steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Nov 6, 2014 6:33:31 GMT

I notice that steam4ian has fallen for that old myopia trick of mis-reading that which has been clearly printed in front of him...........I used the word W-A-S-T-E ...... and those cooling towers to illustrate the heat energy literally going up in STEAM...................You won't find the word POLLUTION in MY post as that was never the subject matter in the first place ( A trick the media like to employ, apparently )....Incidentally, as the young Hagley spent his Apprentice Years and then some RN service time on the Marine version of that complete photo you can rest assured he knows the basic difference 'twixt steam and FFO exhausting..( Economisers, feedwater pre-heaters etc ).......................My understanding as to the reason why Superheaters are fitted is mainly one of ECONOMY ( Roger has hit the nail square on the head with }----"Throwing away water you've boiled but failed to expand to steam is clearly wasteful". )....Hence my photo.... It's not the water thrown away that concerns us but the heat energy still contained within it .....steam4ian's two TICH locos will give comparable results BUT the Superheated one will be using less coal to achieve it.......... Do have a thorough read of this..I've posted it before but how many actually READ it ?? >>>>>>>>>>>>>>>> en.wikipedia.org/wiki/SuperheaterAlan How can you be so sure the two Tich locos will give comparable results? I am not arguing that they won't just that a statement like that needs to be proved. In a small loco like a small boilered Tich every bit of heat must be used in order for the loco to move itself. If Tich doesn't need superheaters then clearly LBSC was undertaking manual activities which would make him blind when he described Tich as a simple beginners' loco. BTW, thanks for the Wikipedia article. No argument that in theory superheating improves economy. It could be argued that SH makes compounding an overly complex redundancy in loco service. If you like I will forward you some more technical articles on the same subject. Ian |

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,858

|

Post by uuu on Nov 6, 2014 7:36:32 GMT

To borrow some information that Julian supplied on his Boxhill thread, it would appear that there is very little if any heat supplied to the steam in the flue itself, it's mostly in the radiant part that heat is transferred. If that's the case then the inside tube of a coaxial type needs to be insulated with some kind of string else the inner tube is going to significantly cool the steam from the radiant part. That makes sense to me... But it makes no sense to me. If there's little (if any) heat moving from the flue gases into the outer superheater element, by what magic process is there lots of heat moving from the outer to the inner element? Wilf |

|

|

|

Post by Roger on Nov 6, 2014 8:17:13 GMT

To borrow some information that Julian supplied on his Boxhill thread, it would appear that there is very little if any heat supplied to the steam in the flue itself, it's mostly in the radiant part that heat is transferred. If that's the case then the inside tube of a coaxial type needs to be insulated with some kind of string else the inner tube is going to significantly cool the steam from the radiant part. That makes sense to me... But it makes no sense to me. If there's little (if any) heat moving from the flue gases into the outer superheater element, by what magic process is there lots of heat moving from the outer to the inner element? Wilf No magic Wilf, the Superheated steam at a much elevated temperature where it was heated by the radiant part in the firebox is now touching the inner tube which is much colder with wet steam. That's why I think the inside tube needs to be insulated from the steam outside it. What's going on between the flue gasses and the outer tube is a different question. |

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Nov 6, 2014 8:34:33 GMT

it is always interesting to note how a decent superheater argument creates some lively debate!

there are lots of small fullsize locos that have had replacement boilers fitted with superheaters whereas before they had none - with considerable advantage. all of the Ffestiniog Railway locos except Palmerston now have them fitted, even though some of these locos were only small shunting locos originally plus do no hard work in the downward run of the line. the same can be said of the RHDR locos and Bure Valley locos.

i think you have to read what jim ewins wrote very carefully - the odd throw away remark often turns out to be the most important point he is making!

superheater elements and their flues must be kept clean and free from obstruction for them to work, and in this respect i think that smokebox design and correct size of superheater elements to match the flues is very important. the coaxial type to my mind does not allow proper cleaning unless perhaps in the larger locos that paul drives. you also have a very large surface area on the coaxial outer tube which at first glance suggests a large area for heat transfer - but if this is made too large you end up with the steam not meeting any resistance with the walls and so very little heat transferred.

this of course is quite different to the water in the boiler which although it should circulate is (compared to steam moving along a pipe to the cylinders) relatively static and heat transfer takes place between the plates. incidentally in fullsize this heat transfer is greater with water the lower the boiler pressure - but that's another topic!

jim ewins measured the temperature of the gases in the tubes along their length. the results were surprising in that initially there was a drop in temperature for a short length, but then no further drop indicating that no heat was being transferred.

