|

|

Post by Jim on Jun 9, 2011 10:48:04 GMT

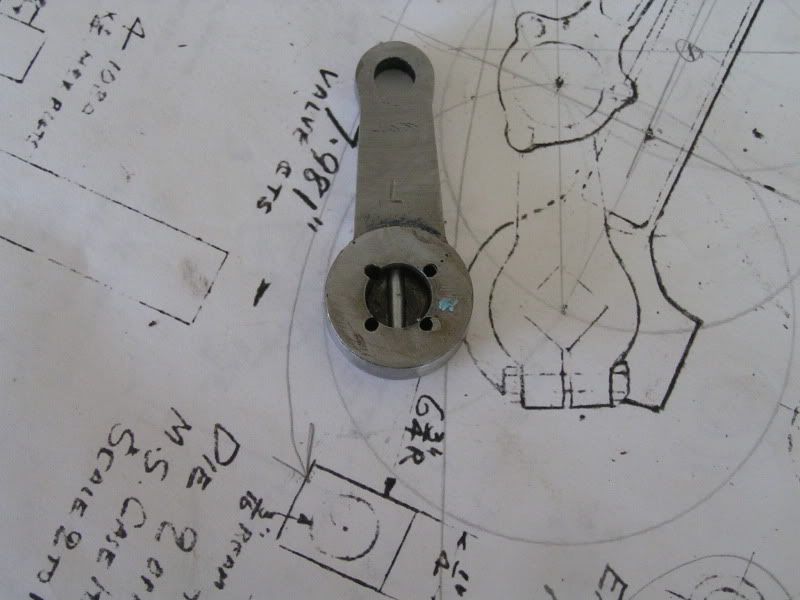

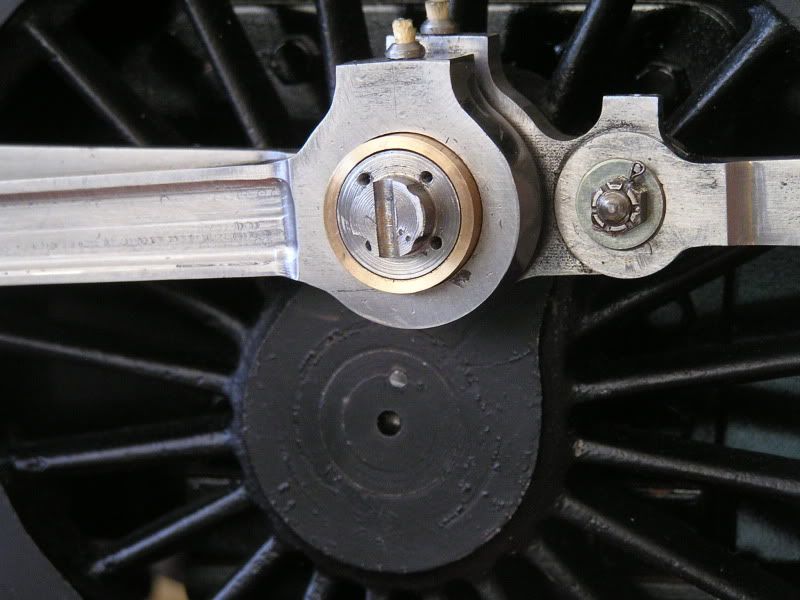

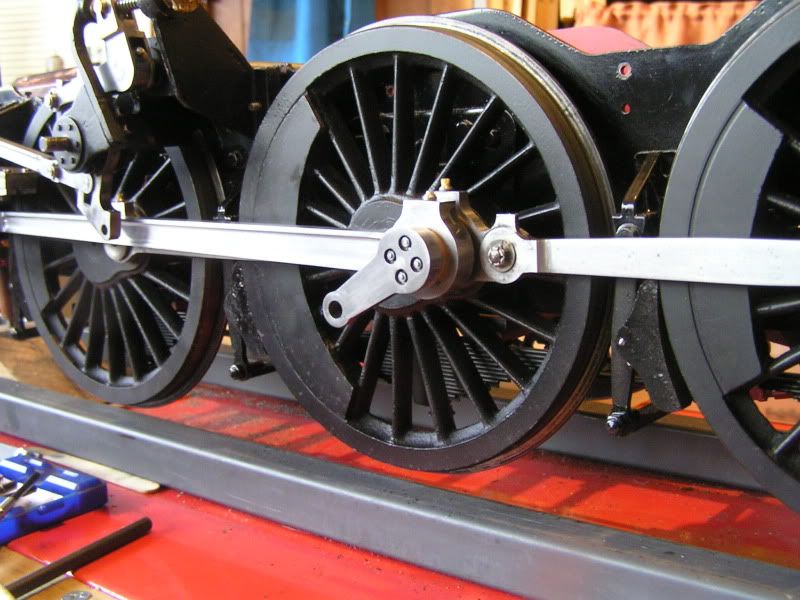

Since returning from sunny Yorkshire I've been busy working on Boadicea's valve gear. The initial task was to replace the 'as drawn', crank with the typical 4 stud return crank that Boadicea carried in service. What I thought would be a problem quickly resolved itself with a close look at the drawing on Don Ashton's site along with a fresh look at the great photos JJ (aka Britania Builder) took of of Oliver Cromwell's restoration. After some heart stopping moments the cranks have been now completed and set to the pitch circle. I made up a trammel to determine the exact length of the eccentric rod, I must say this has turned out to be a very handy tool. The pictures show the construction of the crank, the trammel and the trammel in action.      There are still some more adjustments to be made before all is set but hopefully it won't be too long before Boadicea runs on air.  Jim |

|

|

|

Post by Deleted on Jun 9, 2011 11:09:11 GMT

Lovely work Jim and it's great to see Boadicea again, I like the idea of using a trammel and intend to do the same when I reach this stage. I think I first saw this method on John's( baggo) site. Seems to me the best way of getting a smooth running motion. Keep the pics coming....  Pete |

|

|

|

Post by Jim on Jun 9, 2011 11:43:11 GMT

Hi Pete, The trammel certainly does the job very accurately with the added benefit of letting you turn the wheels to observe the whole cyclic action and pick up any unforeseen problems such as a setscrew I found that interfered with the back swing of the expansion link when in full forward gear.  Jim |

|

|

|

Post by donashton on Jun 9, 2011 17:17:08 GMT

Jim,

Glad if you found my site useful and how nice it is to see due attention to accuracy. The common 'adjustable' return crank is a poor substitute for a positive drive, as the loads can be quite high on this component. Imagine the full size engineers fitting return cranks on short round stubs and using grub screws to mount eccentrics on an axle!

