|

|

Post by joanlluch on Sept 26, 2017 18:57:59 GMT

What materials are normally used or can be used for boiler lagging? One of the most obvious choices to me was Fiberglass Fabric. It's strong, has a very low thermal conductivity, relatively cheap, and it is adaptable to any surface. On the negative side, I found that the fabric tends to dismantle and it easily becomes a mess, as soon as you attempt to make a hole or a cut in it. I also found that Cork Sheet of the appropriate thickness is sometimes used in Germany and The Netherlands. It seems to work just fine and I have also seen the same material used locally with no issues. However, I understand that this material is at its temperature range limit when used on a locomotive boiler, and it's possibly not suitable if you attempt to insulate a smokebox. Other options that I found include glass or ceramic based wool sheets. For example Superwool Paper from Morgan thermal ceramics, or Insulfrax Paper from Unifrax. Eventually, I had the chance to see and touch the said ceramic paper from Unifrax, at a specialist shop just next to my location. I found it to be much weaker than fiberglass fabric, maybe similar to natural cork in this respect, and it's pretty easy to cut and make holes in it to adapt to boiler fittings. Insulation properties are not as good as cork or fiberglass, but still in an excellent range. So, what do you think? What insulation materials have been traditionally used in the past, or what is commonly used nowadays? |

|

|

|

Post by Roger on Sept 26, 2017 21:30:22 GMT

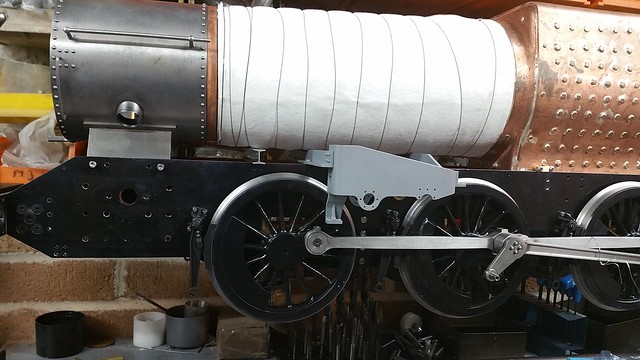

Hi Joan, I don't know what's traditionally used but I bought this from Camden Miniatures. It's not particularly strong, but you can cut it with scissors or a scalpel and it keeps its shape reasonably well. This is what it looks like on the locomotive, I've used cotton thread wound round to hold it in place.  20170917_163716 20170917_163716 by Roger Froud, on Flickr You definitely need to wear gloves when handling this though, it's fibres get straight into your skin like fibreglass does. |

|

|

|

Post by jon38r80 on Sept 26, 2017 21:41:19 GMT

Cerami blanket is used for its fire resistance/protection where thickness is an issue rather than its insulation properties for the protection of steel frames in construction. The main steel frame of th HSBC headquarters in HK used it for that reason. Never used it for its thermal performance. I seem to recall its expensive.

Jon.

|

|

|

|

Post by 92220 on Sept 27, 2017 8:00:03 GMT

Ceramic fibre, as Roger is using, is the best insulator for boilers. I used to sell Kaowool ceramic fibre, made by Morgan Creamics, at Precision Paints. I got pointed towards ceramic fibre by Tomorrow's World, on BBC, back in the 1990s. They had someone have a 1/2" thick piece of ceramic fibre blanket on his hand, and someone played a gas torch on it from about a foot away! NOT the sort of thing to risk doing at home though!!!! The best for our purposes is the 1/8"(3mm0, like Roger is using. As Jon says, it's not cheap, but is the best insulator. You have to be careful which brand you buy. Some do have health risks. Kaowool, though, is advertised as having 'excellent handleability'. Morgan Ceramics, who make Kaowool, are a UK company too. Here is the website that gives the full specification:- www.barteltinsulation.com/pdfs/CERAMICBLANKET.pdf Hope that helps. Bob. |

|

|

|

Post by joanlluch on Sept 27, 2017 10:37:24 GMT

Hi Roger, Thanks for your reply. I am sure the material you are using is Ceramic Fibre, possibly from the first manufacturer (Morgan Thermal Ceramics). Eventually the same (or similar) material can be bought online from RS-Components. Here's a link to the UK store for price references in GBP uk.rs-online.com/web/p/thermal-insulating-sheets/7248906/. What I do not get is why the price per metre from several sources is so different. I agree some basic protection is required to handle this product, although I found is not that punchy as glassfibre fabric. I have a clearance between the boiler and the cladding of 4.35 mm around the boiler tube and 4.5 mm around the firebox. Clearance is not equal because of the odd dimension of the tube (168.3 mm OD) that I am going to use for the boiler. I figured out that a 6mm thick ceramic paper sheet can be easily compacted in 4mm, so that's what I attempt to do in principle. I also need to insulate the smokebox section because I will have a water preheater heat exchanger in there, so from this point of view that seems the right material. However, I would be happier with the better insulation figures of natural cork, so I may consider using ceramic fibre on the smokebox section, and cork elsewhere. |

|

|

|

Post by joanlluch on Sept 27, 2017 10:38:00 GMT

Hi Jon,

That's as well my point. Ceramic Fibre is kind of overkill for the temperatures we are using it. It's indeed more intended to provide heat protection against very high temperatures, than to provide a true effective insulation at the much lower temperatures of our boilers surfaces . In fact, manufacturers do not usually specify any thermal conductivity data at such relatively moderate temperatures (compared with the material abilities). So that's why I think there should be something better for our use. Are you using something else?

|

|

|

|

Post by joanlluch on Sept 27, 2017 10:38:45 GMT

Hi Bob,

Yes, your post is helpful. Morgan Ceramics is one of the suppliers I mentioned on my opening post. There's possibly a distinction between the spec I posted (Superwool) and the one you posted (Kaowool), also this manufacturer may keep using these denominations for products that are continuously evolving. The Kaowool product seems to have slightly better specs though, but somewhat less health security. Health hazards for this kind of products came from breading their tiny fibres that get stuck in our lungs, possibly causing lung cancer years later. The other manufacturer I mentioned, Unifrax, is also headquartered in the UK, eventually, although I never think these things are coincidental.

|

|

|

|

Post by arch1947 on Sept 27, 2017 22:50:43 GMT

I used balsa on my Virginia. Soaked in water and held around the boiler it dries conforming to the shape. Works fine.