cheers,

julian

|

|

|

|

Post by Roger on Nov 6, 2014 8:46:45 GMT

Hi Julian,

Those are interesting comments about the temperature drop along the flue, because taken to their logical conclusion, you could argue that you only need say half the length of boiler and it wouldn't make any difference. I find that really hard to believe. Who fancies making half a boiler to prove the point?

|

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Nov 6, 2014 9:00:06 GMT

hi roger,

jim ewins advocated exactly that - well nearly!

the only purpose of a long barrel (and hence tubes) is as an energy store for the water capacity of the boiler plus area where the steam is released from the free water surface. my first loco was a don young Railmotor with a very short barrel and it would steam on a candle!

scaling down a long tapered barrel type boiler is most problematic due to the constraints on the tube bank restricted by the available smokebox tubeplate diameter which on a narrow firebox loco restricts the free gas flow for the size of grate.

gas velocity in the tubes jim reckoned to be 1/12 of fullsize and this also has a marked effect on everything in miniature.

cheers,

julian

|

|

|

|

Post by Roger on Nov 6, 2014 9:29:52 GMT

Hi Julian,

I don't think you need a large free water surface area for steam to escape, if the energy is enough to turn the water to steam it will float up and escape anyway. I can see that in an extreme case, you could almost end up with the tubes surrounded more by escaping steam than by water, almost turning them into superheaters. That could be a problem if carried to extreme.

Keeping a large store of boiling water does make good sense though. I remember those Fireless Locomotives and was always intrigued how they could work so long having been charged with pressurised boiling water. I guess it's the same argument, there's a lot of energy there that can be released as the pressure drops and that lack of buffering effect is exactly what makes Flash Steam Boilers a nightmare to control. As a bit of an aside, I happen to think that with the application of Fuzzy Logic to Flash Steam Boilers, you could make a far more effective locomotive boiler than the traditional type because we now finally have the technology to tame the beast effectively. Fascinating though the prospect is, I can't see it being very satisfying from a driver's point of view. It would need to be oil or gas fired and fully automatic so there'd be nothing to do.

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,858

|

Post by uuu on Nov 6, 2014 17:49:53 GMT

No magic Wilf, the Superheated steam at a much elevated temperature where it was heated by the radiant part in the firebox is now touching the inner tube which is much colder with wet steam. That's why I think the inside tube needs to be insulated from the steam outside it. What's going on between the flue gasses and the outer tube is a different question. I think the interaction between the flue gases and the outer superheater tube is in the same order of magnitude as the interaction between the inner and outer tubes: Suppose we have a boiler approx temp 150C, Flue gas say 400C, superheated steam say 300C. So if the inner element is the wet one, there's an inner to outer interface with a temperature difference of 150C. And an outer interface of about twice the size, with a temperature gradient of 100C. So a heat transfer possible about a third bigger. And a flue to boiler interface about twice the size again with a temperature gradient of 250C. So a heat transfer of about five times that of the previous layer. (And is through copper not stainless, so is possibly better again for that reason) We're saying that the flue-to-boiler heat transfer is precious little. If the flue to superheater heat transfer amount is five times smaller, then no wonder radiant superheaters outperform in-flue ones. And if the heat transfer between the inner and outer elements of our concentric superheater is smaller again, then I think it can be ignored - so no insulation required. Wilf |

|

|

|

Post by Deleted on Nov 6, 2014 19:18:24 GMT

Quote from Roger}---"I can see that in an extreme case, you could almost end up with the tubes surrounded more by escaping steam than by water, almost turning them into superheaters. That could be a problem if carried to extreme."..... Absolutely !!...Long before then the firebox crown will have collapsed anyway and your mind will be fully occupied on other, more pressing matters.....EG}---- your personal survival !!..........There is a dangerous firing practice known as "Forcing the boiler"....Here, you deliberately allow the water level to fall to approx. 1/4 gauge glass and at the same time create the maximum blast of air through the fire ( drop the reverser down to 75% )......The low water level has brought the surface width in line with the Max.

boiler diameter ( Thus max.water surface area) ....At the same time the fire is now at probably the hottest it's ever likely to be .... You can guess what the outcome is.....Max. evaporation rate....( You are almost at Flash Evaporation point !!).....The injectors are kept on but only to maintain that low level.......It takes a skilled team to achieve this and is completely contrary to normal driving/firing practices.....

