paul63

Involved Member

Posts: 65

|

Post by paul63 on Sept 5, 2014 8:47:48 GMT

Hi Guys,

Does anyone have a drawing of a screw type regulator which could be fitted to a 3.5 inch gauge loco. The tiny disc type don't seal very well. The boiler inspector does not like the regulator leaking a bit so I will try a screw type. I made one for a american loco years ago which worked well that was in the smoke box.

Regards

Paul

|

|

|

|

Post by Roger on Sept 5, 2014 15:06:30 GMT

There was a thread a while ago showing different materials and designs for disc types that overcame the leaking problems. I'm new to the subject so I can't add any more than that.

|

|

|

|

Post by digger on Sept 5, 2014 16:08:29 GMT

Paul63

With regards to the boiler inspector not liking the regulator leaking, I always put a blank in the main steam pipe to the cylinders as most regulators will pass a certain amount of water when undergoing a hydraulic test (the exception being the screw down type)

The disc in a tube regulator will seal when there is steam pressure on the disc, blanking off the main steam pipe to the cylinders serves the purpose of putting the super-heater elements (if fitted) under test also which can't be a bad thing.

Digger

|

|

|

|

Post by tractionbob on Sept 5, 2014 21:20:19 GMT

Hi Paul

I dont know on what 3.5 loco you are looking to replace the disc in tube. Some time ago I wanted to do the same on my 3.5 Juliet. A regular contributor on here, Baggo, sent me a drawing of one had had used on a loco, which I was able to modify to suit. I you give me your email address I can send you the drawing and it may be helpful as I am sure he wont mind me sharing.

Cheers

Bob

|

|

|

|

Post by Deleted on Sept 6, 2014 0:54:20 GMT

Hi Bob,

No problem, feel free to pass on the drawing. I can't remember which one it was but was probably the one for Helen Long?

I've made a couple more similar ones recently for two Tich boilers. The regulator for Martin Evans's Simplex is also a screw down type that could be scaled down. I prefer to use the bearing grade PEEK seats as they don't leak or seize up if you don't loosen them off when the boiler cools down. You actually need very little movement of the regulator handle to get enough steam flow. The one on Helen only needs to be barely cracked open for normal running.

John

|

|

|

|

Post by AndrewP on Sept 6, 2014 23:10:35 GMT

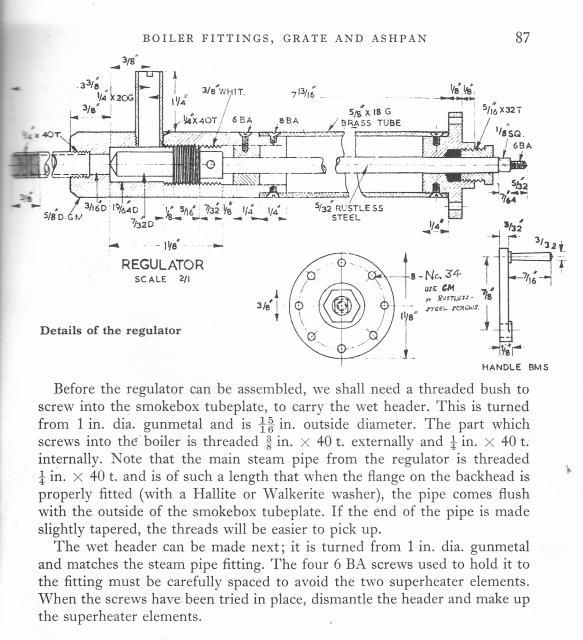

Paul try this:-

I admit I cheated and cut down a 3/8 Whit stainless bolt in mine because I didn't have a die.

Andy |

|

|

|

Post by Deleted on Sept 7, 2014 6:53:37 GMT

Personally I would have thought that including the super-heater element in the test was indeed a desirable thing to do....especially if said element is of the radiant type .........

|

|

paul63

Involved Member

Posts: 65

|

Post by paul63 on Sept 7, 2014 9:13:40 GMT

Hi guys

I would like to thank Bob and Andy for drawings and info you have saved me a lot of time sorting out this regulator. I will try to post some pictures of the finished parts which may help some one else.

