|

|

Post by simplyloco on Jun 8, 2018 10:15:50 GMT

|

|

abby

Statesman

Posts: 927

|

Post by abby on Jun 8, 2018 19:56:10 GMT

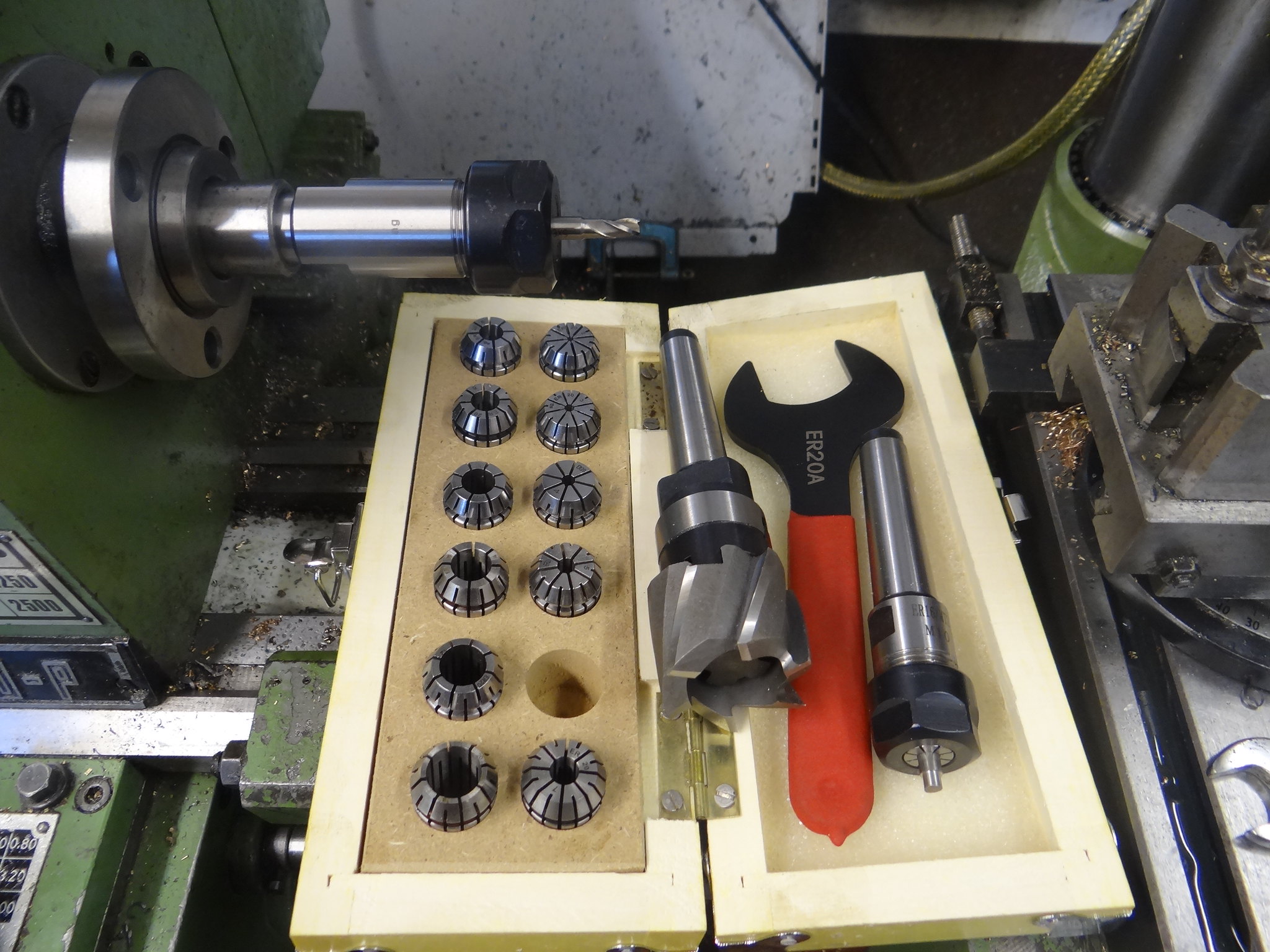

I made my own ER20 collet chucks for my BCA jig borer and Pultra lathes as none were available at the time,I bought mini nuts and spanners off Ebay

A complete set of ER20 collets I bought piecemeal from various on-line suppliers including Arc_Eurotrade.

I would guess that all of the parts were made in Asia but they have proved satisfactory to date.

Dan.

|

|

|

|

Post by jon38r80 on Jun 11, 2018 9:09:56 GMT

I have both ER25 and 40 chucks for both my Mill ( on MT2 shanks) and on back plates for work holding on the lathe instead of 3 jaw chucks (most things I make start life as a chunk of round bar). The chucks with back plates came from Arc and the shank mounted from different Chinese suppliers. The collets came from a variety of Chinese suppliers direct. Never had a problem with any of the separate bits but Im probabaly not looking for the same degree of accuaracy as you want for making engine parts. I haven't ever bothered to check the run out, they certainly hold drills much truer than any other chuck I have and hole sizes are pretty accuate as a result. Repeatability in the chuck is not an issue for me as I try to make things in one go without removing the workpiece from the chuck. I also found the Stevensons blocks I got from Arc very usefull for putting square or hex flats on things that started life as a round.

No association with any of the suppliers, I just look for the best value I can get.

|

|

|

|

Post by 92220 on Jun 14, 2018 9:36:44 GMT

Admittedly my collets are ER32 but the runout of a piece of 3/8" silversteel, in the collet chuck, in the 2MT vertical head, is only 0.0003" to 0.0005" T.I.R. which is as accurate as I will ever want. Set bought from RDG Tools.

Bob.

|

|

|

|

Post by simplyloco on Jun 14, 2018 13:25:26 GMT

Thanks for all your inputs. I bit the bullet (and my misgivings) and went the Chinese route. The ER20 chuck and collet set (£93) came from Germany in one week via China, and there is no runout on the arbor, and less than a thou on a 6mm end mill! The shell end mill (just £29.00!) does not run out at all, and after a tryout at full diameter on some mild steel it is terrific, but the the ER16 chuck (£7.99!!!) has 0.003" TIR, which I suspect is down to the collet. I'm now well equipped, well, the mill is... John  DSC00320 DSC00320 by inkaboat, on Flickr |

|

|

|

Post by 92220 on Jun 14, 2018 17:32:56 GMT

Hi John.

Check for tiny bits of dirt. I found you have to have the collets and chuck mating surfaces scrupulously clean. I've learned to blow everything out with the airline before fitting together, every time now.

Bob.

|

|

|

|

Post by simplyloco on Jun 14, 2018 17:51:19 GMT

Thanks Bob. I also clean up before assembly, but perhaps not well enough The mill chuck and the ER16 chuck lock up in the spindle, and I've had to make a wedge to remove them. They still need a tap on the ejector to get them out. In 55 years of lathe work I've never experienced this before. I've blued them in the bore and there might be a slight barrelling on the taper shank, but I'm stumped at the moment.

|

|