|

|

|

|

Post by Roger on Nov 6, 2014 19:38:15 GMT

No magic Wilf, the Superheated steam at a much elevated temperature where it was heated by the radiant part in the firebox is now touching the inner tube which is much colder with wet steam. That's why I think the inside tube needs to be insulated from the steam outside it. What's going on between the flue gasses and the outer tube is a different question. I think the interaction between the flue gases and the outer superheater tube is in the same order of magnitude as the interaction between the inner and outer tubes: Suppose we have a boiler approx temp 150C, Flue gas say 400C, superheated steam say 300C. So if the inner element is the wet one, there's an inner to outer interface with a temperature difference of 150C. And an outer interface of about twice the size, with a temperature gradient of 100C. So a heat transfer possible about a third bigger. And a flue to boiler interface about twice the size again with a temperature gradient of 250C. So a heat transfer of about five times that of the previous layer. (And is through copper not stainless, so is possibly better again for that reason) We're saying that the flue-to-boiler heat transfer is precious little. If the flue to superheater heat transfer amount is five times smaller, then no wonder radiant superheaters outperform in-flue ones. And if the heat transfer between the inner and outer elements of our concentric superheater is smaller again, then I think it can be ignored - so no insulation required. Wilf You've lost me there Wilf. Forget about the outer tube and its interaction with the flue gasses and just think about the cooling effect the wet steam in the inner tube has on the much hotter steam the other side of the tube. You really don't want that interaction is what I'm suggesting. |

|

|

|

Post by portbury on Nov 6, 2014 20:41:59 GMT

If anyone is interested in some experimental results on the effectiveness of superheating, I can recommend Bill Hall's article "Measuring Steam Engine Performance" here: www.modeleng.org/articles.htmBill used a carefully controlled and instrumented test bed and found that 93 degrees C of superheat roughly halved steam consumption for a given power output. He showed that the main effect of superheat was to drastically reduce condensation of steam in the cylinder. Cheers Rich |

|

|

|

Post by Roger on Nov 6, 2014 20:47:20 GMT

Now that's more like it Rich, proper controlled experiments with real data.

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Nov 6, 2014 21:33:25 GMT

[/quote]You've lost me there Wilf. Forget about the outer tube and its interaction with the flue gasses and just think about the cooling effect the wet steam in the inner tube has on the much hotter steam the other side of the tube. You really don't want that interaction is what I'm suggesting. [/quote]

Roger.

In superheating we are looking at total heat energy gain to the steam. (measured by temperature of course.)

For concentric superheaters

Whilst the incoming wet steam might be cooling the superheated steam there is no actual heat lost. The wet steam arrives at the hot end of the superheater at a higher temperature and can pick up more heat allowing a superheater element to run at a higher temperature if it is of the radiant type.

The other issue is the relative heat transfer across the outer tube, steam/flue gas and the inner tube dry/wet steam interface. The area of one is much larger than the other.

Decent superheat needs higher smokebox temperatures with consequent higher sensible heat loss in the flue gases. It has already been reported that the flue gas temperature falls along the length to be at about boiler water temperature by the smokebox. Consequently your hot dry steam is being cooled by the flue gases as well as the wet steam. This leads the question, would it be better to have the hot dry steam pass down the centre tube.

Ian

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Nov 6, 2014 21:38:23 GMT

Now that's more like it Rich, proper controlled experiments with real data. Prof Bill Hall, one of the great treasures. Did anybody ever use his loco simulator program? As an aside regarding the value of SH in full size. Tractive effort for saturated locos was calculated at 75% boiler pressure and for saturated locos at 85%; the old timers knew they we on to something. Some earlier locos were upgraded with larger cylinders once they were converted to superheated. Ian |

