|

|

Post by springcrocus on Jun 30, 2015 7:56:00 GMT

It's nothing you said, Brian, you might recognise the style of writing (Red Dragon or Pro999 whatever). The slightest criticism and he chucks the towel in, deletes his account and pops up a few days later with another account. I think we are up to five now. All rather ridiculous, I fear.

Good to see it all coming together, you've persevered a long time with your boiler and I, for one, have noted lots of things to look out for when I get to a similar stage on my own build. It's a brave man who doesn't try to hide his mistakes and/or errors so that others may learn. I take my hat off to you.

Steve

|

|

|

|

Post by ejparrott on Jun 30, 2015 8:32:10 GMT

The ashpan shouldn't be on the inside. Anything inside restricts the available area for combustion and aids the retention of ash. It should be outside or bolted up to the bottom, and ideally it should be a good fit, not a loose fit. If it's a loose fit, then air will leak in all around it, and your dampers will not be as able to control the fire as they should be. I've not got warped ashpans on any of my engines.

|

|

|

|

Post by GWR 101 on Jun 30, 2015 18:50:59 GMT

Hi Brian, sorry to hear of the problems you have encountered with your ash pan, I know it's probably not much consolation but I am on Mark 3 for a simple design engine and none of them have been near any coal yet. As much as I have great admiration for the designer I wonder if the ash pan was more of an afterthought. My drawings even have two different designs on the same set of plans. Mark 1 being a straight downhill taper from front to back, this was soon consigned to the scrap bin when I was informed this would be frowned upon as it would deposit ash onto the track. Mark 2 was a flat bottomed closed front, which was so deep (to drawing) it fouled the axle pump eccentric. Mark 3 my design was a combination of both, a sloping front half and level back. Even this had to be modified with a domed central portion to clear the eccentric when the suspension is loaded, and I still don't know if this will work. It is still to be finished so it's anybody's guess what the final one will look like wishing you good luck with yours, regards Paul

|

|

|

|

Post by ejparrott on Jun 30, 2015 20:52:40 GMT

All miniature ashpans will at some point drop ash on the track. We generate more volume of ash than scale. Having proper working dampers helps to alleviate the problem.

|

|

|

|

Post by runner42 on Jun 30, 2015 23:15:23 GMT

Thanks for your replies, I suppose it is important to understand the design criteria of the ashpan in a locomotive. It appears that apart from the drafting capability that the ashpan provides it must be able to be readily dropped for cleaning purposes and more importantly to drop the fire when there is an emergency due to a low water level in the boiler. So pulling the pin so to speak should see the ashpan drop at the front and slide off the rear retaining bracket when full of hot burning coal. How many builders have demonstrated this point?

Based on this safety point I would have thought that the code would have addressed this issue but it doesn't.

Coming back to LBSC's design and I don't think this problem relates solely to Doris, but many model locomotives, is that the design is a compromise. Many Doris locomotives have been produced and it doesn't appear to be an issue, LBSC has been vindicated by this. It clearly cannot be situated on the outside of the boiler because it appears to foul the hornblocks, perhaps.

If anyone can suggest an alternative design I would welcome their input.

Brian |

|

|

|

Post by Deleted on Jun 30, 2015 23:51:45 GMT

Brian, I've come up with a design for the ashpan on several of my 2½" gauge locos that are a bit different to the norm. I make the sides of the ashpan fixed to the chassis and just have the bottom removable.  The fixed ashpan has a 'cover' over the axle to try and keep grit etc. away from the bearing surfaces. Also, the ashpan can be made as deep behind the axle as in front of whereas the LBSC design is very shallow and will soon allow ash to block the rear section of the grate. The grate is hinged in the middle or thereabouts and the front half drops down to dump the fire when necessary. It's normally held up by a support fitted to the removeable ashpan bottom.   The only problem with the ones I've done so far is that the grate sits on top of the fixed sides of the ashpan and can only be removed by removing the boiler. That's not been a problem so far as it's not been necessary to remove the grate once fitted. I had a similar problem to you with clearance between the horns on my Helen Long so made a 'joggle' at the top of the ashpan sides so they still fitted on the outside of the inner firebox wrapper.  You might get some ideas form this? Hope the above makes sense. I've been out in the sun all afternoon and probably suffering from sunstroke! John |