I remember the excitement when the original (unfaded!) Perrier drawings appeared and long mourned the demise of both the helpful Wilwau and their castings.

Don

|

|

|

|

Post by Jim on Jun 10, 2011 5:02:42 GMT

Thank you Don. I must say that I really couldn't see the woods for the trees when considering how to replicate the standard 4 stud return cranks for Boadicea. I have your book but it wasn't until another modeller drew my attention to the works drawing of the return crank on your site that the penny dropped. 'A tongue and groove'. With the trees out of the way I then realised Henry Greenly had it sitting there in model form all the time in Fig 232-Typical return cranks for Walschaerts' valve gear. Oh dear!  As with the full size cranks, the design allows for the removal and replacement of the cranks without any loss of settings. In operation the turning loads are carried safely by the tongue and groove with the studs retaining the crank, again as in the full sized version. Jim. |

|

|

|

Post by Jim on Jun 20, 2011 9:51:25 GMT

As discussed in Keith's thread, modeleng.proboards.com/index.cgi?board=general&action=display&thread=6380 I've been sorting out the valve gear on Boadicea in light of the invaluable advice of Keith and Don. I made a simple but very effective guage to determine the exact distance between the outer edges of the inlet ports as a pre requisite to making the valve bobbins and before any one asks I must admit they weren't the same  With that job taken care of I then set up the DTI to measure the valve travel through full forward, mid gear and full backward gear. With the fireman's side taken care of I now only have the driver's side to do. While there are some very detailed books on the design of Walschaerts' Valve Gear as a modeler, working to a set of plans I think I really need a book called 'Walschaert's for Dummies'  With such a book in hand I'm sure my head wouldn't be spinning like a top nor would I wake from nightmares of having to remake the valve gear. In reality though I am very grateful for the way in which modelers such as Don and Keith have shared their very extensive knowledge and with their help I've started to gain an appreciation of what I should be looking for. Jim the guage  measuring the ports  measuring the valve travel  |