|

|

|

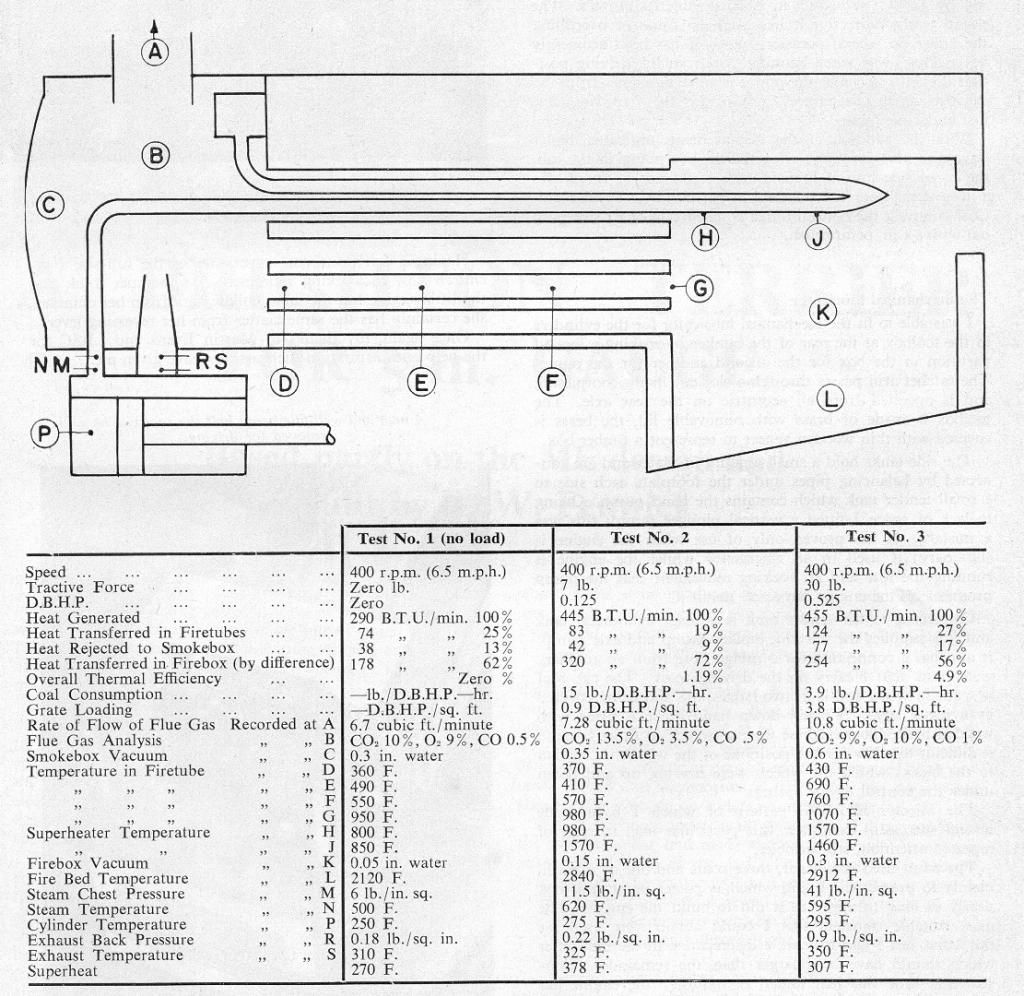

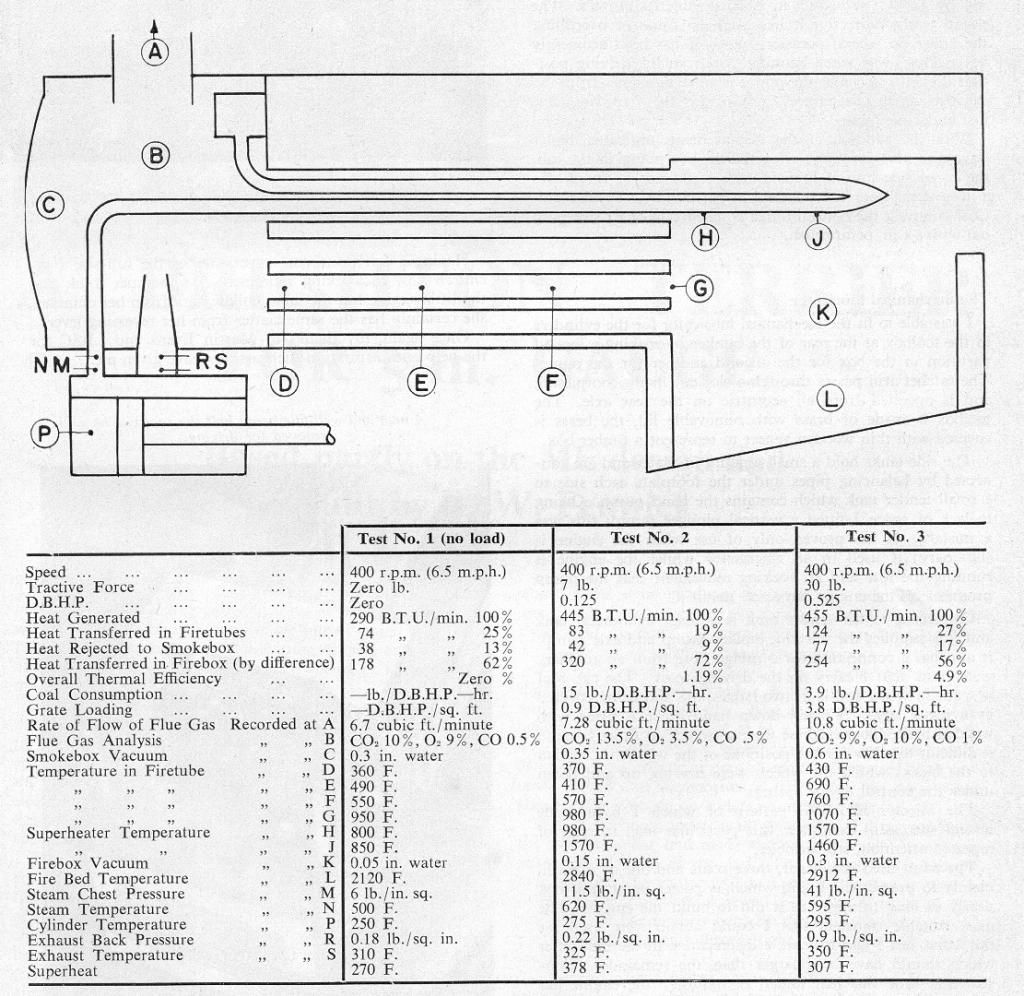

Post by Jim Scott on Nov 6, 2014 21:52:19 GMT

Roger You may be interested in Jim Ewins test results as published (I think) in ME. I'm sure Julian will have the complete article Jim S  |

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Nov 6, 2014 22:12:03 GMT

Jim Scott's own results last year using very modern tech accords with Jim Ewins' finding some 47 years previously!

i do indeed have both the full article published in martin evans' 'model locomotive boilers', and the SMEE journal (my own copy is covered with my pencilled conversion to celcius - ive never understood faranhiet!).

i was also introduced to jim ewins very many years ago by his great friend bert brock of the SMEE in 1985.

jim's guiding principle was that you cant avoid the effects of scale, and cant avoid the effects of science! i dont agree with everything jim ewins wrote or expounded upon as my own empirical experience is somewhat different, nor was he an easy guy to get on with, but he remains one of the very great model engineers of the 20th century, and anyone seriously interested in this hobby should consider carefully everything jim wrote.

cheers,

julian

|

|

|

|

Post by Roger on Nov 6, 2014 22:13:58 GMT

You've lost me there Wilf. Forget about the outer tube and its interaction with the flue gasses and just think about the cooling effect the wet steam in the inner tube has on the much hotter steam the other side of the tube. You really don't want that interaction is what I'm suggesting. [/quote] Roger. In superheating we are looking at total heat energy gain to the steam. (measured by temperature of course.) For concentric superheaters Whilst the incoming wet steam might be cooling the superheated steam there is no actual heat lost. The wet steam arrives at the hot end of the superheater at a higher temperature and can pick up more heat allowing a superheater element to run at a higher temperature if it is of the radiant type. The other issue is the relative heat transfer across the outer tube, steam/flue gas and the inner tube dry/wet steam interface. The area of one is much larger than the other. Decent superheat needs higher smokebox temperatures with consequent higher sensible heat loss in