Regards

Paul

|

|

|

|

Post by digger on Sept 7, 2014 9:19:11 GMT

Personally I would have thought that including the super-heater element in the test was indeed a desirable thing to do....especially if said element is of the radiant type ......... Yes it is, and I believe it's going to be introduced in to the test proceedure soon. Digger |

|

|

|

Post by GeorgeRay on Sept 7, 2014 17:12:05 GMT

It is included as part of the current procedure. However it is permissible to carry out the test without including the superheater providing the certificate is annotated that it was not tested.  |

|

|

|

Post by donashton on Sept 7, 2014 19:04:27 GMT

Before tests were done on the present basis (ie. necessary for insurance) an individual generally did his own test, THE OBJECT OF WHICH WAS TO SEE IF IT LEAKED and not to verify safe use!

That is why current association/federation tests are VERIFYING SAFE WORKING, and leakage is immaterial unless it prevents the structural test or is thought to warrant deeper investigation.

Testing superheater pipes and connections is a LEAKAGE test (as it is in FS), so must be done outside the boiler otherwise one cannot see the points of leakage!

Don.

|

|

|

|

Post by Deleted on Sept 7, 2014 22:00:51 GMT

Before tests were done on the present basis (ie. necessary for insurance) an individual generally did his own test, THE OBJECT OF WHICH WAS TO SEE IF IT LEAKED and not to verify safe use! That is why current association/federation tests are VERIFYING SAFE WORKING, and leakage is immaterial unless it prevents the structural test or is thought to warrant deeper investigation. Testing superheater pipes and connections is a LEAKAGE test (as it is in FS), so must be done outside the boiler otherwise one cannot see the points of leakage! Don. -------------------------------------I'm assuming ( rightly or wrongly) that an individual will do a "pre-test" on his boiler BEFORE presenting it to the Club Inspector... Much the same way as you'd get your car Pre-tested ( or at least checked-over before it's MoT )...................So, will our friend PAUL's regulator also come within the scope of a Boiler test ??... After all, a badly leaking regulator is as much undesirable/unsafe as the aforementioned Superheater elements................ANDY, that's not "Cheating" matey, that's good old Engineering "improvisation"----------BUT !!! }----- Is the S/S bolt material up to the standard require for operating within a boiler environment ?........... I recently acquired a "Cheapish" SIMPLEX with a seized regulator...... After how shall we say ?-- "Extraction" it was found to be rusted solid !!---- Someone had used mild steel for ALL the construction....................Here's a photo of another regulator where I suspected that all was not as claimed !!------ After literally an ACID TEST the operating rod rusted whereas the screw down nose didn't... That's why I bent the rod ie}--- to prevent me doing a "Quickie" repair..........Actually, if you can look closer, the nose seems to have some flecks of rust showing as well !!........  |

|

|

|

Post by Deleted on Sept 8, 2014 1:59:14 GMT

Alan,

It's amazing how many don't do a pre test check before presenting a boiler or complete loco for test. I carried out a steam test on a 3½" Juliet last Thursday and when I checked the gauge glass blowdown nothing came out when I opened the valve! The valve was completely blocked. Didn't take much sorting out but the extra hassle would have been avoided if the owner had checked beforehand. Did a few laps of the track to check the axle pump and the lubricator wasn't working either - the ratchet wheel wasn't going round!!

John

|

|

pondok

Part of the e-furniture

My 5" gauge SAR class 15F

My 5" gauge SAR class 15F

Posts: 359

|

Post by pondok on Sept 8, 2014 14:20:14 GMT

I would hope the superheaters would be tested separately from the boiler surely? otherwise if the superheater fails, you'd have to fail the boiler too, what with water pouring out either end, or both, of the superheater flues. If the boiler were sound, the paperwork could be done pending repair of the superheaters and the test wouldn't have been a waste of time... no? Same goes for commercial or newly built boilers, that are usually tested off the frames and unclad, simply plugged. Surely you wouldn't then have to halt testing until you'd made the superheaters?

|

|

pondok

Part of the e-furniture

My 5" gauge SAR class 15F

My 5" gauge SAR class 15F

Posts: 359

|

Post by pondok on Sept 8, 2014 14:21:47 GMT

|

|