|

|

|

Post by donashton on Jun 20, 2011 11:06:22 GMT

Jim,

Your gauge is exactly the correct one - you are measuring the essential datum which not only confirms what ports you have (as opposed to the drawing) but with a little thought and ingenuity this datum enables valve setting from outside the cylinder, as in full size. They don't have silly 'sight holes' or need the steam chest cover off. In any case the eye cannot gauge to the accuracy required.

Walschaerts' gear is too complex for a Dummies book to tell you all but basics, and you will recognise that distances within the valve travel give no indication of the time taken to get from A to B anyway. To avoid a common delusion, a gear usually produces less port opening at the front port than the rear, yet examination shows that the front port is open for longer - almost like a built-in compensation. Therefore ignore any advice (in or outside text books) to set valves for equal port openings, as you are unwittingly setting all other events out of symmetry. This port opening asymmetry continues but reduces right to mid gear. If you watch the gear revolving slowly you can easily see the longer dwell at the front end.

It is also as well to remember that gears were invented before the demand for long valve travels and inside admission (like the Brits) and often suffer asymmetry port-to-port as a result, despite all ingenuity. Oh! And why does the production of a new valve gear part cause a nightmare?

Don

|

|

|

|

Post by Jim on Jun 20, 2011 14:08:04 GMT

Thank you Don for taking the time to explain port opening asymmetry, an issue I haven't as yet encountered but clearly will as work progresses.

I have said it before but your comments and observations have done much to clarify the key issues in what is as you say, a very complex issue.

Hopefully I can translate that advice into a sound working valve gear.

Jim

|

|

|

|

Post by Jim on Jun 26, 2011 10:23:00 GMT

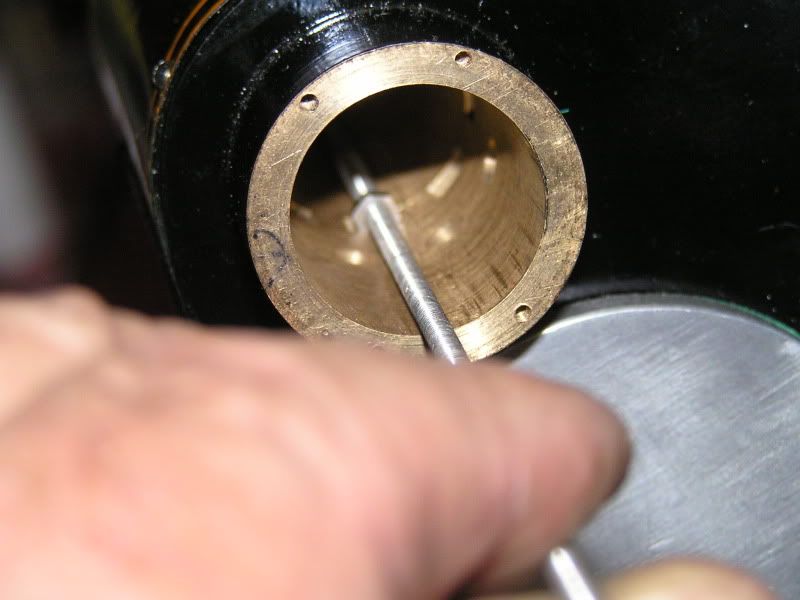

Today marked a big milestone. With only the right hand cylinder operational, the left still waiting for its test valve, Boadicea ticked over on air at about 12psi.   The photo shows the test valve and the stainless valve spindle with the valve adjusting threads in place. The valve 'floats' on the spindle and is retained in place by lock nuts which hadn't been made at the time I took the photo. Combined with the fine thread to the fork the valve can be accurately adjusted to the optimal settings. Jim  |

|

|

|

Post by donashton on Jun 26, 2011 22:16:23 GMT

Congratulations Jim. It's always nice to reach that stage.

