the backhead provides very little room for packing around the gland, and the silver soldered bush ought to be of much greater internal diameter on the turned recess that fits into the backhead. this provides additional suppport for the backhead, plus how on earth are you going to tap this flange with only a 1/8" depth adequately? a better design is to use a larger dia than your 0.3638" with just a very small shoulder and the screws/bolts can then be taped into blind holes of greater depth in the bush if this makes sense. the same can be done for the dome bush.

3/8" x 26 tpi is far too coarse a thread for the safety valve bushes IMHO, 32 tpi being better.

i am not sure about the extension to the barrel at the smokebox end - it would be easier to make the barrel longer and shape it accordingly at the smokebox end.

the above comments are meant to be contructive and not in any way critical.

cheers,

julian

|

|

|

|

Post by runner42 on Aug 31, 2014 23:08:34 GMT

Hi Julian,

thanks very much for your valued comments. The purpose of the post was just to itemise the changes that are required to LBSC's design as a result of compliance to the code, but to use my design drawing as the vehicle to depict these changes I should expect comments on the design itself.

Firstly and easily dealt with the 3/8" x 26 TPI thread for the safety valves is an error it should be 3/8" x 32 TPI.

Secondly the square firehole was decided upon because there is a need to have a bigger opening for this reason. The driveability of 3.5" gauge 4-6-0 tender locomotive that is 1" overall longer than LBSC's design on a non raised track is going to be diffulcult. I am told that if positioned on a trolley behind the tender the driver requires arms like an ape to reach the controls so shoveling coal through the firehole especially on the move requires a long handled shovel and a very steady hand. The firehole ring can be made of thicker material I was just using the thickness used by LBSC in his oval firehole.

Thirdly the backhead clack is below the water line, this is same in so many designs my Rob Roy has both clacks at the boiler centre line and I assume was the same in full size practice. A redeeming feature is that the injector and axle pump are top feed injections.

Fourthly the 4 x 5/8" flues may not make it to the final design, heaven forbid. The boiler inspector has required that the flues and tubes should be clear of the radius sections of the tubeplates. If this requirement is enforced then I may have to reduce the number of flues to three but this decision should not be taken lightly since it has consequential affect on the superheater and headers, the latter I have already made.

Fifthly I am convinced that a transition piece is the best solution because fitting a tapered barrel to a parallel smokebox is going to be a compromise. LBSC used the smokebox tubeplate to provide entry of the boiler into the smokebox.

Sixthly I think that the novel way of getting around the diffulculty of producing a traditional double flanged throatplate is an excellent measure and should be considered. That's why I went into detail. It's not my idea but one used at my club by a very experienced model locomotive builder.

Lastly the regulator I shall have to think about. Maybe the boiler inspector will influence my thinking, after all the design drawings are not yet approved.

Brian

|

|

|

|

Post by runner42 on Sept 1, 2014 4:54:30 GMT

In anticipation of getting design approval I have made some formers for the boiler made from MDF. The inner and outer wrapper formers are also necessary to get the profiles correct. I hope this can stand up to the rigours of copper sheet forming.  Brian |

|

peteh

Statesman

Still making mistakes!

Still making mistakes!

Posts: 760

|

Post by peteh on Sept 1, 2014 6:09:52 GMT

Hi Brian,

When making the formers for my Northumbrian boiler I used MDF but had a 1/8" (3mm) steel front to them, with all hole centres in. I found the plain MDF so be struggling a little but do ensure you keep the copper well annealed.

|

|

|

|

Post by ejparrott on Sept 2, 2014 7:43:11 GMT

The tapered barrel would usually be formed back into a round profile where it enters the smoke-box, that also allows fitting of the front tube-plate.

Putting water from an injector into the boiler around the firebox isn't too bad, above or below waterline, as the water is hot. From an axle or hand pump though is really bad as the water is cold. These should always be as far forward as possible, even through the front tube-plate if space is available.

|

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Sept 2, 2014 8:00:55 GMT

hi brian,

your detailed reply didnt deal with my most important point re pitch of the stays in 2.5mm copper plate. i cannot believe that a stay pitch of 26mm is acceptable for 2.5mm copper plate. 26mm is far too much.

cheers,

julian

|

|

|

|

Post by ejparrott on Sept 2, 2014 8:30:11 GMT

I'm inclined to agree

|

|

|

|

Post by Shawki Shlemon on Sept 2, 2014 10:29:39 GMT

As far as our code is concerned , it is not matter of opinion , it is what is allowed , for 2.5 mm thick plate and stays of 5mm dia at operating pressure of 550 kpa ( 80 psi ) the maximum spacing is 26mm .

|

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Sept 2, 2014 10:43:19 GMT

hi shawki,

that rather shows that the australian code is somewhat lacking?

regardless of the diameter of the stay and stay strength, the distance between stays must take account of the plate thickness to stop the plates bulging between stays? there are 2 considerations here, only one of which (stay strength) appears to be dealt with properly in the australian code.

cheers,

julian

|

|

|

|

Post by Jim on Sept 2, 2014 11:59:38 GMT

I think as Shawki says it is the maximum stay pitch permitted, but as Julian points out a closer pitch may be preferred and in fact the boiler inspector may well recommend it.