|

|

|

Post by GWR 101 on Jul 1, 2015 7:46:12 GMT

Hi Brian, yes I was concerned about the need to drop the fire both in an emergency and at the end of running. I am unsure about which end is best to drop, but on mine the end nearest the cab falls down when the single pin that passes through the tube in the ash pan is withdrawn from the side of the engine. This is because I believed it was LBSC's proposed method and also the axle pump is in the way at the front end. The grate which is not shown in the previous photo sits on top of this tube and a stainless rod at the front of the ash pan (nearest the smoke box end). When the ash pan swings down the grate slides out towards the rear of the engine. The ash pan fits outside the inner firebox wrapper which projects down into it by about 1/4" (6 mm.) which I assume is to prevent side drafting, however the grate is mounted so that it is up inside this wrapper by about 1/8". I am unsure if this height of grate is correct and the proximity of the fire to the inner wrapper, but I believe I can easily alter this by adjusting the bottom of the grate. Hope this helps rather than confuses regards Paul.

|

|

|

|

Post by Deleted on Jul 1, 2015 8:32:30 GMT

Well - Springcrocus and all the other geniuses on this forum . You had your collective wish and I left . It was nescessary for me to re-register temporarily to contact a few people privately and system would not let me have my previous user names back hence the several changes .

I don't think you yet understand why so many people besides me have left this forum and you probably never will .

MichaelW

|

|

|

|

Post by springcrocus on Jul 1, 2015 14:31:26 GMT

Six.  Steve |

|

|

|

Post by Cro on Jul 1, 2015 15:07:20 GMT

John,

I love the idea for an ash pan and will show this to my Dad later who is doing a 2 1/2" Black 5. Its a great way of getting round the issue of the rear driving axle under the firebox. On my 5" Black 5 the two grate sections slide out the back under the foundation ring after you lift the cab floor up with a fixed ashpan like you have done here.

Adam

|

|

|

|

Post by Deleted on Jul 1, 2015 23:08:12 GMT

Hi Adam,

I should have recognised the surname as your Dad has been a member of the N25GA for some time now. It will be good to see another 2½" B5 as they seem to be quite rare. I've only seen one complete and running and one almost finished. Apologies to Brian for deviating from his thread.

John

|

|

|

|

Post by runner42 on Jul 1, 2015 23:12:57 GMT

Hi John,

thanks very much for your alternative solution, it is pushing the envelope so to speak. I like the idea of having a good depth of ashpan behind the trailing driven wheel, the point that you raise indicating the shallow depth is a candidate for clogging the grate is something obtained from experience, which you certainly have. I shall adopt your solution and it appears that others have seen the benefit of it, so it is reaching a larger audience.

Steve, thanks for sharing your experience and the manner in which you are solving your problems with your ashpan. You obviously considered the ashpan and grate as a more important item than I first did. It is something that is easily overlooked and not just a collector of waste products from the fire.

Brian |

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Jul 3, 2015 0:04:19 GMT

i think john has it spot on. in 32 years ive never had to drop a grate in an emergency, as have never had an emergency. ive often had to clear out the restricted sides of wide grates with the air line after a steam up, and i strongly approve of john's general ideas of having adequate space underneath all parts of the grate. this ensures good draughting with starts at the grate and ashpan and ends in the smokebox and petticoat pipe/chimney.

ashpans and grates are difficult for designers to draw. often a bit of thought and improvisation can substantially improve on ashpan and grate design. doubletop has shown this with his Simplex as have many others. there is usually a lot more room than appears on the drawings for these parts.

cheers,

julian

|

|

|

|

Post by 4fbuilder on Jul 3, 2015 15:33:52 GMT

Good afternoon folks,

A quick tip, should you ever get into the position where there is a need to drop the grate, not always the most convenient thing to do when halfway round the track, the quickest and simplist way to put the fire out is to stuff a piece of rag down the chimney and open the blower, it'll snuff the fire out immediatly, almost like turning the light off!

Regards,

Bob

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jul 3, 2015 20:53:09 GMT

Bob, Brian

Shut the fire door before turning on the blower and then only crack the blower open; it certainly does kill the fire.

Always carry a piece of rag with you.

