|

|

Post by alanstepney on Mar 12, 2015 11:21:56 GMT

Additive manufacturing or 3D printing has moved on in leaps and bounds from what it used to be.

Whilst the hobby machines are still fairly basic, at the top end, some machines are doing fantastic work. (At a fantastic price, I might add!)

(Rolls Royce now produce jet engine parts this way.)

However, it probably wont be long before machines are available in "our" price range that can produce bits that will be suitable for our models.

Has anyone any experience of them, or any comments?

|

|

|

|

Post by Deleted on Mar 12, 2015 11:30:42 GMT

Have you read Adam Cro's thread on the Stanier brake valve?

|

|

|

|

Post by Cro on Mar 12, 2015 12:14:44 GMT

It really depends on what you want to do and what you want/expect the printer to do.

If you have seen my threads for the Brake Valve and the Scale fittings these have mostly been done with 3D printed wax. Using 3D printed wax it skips a few steps in the lost wax process allowing for either 1 off casts or complex castings including internal porting. BUT and the big BUT is that a printer that produces these waxes with such a high resolution is extremely expensive.

For simpler parts its fairly similar for castings, it comes down to the quality of the master model, price can go up considerably to get the quality

- example:

7 1/4" BR manifold, High Quality resin based print - £65

7 1/4" BR manifold, Low quality to see how the casting version would look - £12 (and it really was low quality)

It is definitely the way to go for high quality castings these days hence why I am venturing into this world.

Adam

|

|

|

|

Post by alanstepney on Mar 12, 2015 14:29:18 GMT

I see that some of the latest machines can print metal parts in stainless steel, bronze titanium and no doubt other metals.

I gather that these machines are still expensive, but no doubt will come down in price.

Printing the valve gear, or simple items such as the frames to go round windows, might be of use to "us".

|

|

|

|

Post by Cro on Mar 12, 2015 14:33:35 GMT

|

|

Tony K

Elder Statesman

Posts: 1,574

|

Post by Tony K on Mar 12, 2015 15:24:14 GMT

Would someone care to define what a 3D printer is?

I think a CNC mill or CNC lathe could be termed a 3D printer.

|

|

|

|

Post by alanstepney on Mar 12, 2015 15:40:31 GMT

A CNC mill or lathe SUBTRACTS metal from the original.

3D printing ADDS material, in some form, and just adds what is needed for the finished object.

(All as I understand it.)

The early 3D printers used a plastic of some sort, (with differing technologies) so that you ended up with a hard plastic item.

Now they can use metal.

|

|

NickM

E-xcellent poster

Posts: 230

|

Post by NickM on Mar 12, 2015 16:31:46 GMT

The current industrial buzzwords are Additive Manufacturing (3D printing in it's many forms) and Subtractive Manufacturing (milling, turning etc, CNC or not)

NickM

|

|

|

|

Post by Doug on Mar 12, 2015 16:39:31 GMT

(Rolls Royce now produce jet engine parts this way.) Has anyone any experience of them, or any comments? Funny you should mention that I work for a company that deals very closely with said company and the biggest 3D printed jet engine assembly in the world. I need to be careful what i say about it (obviously its secret IP) but needless to say it is an amazing part made from Titanium. tolerances are Areospace so um's. as for what 3D printing can do for us well lots and lots yes the machines are expensive and i doubt any of us will be buying a laser sintering machine anytime soon but its cheap and easy to get the parts made for us by companies like shapeways. |

|

|

|

Post by ejparrott on Mar 12, 2015 17:00:09 GMT

Funny you should mention that I work for a company that deals very closely with said company Not ITP or Florida Turbines by any chance?!! |

|

|

|

Post by Doug on Mar 12, 2015 17:58:16 GMT

Funny you should mention that I work for a company that deals very closely with said company Not ITP or Florida Turbines by any chance?!! No Winbrogroup but we do some work on the ITP parts that are then sent on to Rolls as well as the RR parts  |

|

|

|

Post by GWR 101 on Mar 12, 2015 18:02:19 GMT

Well there is no escaping this modern technology, this afternoon on CBeebies in the programme Nina and the Neurons they were describing how 3D printers work and showing examples. Just in case anyone is thinking what was I doing watching it, well I wasn't when it started my Grandson was but I was when it finished. What is it they say "Start them young" Regards Paul