Jim

|

|

|

|

Post by ejparrott on Sept 2, 2014 12:19:46 GMT

I think as Shawki says it is the maximum stay pitch permitted, but as Julian points out a closer pitch may be preferred and in fact the boiler inspector may well recommend it. Jim As I understand it, MAXIMUM is what is there, nothing to stop you putting them closer, but I do agree that 26mm seems awfully large. Increasing the stay diameter will not strengthen the basic plate allowing it to be supported at greater distances |

|

jackrae

Elder Statesman

Posts: 1,335

|

Post by jackrae on Sept 2, 2014 16:18:25 GMT

The problem that many people have with "standards" is a failure to comprehend that they are the MINIMUM requirement for compliance. Standards invariably fail to mention this fact and that the designer/builder may choose to enhance the quality of the build by using superior (approved) construction techniques, whilst continuing to meet the requirement of the standard. However such "improvements" must be tempered with good design practice and not introduce potential weaknesses in construction, typically by the introduction of high stress points.

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Sept 3, 2014 0:48:16 GMT

Brian Firstly let me assure others here that the AMSBC codes are conservative, Shawki is right. I question LBSC's using 4 superheater flues when a successful design like Simplex uses one. Three 3/4" flues would be a better fit. Regarding the number of tubes vs the required separation from the edges of the tube plate see if the number of tubes can be reduced. Refer to Baggo's web site www.modeng.johnbaguley.info/Loco%20design/design1.htm where he has some very useful formulae and spreadsheets to apply them. Ian |

|

|

|

Post by runner42 on Sept 3, 2014 1:48:46 GMT

Hi Julian,

I didn't address the 3/16" x 26mm stay spacing because it was covered in my stay dia and spacing thread and because the boiler inspector required that I change from 1/8" x 5/8" stay spacing to 3/16" x 26 mm as required by the code. I did so because I am a tyro in boiler design and construction and thought that 3/16" x 26mm was better than 1/8" x 5/8". However it appears from inputs from others that the unsupported area between stays is not influenced by the dia of the stay so there is a possibility that the converse is true the 5/8" stay spacing is stronger than 26mm, irrespective of stay dia used. But the code minimum requirements were based on engineering decisions, i.e design calculations. The formula D= Sq rt( 4C squared X P/72000) as I said in my previous thread shows that both stay dia and spacing configurations are acceptable. I was hopeful in my previous thread that an interested mechanical engineer would provide the rationale to how the minimum stay dia was arrived at, because intuitively I think there must be a theoretical minimum.

I am happy using the 3/16" x 26mm stay spacing, because the formula does show that there is a relationship between stay dia and spacing. But I would welcome inputs from other boiler builders on what stay dia and spacing they used in their boilers of similar size and material thickness. Reducing stay spacing and increasing stay dia merely because it results in a stronger boiler can be counterproductive if it affects the boiler in steaming ability, capacity and esoteric performance issues.

Brian |

|

|

|

Post by runner42 on Sept 3, 2014 2:00:15 GMT

Hi Ian,

I missed your post initially. Thanks for the link to Baggo's website. I am being convinced that maybe there is mileage in reducing the number of flues but obviously there is always a trade-off in having a shorter superheater pathway.

Brian |

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Sept 3, 2014 9:20:02 GMT

hi brian,

re firebox stays

there is a tendency to fit as few stays as possible as every stay requires lots of work to make, fit, deburr the holes, and then silver solder, or if comsol caulked even more work in threading the material, tapping the plates, fitting nuts etc. this is a tendency that martin evans followed but is one that i do not agree with. like Ed ive been involved in lots of copper miniature boiler tests and have often had to suggest extra stays be added.

i see no reason to depart from the stay pitch as shown by LBSC on the DORIS drawings. apologies if this means more work for you in drilling holes etc.

re superheater flues

if you are going to fit superheaters in any of our miniatures they need to be effective. i have most of the drawings for LBSC's designs for boilers, have built a few and driven far more. i am quite a big fan of the smaller gauge locos and have a lot of experience driving and maintaining them. you need to be able to clean the flues and there must be ample room around the elements for this purpose and the gases to pass. you also have to consider the additional pipework created in the smokebox and the need to keep the ends of the flues at the smokebox end free of pipework to be able to clean the flues. there are no rules about such things, just experience and personal opinion as to what arrangements work best. i dont recall any other LBSC design with 5/8" dia superheater flues in 3.5"g. in some cases ive been able to compare different boilers for the same loco such as the 2 quite different boilers he designed for his very popular 3.5"g MAISEE design, and in my view the original boiler has the edge over the 1952 version shown in the construction book. sometimes the superheater flue size is determined by the throatplate and smokebox tubeplates and a larger size simply wont fit in (eg going up from 3/4" dia to 7/8" dia) but this doesnt apply to DORIS.

incidentally the tubes transfer very little heat to the water in the barrel, but in miniature do form a very important part of the free gas flow to ensure a free steaming loco.

cheers,

julian

|

|

|

|

Post by ejparrott on Sept 3, 2014 11:22:02 GMT

It worries me that the code is being mis-intreperted (sp?). Yes it says 5mm stays and 26mm pitch, but I read that as a minimum, not a figure to be adhered to. The original 5/8" stay pitch is fine the way I read it. Yes ok make the stays larger in diameter, but that doesn't alter the fact that the plate is only supported at 26mm centers. Just this morning I've been and looking at the Romulus boiler we failed earlier in the year. Its now off stripped and upside down - beautiful bulge both sides of the inner firebox, perfectly positioned between four stays.

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,857

|

Post by uuu on Sept 3, 2014 16:47:30 GMT

hi brian, ... re superheater flues ...to clean the flues. there are no rules about such things, ... cheers, julian Sorry to disappoint you. UK boiler rules again, on pre-test preparations - item 6.9 c "Where boilers have been steamed, the smokebox, combustion spaces and surfaces shall be thoroughly cleaned and all fire tubes or flues brushed through. I suppose you could remove the superheaters each time to perform the cleaning, if you'd not left space. Yours pedantically, Wilf |

|