|

|

Post by cnc3d49 on Mar 17, 2016 20:05:52 GMT

Gentlemen

Some months ago I was having problems with a Baldwin C19 because the front of the ash pan would fill up after about two hours of passenger hauling and I would loose the front half of the fire. In conversation with a friend, he suggested I try a Rosebud grate which has cured the problem of ash build up through improved combustion. Since then several pals in the Society have fitted Rosebud grates, all with much success. However there were concerns as to how the grate would behave in boilers with sloping grates. Various opinions seemed to suggest that the fire would behave like a fluidised bed and the coal would migrate to the lowest point. In practice this does not appear to be a problem, however I thought it would be interesting to make a video of the fire under load to see what actually goes on behind the firebox doors. Quite alarming!

I've uploaded a video on to youtube hoping it will be of interest to others.

youtu.be/VQJIoHUj2VI

GeoffV |

|

|

|

Post by andyhigham on Mar 17, 2016 20:42:52 GMT

Wonderful video.

I have been contemplating a rosebud grate in my 3 1/2" Martin Evans "Conway". My main problem is unburnt coal particles filling the smokebox.

There was a good article in ME a couple of months ago

|

|

|

|

Post by chris vine on Mar 17, 2016 21:31:16 GMT

Very good film!! "hat a good experiment, I will now have to try the same thing!!

Chris.

|

|

|

|

Post by Jim on Mar 17, 2016 21:37:11 GMT

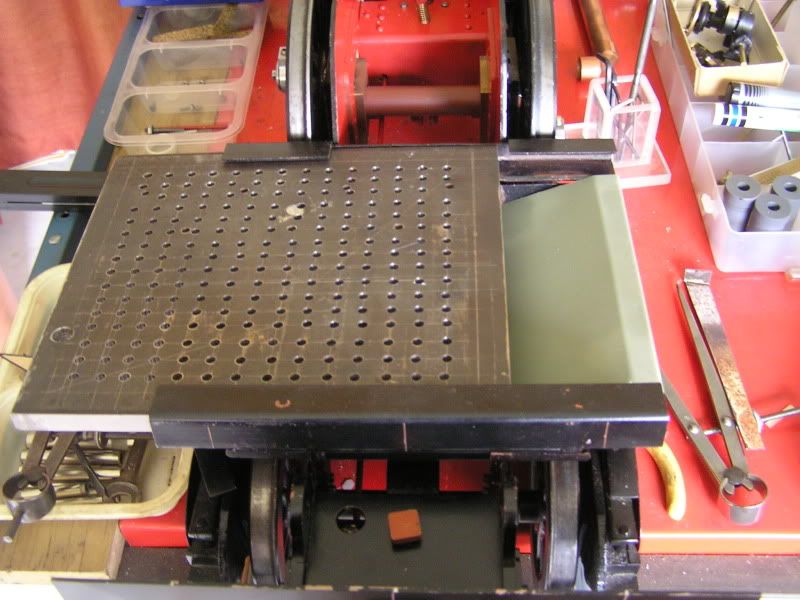

Agreed, it is a wonderful video Geoff and gives a clear indication of the how the fire burns under various operating conditions. Ive fitted an rosebud grate to my Britannia though it is yet to see its first fire but if the experiences of others in the club with similar locomotives, ie NSWGR C38 Pacifics is any thing to go by they work exceptionally well and we burn char rather than coal though that is in a process of change as the char supplies become scarce. This a photo of the rosebud grate I've fitted to Boadicea. I made up a spread sheet to calculate the number and size of holes to give a 10% air flow which is the rate recommended here. The option is there to either increase or rearrange the air flow by blocking off or enlarging the holes if required.  Thanks again for posting the video, it's the first time I've seen a rosebud grate in operation and in such detail. Jim |

|

|

|

Post by dhamblin on Mar 17, 2016 21:44:12 GMT

The Sutton Model Engineering Club have also experimented with this design of grate - see the Winter 2015 newsletter on their website. www.suttonmec.org.uk/Positive results seem to be obtained from the limited trial running. Regards, Dan |

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Mar 17, 2016 22:07:07 GMT

G'day Dam

Is there any way you can make that article from Sutton MEC more accessible?

Geoff, that is a great piece of filming. What was the fuel used and what size were the lumps. From the film I guess there would have been a fair amount in the smoke box at the end of the run. This consistent with one local driver reports when using a rosebud grate with BM char; no clinker but a full smoke box. On a bar grate he experienced clinkering.

Did you get much ash? With the bar grate did your ash contain a lot of unburnt fuel that fell through the grate?

Has any one used a rosebud grate with anthracite?

|

|

|

|

Post by dhamblin on Mar 17, 2016 22:51:44 GMT

Unfortunately not - I can't isolate the hyperlink for the Newslink archive page, let alone the specific pdf file.

Go to the 'Newslink Archive' link on the left hand side of the homepage, then the Winter 2015 one should be on the top right of the index page.

I'd be interested to hear anyone's experience with this design of grate on a 3 1/2" loco.

Regards,

Dan

|

|

|

|

Post by cnc3d49 on Mar 18, 2016 6:52:55 GMT

steam4ian

The fuel I use is a dry steam coal from Signal fuels, anthracite grade 1 in bean size, 20mm or there abouts. With a bar grate I found a lot of unburnt grains of coal in the ash pan, yet with the RB grate there is virtually no ash in the pan and not much if any more in the smoke box when compared to a bar grate. Furthermore have seen no indication of clinkering at all.

Will try to find time to make a video with a bar grate installed for comparison.

GeoffV

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Mar 18, 2016 7:22:12 GMT

Geoff

Thanks for the response. I noted a lot of sparks which is consistent with my short experience with the SAME coal; we have just started using it. It looks like the beans almost explode when the fire is pushed.