Arch

|

|

|

|

Post by 92220 on Sept 28, 2017 8:30:54 GMT

Hi Bob, Yes, your post is helpful. Morgan Ceramics is one of the suppliers I mentioned on my opening post. There's possibly a distinction between the spec I posted (Superwool) and the one you posted (Kaowool), also this manufacturer may keep using these denominations for products that are continuously evolving. The Kaowool product seems to have slightly better specs though, but somewhat less health security. Health hazards for this kind of products came from breading their tiny fibres that get stuck in our lungs, possibly causing lung cancer years later. The other manufacturer I mentioned, Unifrax, is also headquartered in the UK, eventually, although I never think these things are coincidental. Hi Joan.

It's such a very long time ago since I first came across Kaowool, I had forgotten a little test I did with the sample they sent me, to test it's insulation properties, before deciding to stock it. They sent me an A4 piece of 1/8" Kaowool 'paper' which I cut in half with scissors. I boiled up a large saucepan of water and, rather gingerly, lifted it up, 2 handed, with the Kaowool, when it was boiling, and held it for a minute or so, and I just felt it warm. That decided me.

As far as toxicity goes, I sold Kaowool for over 10 years, and cut hundreds of pieces for sale. I had a lot of contact with it and have had no ill effects. When used on a model, the insulation is covered by the cleading so there would be no continued contact anyway. I googled 'Kaowool Health Hazards' and read a great long screed about it. Bearing in mind that our contact would be minimal compared with contact in an industrial environment, there wouldn't be any significant risk. I have no worries about using it on my boiler.

Bob.

|

|

|

|

Post by joanlluch on Sept 28, 2017 11:46:30 GMT

Hi Bob,

Thanks for the additional info.

About possible health affectations after using such kind of materials, this is a subject that is OVERLY played by authorities. I absolutely agree that there is no risk on using them. Even materials with great general concerns such as asbestos are not as dangerous as they are claimed too. These NATURAL materials have been used for decades. In fact, there is a lot more of economical interest built around it than actual health hazard. The European regulation that covers the inhalation of small mineral fibres and particles, particularly asbestos and other silicates, is laughable in some aspects because the naturally occurring amount of these particles in normal air is already above the max allowed concentration specified in the norm, specially in areas with dry climates. So according to the regulation, we should be wearing protective masks all day just for breading normal air. This is just ridiculous. I mean, it is ok that the required precautions be taken by personnel with everyday exposure to it, such as factory or mining workers, but it's just plain unjustified (in my opinion) to have any concern at all with normal occasional use of already processed products based on these materials.

|

|

|

|

Post by steamer5 on Sept 28, 2017 21:03:52 GMT

Hi Joan,

Another option that an old guy in our club used.......cornflake packet cardboard ! He used to use a couple of layers! Times have moved on Kaowool would be a vast improvement!

Cheers Kerrin

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Sept 28, 2017 22:36:35 GMT

There is a guy at our club who advocates the use of the insulating material from ironing board covers, no idea what it is but it might be worth investigating.

Mike

|

|

|

|

Post by 92220 on Sept 29, 2017 18:50:54 GMT

Hi Joan.

You are absolutely right!! A load of rubbish is piped out by the authorities and 'experts', and it has very little relation to normal life.

Bob.

|

|

|

|

Post by joanlluch on Sept 29, 2017 23:06:17 GMT

Hi Joan. You are absolutely right!! A load of rubbish is piped out by the authorities and 'experts', and it has very little relation to normal life. Bob. Ha Ha, I have my own particular opinions about certain regulations and "experts". In a previous role as technical manager of a chemical company, I spent an awful amount of time in meetings with bureaucrat authorities in Brussels to try and convince them to ease a norm on supposed health hazards of a nano-sized form of calcium carbonate, which of course is totally harmless to humans. A lot of money was spent to prove what already was obvious from the beginning. One day, I will inevitably resurface the subject of copper boilers and boiler "expert" inspection. In the same wording context that you used above.Then not everybody will agree with me... |

|

|

|

Post by jon38r80 on Oct 1, 2017 8:34:42 GMT

I'm afraid I don't build steam models so have no alternatives to suggest. It was just that I was surprised at the use of ceramic blanket in this way. Having said that it will probably do the job pretty well. Roger's amazing model will be the proof of the pudding when he has the cladding on and steamed up.

Jon

|

|

|

|

Post by joanlluch on Oct 1, 2017 9:21:28 GMT

I'm afraid I don't build steam models so have no alternatives to suggest. It was just that I was surprised at the use of ceramic blanket in this way. Having said that it will probably do the job pretty well. Roger's amazing model will be the proof of the pudding when he has the cladding on and steamed up. Jon Unless I finish mine before, of course. (Not serious) |

|