|

|

|

|

Post by joanlluch on Mar 12, 2015 18:14:29 GMT

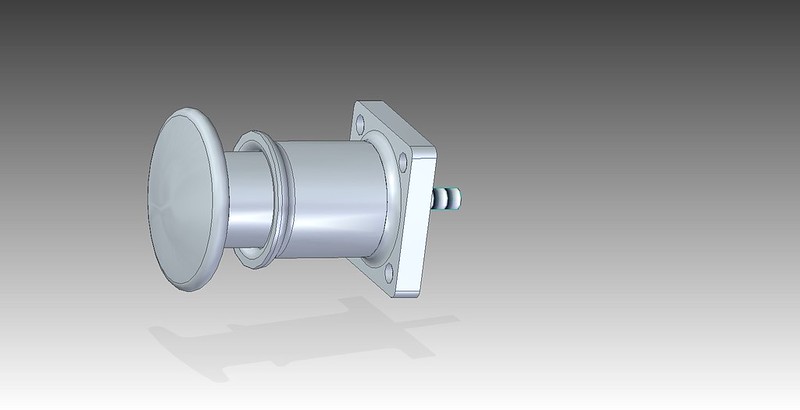

In my "lsfornells" thread I have recently posted my experience on making the front buffers using a local 3D printer service, but I didn't know about shapeways. These guys seem as really worth a try. This is how they compare with the service I used: Parts to print:  BufferAssembly BufferAssembly by joan.lluch, on Flickr Result (local company) (very bad resolution and expensive prices):  Buffer Buffer by joan.lluch, on Flickr Price for ONE of the above in white plastic from the LOCAL COMPANY: Buffer: 26.65 € Buffer Socket : 30.67 € Same from SHAPEWAYS in white plastic Buffer : 7.23 € Buffer Socket : 8.48 € Same from SHAPEWAYS in Stainless Steel Buffer : 46.35 € Buffer Socket : 46.84 € Interestingly, this is cheaper than CNC machining the same. For more complicated parts, CNC may be a lot more expensive, or even not possible. EDIT. Just noticed that prices from SHAPEWAYS already include VAT, so it's even cheaper than I thought |

|

bhk

Part of the e-furniture

Posts: 458

|

Post by bhk on Mar 12, 2015 18:33:24 GMT

Joan, those white things are done on a very very cheep printer indeed, something you could buy from a toy shop even!

Shapeways even at there lowest resolution will surpass them a million times over.

I can't actually believe a company has the audacity to charge for them!

|

|

|

|

Post by Cro on Mar 12, 2015 18:40:43 GMT

The White plastic from shapeways will be ALOT better than what you have there and would be usable from a casting point of view with a bit of a tidy up after, on our 3D printing facebook page there was a small story from someone who had used 3D metal printing in Matte Bronze Steel - this material is 420 Stainless Steel infused with bronze, and has a final composition of approximately 60% steel and 40% bronze.

A few snippets from it - "I destroyed 2 end mills"

"As far as drilling the pin holes - dulled the first centre drill then went to a larger one & used Defcon safe-tapping fluid to lubricate while drilling, standard milling coolant no go."

"it would be impossible to use a 1/16" slot drill"

He Concludes with

"This material is not really suitable for model engineering components - unless there is no machining to be done."

Just thought this would be useful info for anyone looking a metal printing, research into the end result is key!

Adam

|

|

|

|

Post by GWR 101 on Mar 12, 2015 18:43:47 GMT

Just seen a local TV news item, the Q.E. hospital in Birmingham are using one to make the formers for parts used in reconstructive surgery, they believe that in less than 5 years they will be able to directly produce parts. Regards Paul

|

|

|

|

Post by bobpendleton on Mar 12, 2015 18:49:49 GMT

(re Rolls Royce now produce jet engine parts this way - alan stepney.) I work for a company that deals very closely with said company and the biggest 3D printed jet engine assembly in the world. I need to be careful what i say about it (obviously its secret IP) but needless to say it is an amazing part made from Titanium. tolerances are Areospace so um's. as for what 3D printing can do for us well lots and lots... Some recent info at 3dprintingindustry.com/2015/02/19/rolls-royce-to-fly-largest-3d-printed-part-ever-flown/(I was looking for a report I thought was in a recent Telegraph newspaper or supplement but cannot now find it) bp |

|

|

|

Post by joanlluch on Mar 12, 2015 19:00:37 GMT

Joan, those white things are done on a very very cheep printer indeed, something you could buy from a toy shop even! Shapeways even at there lowest resolution will surpass them a million times over. I can't actually believe a company has the audacity to charge for them! Hhi bhk, Of course. Please read my thread, the case of the local company was already discussed thoroughly. |

|

|

|

Post by joanlluch on Mar 12, 2015 19:06:07 GMT

The White plastic from shapeways will be ALOT better than what you have there and would be usable from a casting point of view with a bit of a tidy up after, on our 3D printing facebook page there was a small story from someone who had used 3D metal printing in Matte Bronze Steel - this material is 420 Stainless Steel infused with bronze, and has a final composition of approximately 60% steel and 40% bronze. A few snippets from it - "I destroyed 2 end mills" "As far as drilling the pin holes - dulled the first centre drill then went to a larger one & used Defcon safe-tapping fluid to lubricate while drilling, standard milling coolant no go." "it would be impossible to use a 1/16" slot drill" He Concludes with "This material is not really suitable for model engineering components - unless there is no machining to be done." Just thought this would be useful info for anyone looking a metal printing, research into the end result is key! Adam Hi Adam. Of course the white printed parts I posted are awful. This was already discussed in my build thread. The parts I am posting as examples do not need machining, so my understanding is that they should be fine as delivered by shapeways. I mean directly printed in metal, such as Stainless Steel, not plastic. |

|

|

|

Post by Doug on Mar 12, 2015 19:25:44 GMT

That's ok then the cats out of the bag, yes the bearing housing is massive the vanes are 3d printed and then they are weled together to form the massive part we have machined all the 97k bearing housings (we put anti icing holes in the vanes) we also do a lot of the 87k engines too but these have been cast titanium, I think we have had about 3 off the 3d printed 97k ones they are ace makes you proud that a uk company is developing this technology. |

|