Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Oct 28, 2013 22:16:30 GMT

So we can let Geoff's Clan build consented on building a Clan I thought I'd open this. Ejparrot wrote

Have you looked at the Doug Hewson design of pump as used on his Y4 and Standard 4? Pretty sure its been published in EIM. It uses O rings and spacers to set a rate of oil flow, and can be set down to virtually zero, but it's not done by the mechanism, so you don't get the issue of the lubricator not pumping when well notched up because there isn't enough travel on the ratchet. I've not built one or used one yet, but I'm intending using the deisgn for my Manning Wardle.

The key bit in there is it uses 'O rings and spacers to control the oil flow' How? I assume that they go just above the ball to increase /reduce the distance the ball is pushed off its seat and therefore control the oil. ? Is that right

Regards,

Andrew

|

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Oct 28, 2013 22:37:36 GMT

hi andrew,

ive only built one mechanical lubricator for my own locos (my first) all others having hydrostatic lubricators, but ive built a few for friends etc. after the first steam up of my first loco i took the LBSC type lubricator off and sleeved the ram bore down to 1/16" dia from 1/8" dia, and made a new ram.

the roller clutch version ive made a few of, and this does away with the problem of the lack of movement on a traditional ratchet type mechanical lubricator.

cheers,

julian

|

|

|

|

Post by houstonceng on Oct 28, 2013 23:16:25 GMT

Quote "Doug Hewson design of pump". Unquote

First published in EIM by Jim Ewins and copied by Doug et al.

|

|

|

|

Post by Deleted on Oct 29, 2013 0:20:16 GMT

Andrew, The ram on the Ewins pump doesn't seal until it enters the first O ring and it then only pumps the quantity of oil held between the two O rings. Changing the spacer between the rings and hence their distance apart alters the amount of oil between them and the amount pumped. Note that if you change the thickness of the spacer between the rings you also need to change the spacer above the top ring to compensate. I've made a few of these and they work very well. Jim reckoned that you didn't need a second clack valve with his design but I always fit one 'just in case'. The lubricators fitted by Modelworks and now supplied by Steamfittings etc. are also of the Ewins type.  Jim described the lubricator as part of his series of articles on Loadstar - his experimental 2-10-0 - in 1982. |

|

Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Oct 29, 2013 4:50:18 GMT

Baggo hi

So the end ram at the top of its stroke is above the top O ring I assume? The ram on the ones i have are returned by a spring not a captive pin and it is strong enough to push the ram up (once round far enough) and the clutches then release allowing the mechanism to freely rotate to its top position

am just trying to understand these lubricators.

|

|

|

|

Post by flyingfox on Oct 29, 2013 8:03:42 GMT

greetings, I too have built several of these Ewins designed lubricators, and they are very reliable, although, like "Baggo", I use a second inline check valve.

I would recommende the use of a scotch crank to drive the ram, rather than using a spring to push the ram up, when I did used a spring, it gave problems. Also, the spring puts more load on the drive mechanism, possibly leading to unreliable operation.

All that said, I still prefer hydrostatic lubrication.

Regards

Flying Fox

|

|

|

|

Post by ejparrott on Oct 29, 2013 8:56:26 GMT

Dodgy memory...I remember Doug saying it was someone else design...thought it was Ron Brays though....my dodgy memory..that's definitely the one!

|

|

|

|

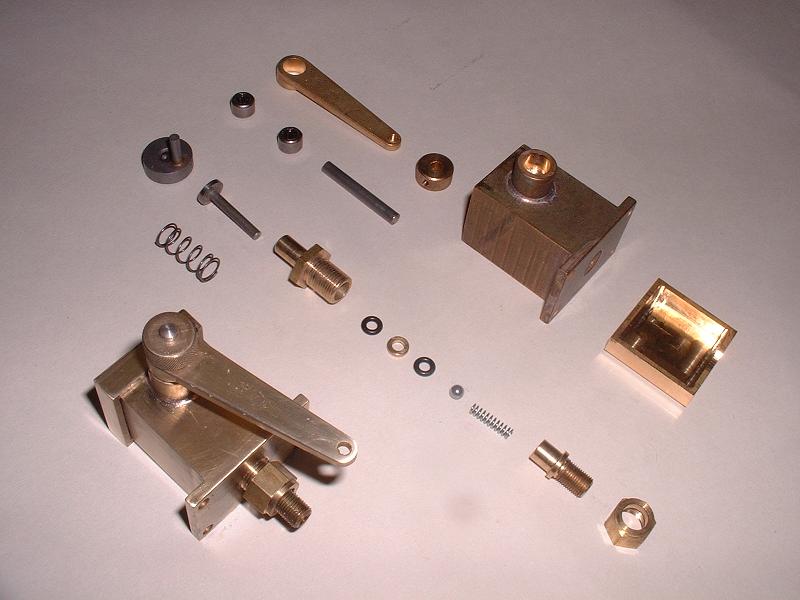

Post by Deleted on Oct 29, 2013 9:20:19 GMT

Hi Andrew Here's a photo of the components of the Steamfittings lubricator in our Modelworks Britannias. There isn't a spacer above the top O-ring in this case.  What I find surprising is that the thick steam oil can flow sufficiently quickly into the space between the O-rings when the plunger rises and before it comes down again. I suppose it's the vacuum created in that space that does it. My lubricators deliver rather too much oil when the lever is set to give the shortest reliable movement of the roller clutches (any less movement and the inner clutch can slip back enough to prevent the pump going over the top of the stroke) so I suppose I ought really to fit a thinner spacer. Regards, John |

