|

|

Post by terry1956 on May 17, 2015 8:26:30 GMT

Hi chaps,i am about to fit a new tender water valve.this is the long handle water injector 1/4 turn type. What is the best way to fix the handle into position. Michael

|

|

|

|

Post by digger on May 17, 2015 16:00:21 GMT

In my opinon they are best fixed on to a square section of the spindle, file or broach a square hole in the handle to suit a square milled on the spindle then hold with a washer and nut on a threaded portion of the spindle, above the square.

Digger

|

|

jj

Active Member

Posts: 47

|

Post by jj on May 17, 2015 17:05:37 GMT

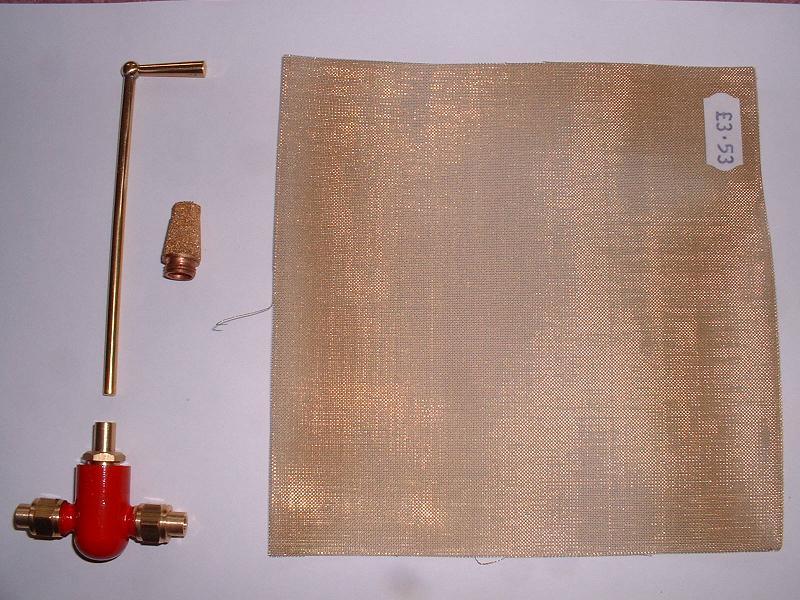

If it's this sort of valve which I have in my Britannia tender (I bought mine from Polly Model Engineering), I just used Loctite 638:   I think Digger is describing how you would fix the handle crossbar to the spindle, but in this case it comes in one piece. Regards, John |

|

|

|

Post by digger on May 17, 2015 17:22:41 GMT

I looked too deep for the solution, my thoughts were of good engineering practice... a positive drive that would not slip yet one that can be dismantled,

I can well see that in this application, loctite 63 would suffice.

Digger

|

|

|

|

Post by terry1956 on May 17, 2015 18:40:08 GMT

Thanks chaps7

|

|

|

|

Post by daveburrage on May 17, 2015 19:33:02 GMT

My suggestion

Make the square on the shaft slightly tapered and file so it goes about half way into the hole in the handle. When you tighten the nut it locks solid without the annoying slack you often get

regards

Dave Burrage

|

|

|

|

Post by trainman on May 17, 2015 20:14:50 GMT

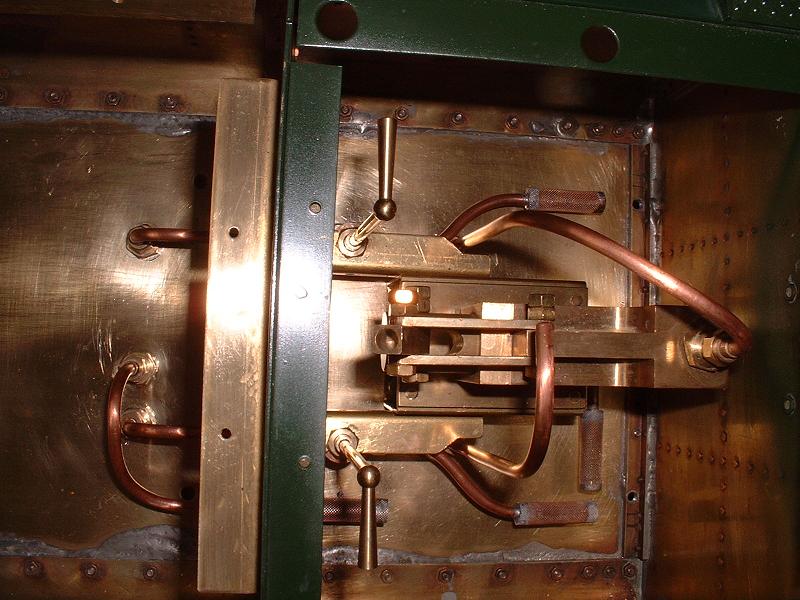

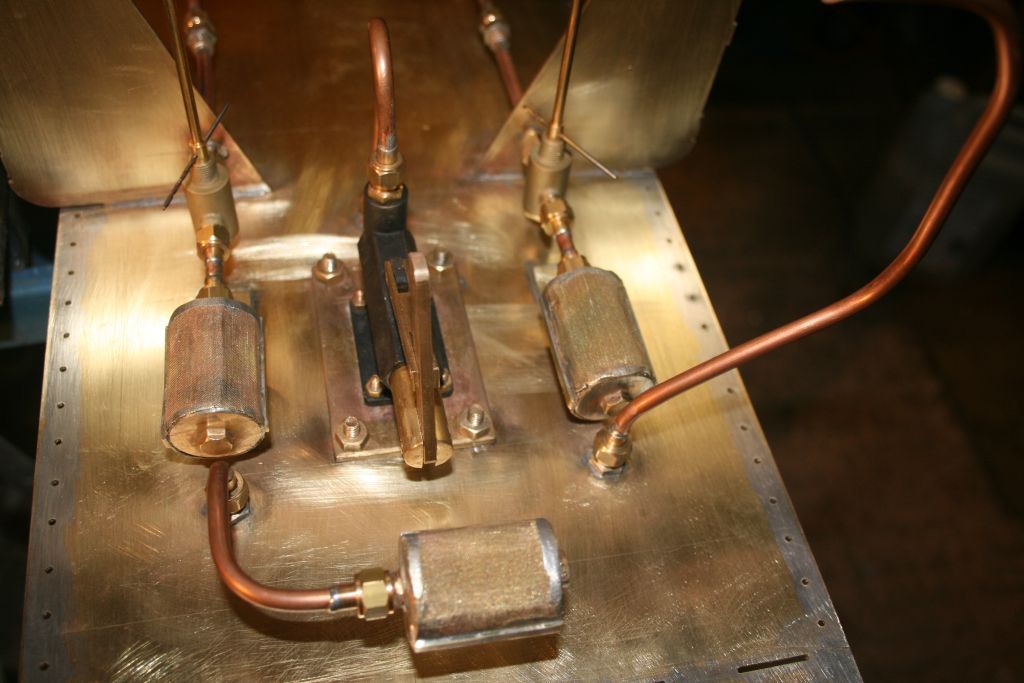

I wondered what to do here as well. In the end I drilled through the shaft/valve and put a brass split pin through so it could be dis-assembled if required. Paul (the drills were temporary!)  |

|