the flue gases. It has already been reported that the flue gas temperature falls along the length to be at about boiler water temperature by the smokebox. Consequently your hot dry steam is being cooled by the flue gases as well as the wet steam. This leads the question, would it be better to have the hot dry steam pass down the centre tube. Ian[/quote] I'm not convinced that the insulating the inner tube would make no difference. I would argue that the amount of energy that the steam can absorb in the radiant superheater is greater if there's a larger temperature differential between the incoming steam and the superheater walls. That would be the situation if the inner tube was insulated. That extra amount of energy would then have less losses on its way back to the smokebox. If that was the case, there would be a greater net gain of energy in doing that. I don't think it's a simple situation at all. If you insulate, the flow velocity on the feed tube will be lower because the steam is more dense. It really needs a whiz kid with FEA for make the models and show us what happens in different scenarios. I think the situation is far more complex than any of us can visualise. I don't think it's clear how to get the most energy from the fire into the steam in this situation. I doubt is anyone has experimented with insulated inner tubes with the flow in either direction. There's a lot more research to be done before there are any concrete conclusions in my opinion |

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,858

|

Post by uuu on Nov 7, 2014 7:47:32 GMT

..... For concentric superheaters ...... This leads the question, would it be better to have the hot dry steam pass down the centre tube. Ian It must be better this way round. Wilf |

|

|

|

Post by ejparrott on Nov 7, 2014 12:31:51 GMT

Did anybody ever use his loco simulator program? Ian Father had a lot to do with it |

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Nov 7, 2014 19:56:13 GMT

can i just point out that the jim ewins table posted by Jim Scott above is one of THE most significant pieces of research ever undertaken on a 5"g miniature loco (jim ewins' famous 5"g 0-6-2T loco - which ive driven). many thanks Jim for posting same!

it deserves the most careful scrutiny and study.

cheers,

julian

|

|