|

|

|

Post by Deleted on Oct 29, 2013 10:11:29 GMT

So the end ram at the top of its stroke is above the top O ring I assume? The ram on the ones i have are returned by a spring not a captive pin and it is strong enough to push the ram up (once round far enough) and the clutches then release allowing the mechanism to freely rotate to its top position am just trying to understand these lubricators. Yes, the end of the ram is above the top O ring at the top of the stroke allowing oil to flow between the O rings. The length of the ram should be such that it just pushes the ball off it's seat at the bottom of the stroke. That's the problem with the spring return plunger - you can get more than one pump stroke per swing of the operating lever which increases the output from the lubricator. As mentioned, the scotch crank method of driving the ram is a better option although a little more difficult to make. I've got a copy of Jim's article on the pump if it would be of any help. John |

|

|

|

Post by ejparrott on Oct 29, 2013 17:06:21 GMT

Please

|

|

|

|

Post by Deleted on Oct 29, 2013 19:55:36 GMT

Let me have your email address (via pm or email to me) and I'll get a copy to you.

John

|

|

Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Oct 29, 2013 20:53:04 GMT

Hi John

Just sent you a pm. Yes I would love a copy please

Andrew

|

|

Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Oct 31, 2013 22:05:25 GMT

Ok. Having read the article by Jim ewins that baggo has been talking (thanks by the way) I now feel happier about this type lubricator.

My remaining concern focuses on reliability or rather being aware if its gone wrong. With one unit the feel of the soot in the chimney changes. With two as fitted to the Clan and Brit I don't think you will notice. Is that the case? Or do they never go wrong?

|

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Oct 31, 2013 23:27:47 GMT

andrew,

if properly made and tested they never go wrong!

cheers,

julian

|

|

|

|

Post by Deleted on Nov 1, 2013 9:39:06 GMT

Hi Andrew

It's worth replacing the spindles with 4mm hardened silver steel - this reduces the risk of the clutch slipping back before it bites. Also don't overfill the tanks, otherwise the oil can be pushed over the top of the tank by the motion of the crank and can get onto the clutches, which will cause some backslip before they bite. You can see when driving whether the knurled end caps are rotating fully. If they are, and if there's oil in the tank, then it will be getting to the cylinders (assuming that you've tested the pump initially, ie that the oil level goes down and isn't leaking out of faulty pipework).

I find that the biggest problem now is remembering to refill the tanks before they empty - I can only drive a couple of miles on a tankful. I'm thinking of increasing the tank capacity substantially by soldering a 2" or 3" length of 1/2" or 3/4" square brass tube to one side of the tank so that it extends along under the running board either in front of or behind the lubricator. I think it would be hardly visible and would hold enough oil for a day's running.

Regards, John

|

|

Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Nov 1, 2013 10:40:53 GMT

andrew, if properly made and tested they never go wrong! cheers, julian That's ok for one you have made yourself, These however if you look at the Photo JJ posted these have a potential hidden failure point in that the crank is held on the drive shaft by a grub screw. there is the potential for it to slip. I know because that's what happened to one of them the knurled wheel was going round and theer was no oil to one side and over winter a stuck piston  (Hence all this and other discussions) JJ. Yes john I was thinking the same thing about the tank size hence my comments on Geoff's Clan build. I will certainly enlarge them to the dimension Geoff is using and had thought of , as you said was thinking to extending the tank up under the running board or against the frame towards the cylinders. If I mess around with the size tank I might as well give my self a much bigger one. these current ones are 20x20x25 internal and are wholly inadequate. But that's my opinion based on other engines that have smaller cylinders and bigger tanks. My personal feeling is you need a tank(s) that you can fill at the beginning of the day and then top up once if needed, not every 15 minutes. But that's just me. Regards, Andrew |

|

|

|

Post by Deleted on Nov 1, 2013 11:21:50 GMT

Hi Andrew

Yes, I'd forgotten - I had the same problem with the crank coming loose on the spindle. I filed a deep notch in the spindle to stop this happening again. I also fitted an O-ring on the spindle between the crank and the inside of the tank body and nipped it up gently. This provides enough friction to stop the spring flicking the crank back on the return stroke, so that it is driven back by the clutches, and thus reduces the delivery rate to the same as the 'scotch crank' design. It may also reduce the risk of oil seeping through onto the clutches.

Regards, John

|

|

Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Nov 1, 2013 17:14:05 GMT

Thanks for that john. A good idea.

Andrew

|

|

Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Nov 1, 2013 17:20:31 GMT

Quote "Doug Hewson design of pump". Unquote First published in EIM by Jim Ewins and copied by Doug et al. Think I ought to point out I did already know this so I'll put it down to a senior moment  It was one of those I had my finger holding the mouse click on the send as I realised too late. Regards, Andrew |

|

Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Nov 2, 2013 16:29:51 GMT

I have just taken the lubricator that was not working are a few bite missing! Like two o rings and a spacer!!! I'll have to go back to the other house where my Workshop still is and have a hunt round. The bits must be there someplace Andrew Attachments:

|

|