With my bar grate with 5mm spacing I get a lot of unburnt fuel in the ash pan and lots of ash also ash up to the bottom row of tubes in the smoke box.

I just obtained some stainless bar for a new grate but it looks like I had better look for a piece of plate.

Ian

|

|

|

|

Post by Jim on Mar 18, 2016 7:59:25 GMT

Geoff's observations are consistent with what I saw at Orange when the Rosebud grates were withdrawn from the two visiting 38s at the end of the day. There was no clinker, no unburnt fuel just very fine dust like ash most of which had fallen through into the grate. The fuel used was char.

Jim

|

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on Mar 18, 2016 8:31:10 GMT

|

|

|

|

Post by gingerneer on Mar 18, 2016 9:54:27 GMT

I have been having a play around with then, in both Ayesha and Canterbury Lamb. I burn anthracite grains in them. They work, although i think i could run will a thinner fire. The video shot a Frimley show Ayesha running with the new grate so far i have on run her 2 times with this grate and am still learning. I open the firehole door for a few seconeds but it not easy to see whats happening (58 seconds and 3.16 seconds). This is only a hunch, but in the smaller scales and smaller grates the effect is less than in the larger grates, it still works but the coal being larger proportional to the holes, the actions of the coal being moved around by the jet of gas/air coming through the holes is less. If that makes sense. More testing/driving is needed. What that grate has done is even out the combustion, this is most noticeable on Canterbury Lamb, the grate is half the size of Ayesha's. Photos of the 2 grates. The bar type is the stainless steel wedge style. The rosebud grate was made from an off cut of 5mm steel plate.  2 1/2" gauge LBSC Ayesha 2 1/2" gauge LBSC Ayesha by tapdieuk, on Flickr  2 1/2" gauge LBSC Ayesha 2 1/2" gauge LBSC Ayesha by tapdieuk, on Flickr |

|

|

|

Post by Jim on Mar 18, 2016 10:59:26 GMT

Thank you Lisa for locating that link. I've saved the article for future reference for when I eventually get to fire up Boadicea.

Jim

|

|

|

|

Post by keith6233 on Mar 18, 2016 15:20:50 GMT

Gentlemen

Some months ago I was having problems with a Baldwin C19 because the front of the ash pan would fill up after about two hours of passenger hauling and I would loose the front half of the fire. In conversation with a friend, he suggested I try a Rosebud grate which has cured the problem of ash build up through improved combustion. Since then several pals in the Society have fitted Rosebud grates, all with much success. However there were concerns as to how the grate would behave in boilers with sloping grates. Various opinions seemed to suggest that the fire would behave like a fluidised bed and the coal would migrate to the lowest point. In practice this does not appear to be a problem, however I thought it would be interesting to make a video of the fire under load to see what actually goes on behind the firebox doors. Quite alarming!

I've uploaded a video on to youtube hoping it will be of interest to others.

youtu.be/VQJIoHUj2VI

GeoffV H! Geoff With the C19 being having a large firebox what size holes did you use in the grate i have the same problem with a 7 1/4 Lyn ,the group building the full size replica have modified the rear pony truck to accommodate a larger ash pan. |

|

|

|

Post by Roger on Mar 18, 2016 15:41:15 GMT

That's an excellent video, and shows how little we can know about what's going on behind closed doors. It certainly makes it clear why there's a lot of energy being released when you can see it live like that.

Can someone tell me what gauge the locomotive was in the Sutton article, the dimensions don't really tell you anything if you don't know the scale. I'm certainly going to go down this route, they are so simple to make.

|

|

|

|

Post by Donald G on Mar 18, 2016 16:45:23 GMT

At the Colchester Club, we have a 5" Sweet Pea which runs well, but following the article in ME re Rosebud grate, he has made one and tested it. The loco is using less anthracite and it is noticeable that the residue is fully burnt out fine ash.

A number of members are now looking at making the Rosebud grate, myself included.

Donald

|

|

|

|

Post by cnc3d49 on Mar 18, 2016 17:26:58 GMT

kieth6233

The C19 grate has 4mm holes on a 10mm grid with an outside gap around 1mm wide. Keep the gap down as it can easily add another 5-10% pass area.

GeoffV

|

|

|

|

Post by andyhigham on Mar 18, 2016 19:45:59 GMT

I was just thinking about grates, with a "conventional" grate most of the combustion seems to happen in a small area in the centre.

If this occurred in a rosebud grate it would be easy to open up the holes in the cooler areas to get an even temperature fire over the whole grate

|

|

|

|

Post by keith6233 on Mar 18, 2016 20:08:44 GMT

kieth6233 The C19 grate has 4mm holes on a 10mm grid with an outside gap around 1mm wide. Keep the gap down as it can easily add another 5-10% pass area. GeoffV Thanks for that Geoff. Keith |

|

|

|

Post by Roger on Mar 18, 2016 20:26:13 GMT

I was just thinking about grates, with a "conventional" grate most of the combustion seems to happen in a small area in the centre. If this occurred in a rosebud grate it would be easy to open up the holes in the cooler areas to get an even temperature fire over the whole grate Looking at the pictures of Conventional and Rosebud grates side by side, it's striking how much smaller the area is for the air to come through on the Rosebud grate. Perhaps this makes it more even anyway, because it can't let too much air through the middle as there isn't enough area for that to happen? If you can get more heat from this type of grate, it makes me think that there's too much air getting through on a conventional grate. I certainly like the idea that you can easily change the area from region to region. I guess that only by filming it in action like in the video will you be able to see what, if anything, needs changing. |

|