A word of warning - many joyfully run on air without an oil feed (light - not steam oil) and in their elation forget the water content in the air. I've seen cases a only week later when the piston needed heavy hammering to get it to move!

Don

|

|

|

|

Post by RGR 60130 on Jun 26, 2011 22:19:10 GMT

Well done Jim. As you say, it's a major milestone. I can still remember when I got my first engine to run. It was in the boot of the car at the local petrol station. I didn't have an air compressor at home so I used the petrol station airline. At 10 pence for a few minutes I spent a fortune watching the wheels go round ;D

Reg

|

|

|

|

Post by Jim on Jun 27, 2011 1:14:13 GMT

Thanks Don & Reg, It really is, as you say a moment to savor. Thanks Don too for your very helpful comments, I'm just about to get the plans done for you to study and add to your collection. It was probably lucky Reg that I was not at the local servo as the police would have been called to deal with a elderly man in the driveway dancing and jumping around while shouting and yelling joyfully.  Jim |

|

|

|

Post by donashton on Jun 27, 2011 8:17:12 GMT

Reg,

What a resourceful man you are. Did you not capture the act on video for posterity?

Don

|

|

|

|

Post by RGR 60130 on Jun 27, 2011 16:57:33 GMT

Hi Don,

I wish I had been able to record it on video. Unfortunately camera phones and the like hadn't even been dreamed of back in the mid 80s. The event is still indelibly recorded in my head but unfortunately that doesn't make for easy sharing! Come the day I get my Peppercorn A1 to that stage I'll definitely record the moment. At current rate of progress they'll probably have a 3D camera in every phone by then.

Reg

|

|

|

|

Post by Jim on Jun 28, 2011 13:33:15 GMT

I'm not sure if this will work but the link should show Boadicea ticking over on around 15psi. and using the eccentric rod trammel.  At present the piston valve is a trial one made from Delrin for the sole purpose of checking that the dimensions are correct for the RHS. I have yet to make the left hand valve and once it's done and checked and Boadicea run with both sides working satisfactorily I will then make the permanent working valves and two eccentric rods. Jim s272.photobucket.com/albums/jj163/Jamandmarge/70036%20Boadicea/?action=view¤t=70036Boadicea.mp4 |

|

|

|

Post by Jim on Jun 28, 2011 13:43:09 GMT

Blimey your quick Mike I've only just put it up there. Opened the smoke box door today as a special treat, I have be careful though as it is addictive  Jim

|

|

|

|

Post by Deleted on Jun 28, 2011 15:26:35 GMT

That looks great Jim, I bet your chuffed, I am watching it and it's not even mine...  Pete |

|

|

|

Post by Jim on Jun 28, 2011 21:46:09 GMT

Hi Pete,

It does get a bit mesmerizing doesn't it? We had friends over for lunch yesterday and guess what they had to watch? At least it was a change from pics of the grandchildren. ;D ;D ;D

Jim

|

|

Smifffy

Statesman

Rock'n'Roll!

Rock'n'Roll!

Posts: 943

|

Post by Smifffy on Jul 5, 2011 15:13:17 GMT

Inspirational stuff Jim. I'm a few weeks behind you on the middle cylinder of my Royal Scot. Pretty much all over the valve gear is done with the exception of the eccentric rod and the reversing gear.

The latter I don't really need to do to get it to run, but it's a great excuse for not getting my head around the joys of the Walschearts!

Smifffy

|

|

|

|

Post by Jim on Jul 6, 2011 0:43:41 GMT

G'day Smifffy, Just been looking at your web site Smifffy, now that is inspirational. The Royal Scot is a beautiful loco and in the crimson livery will look spectacular, not that I am biased in any way as a MR, LMS fan.  As you might have gathered I have had a bit of a head ache getting my mind round how I should tackle the valve settings but I think I now have that sorted  I dips me lid to you for tackling a three cylinder loco with all the extra complication of the third cylinder's valve gear to machine. I'm still picking steel splinters out of my fingers  Jim |

|