Ian

|

|

|

|

Post by Shawki Shlemon on Jul 4, 2015 8:40:38 GMT

julian said - to stuff a piece of rag down the chimney and open the blower, it'll snuff the fire out immediatly, Read more: modeleng.proboards.com/thread/9668/lbscs-doris-code?page=16#ixzz3euTeSD2nIn ch 9 of the AMBSC code it say blank the chimney and open the blower to kill the fire . This is simple , the steam from the blower goes back through fire tubes into fire box and kill the fire , it has similar effect as fusible plug . |

|

|

|

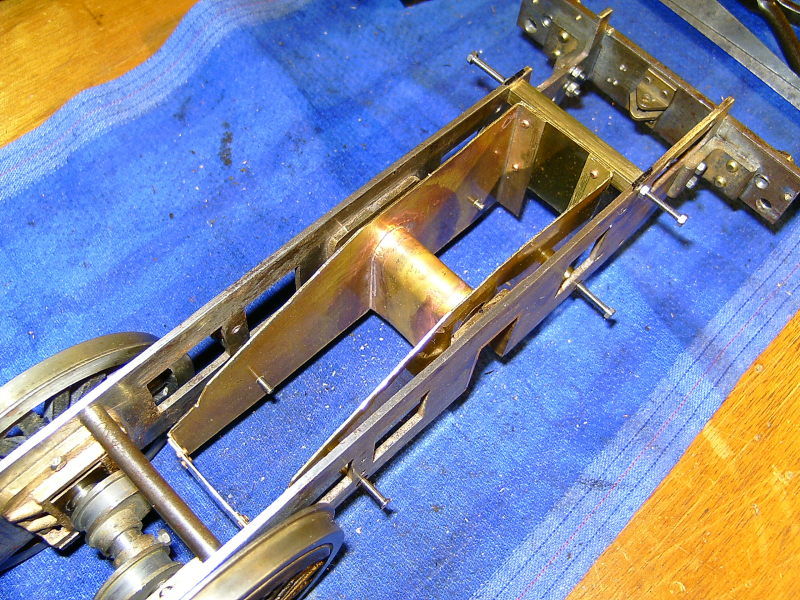

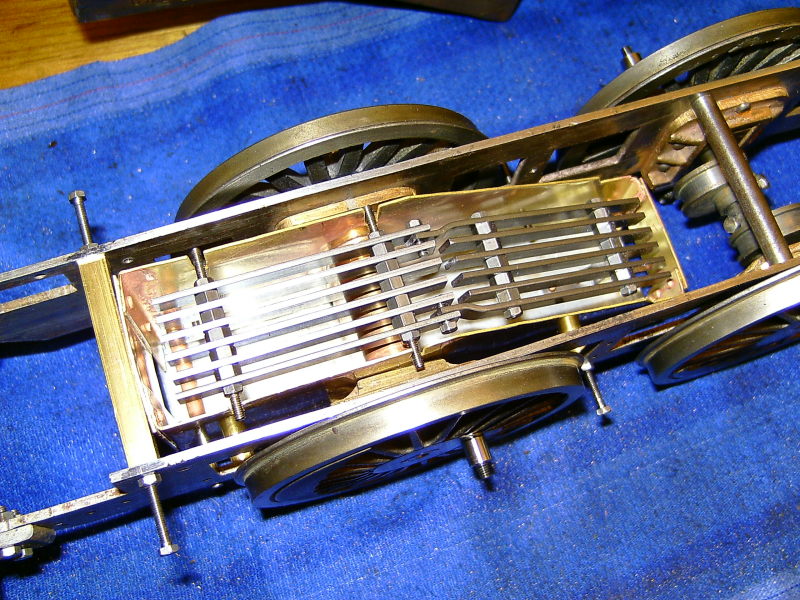

Post by runner42 on Jul 7, 2015 7:57:05 GMT

Just a photo shoot of Doris to show progress. However, I would like to get some advice on cleading Doris's boiler. I have purchased thin brass sheet to apply in two parts one to the barrel and the other to the Belpaire firebox. The barrel I assume would be straightforward but the Belpaire firebox has some special requirements, the main one being the transition of the barrel and Belpaire firebox. Is this produced similar to the flanged plate in that position for the boiler? The other is how is the brass fixing straps terminated at the bottom of the Belpaire firebox?

Brian

PS The number I have chosen for my Doris is 45747, this is derived from at age 45 I ran a 2hr 35min marathon and my race number was 747. Like the aircraft I knew on the day I was going to fly.

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jul 7, 2015 8:07:03 GMT

|

|