Post by springcrocus on Oct 20, 2020 22:42:01 GMT

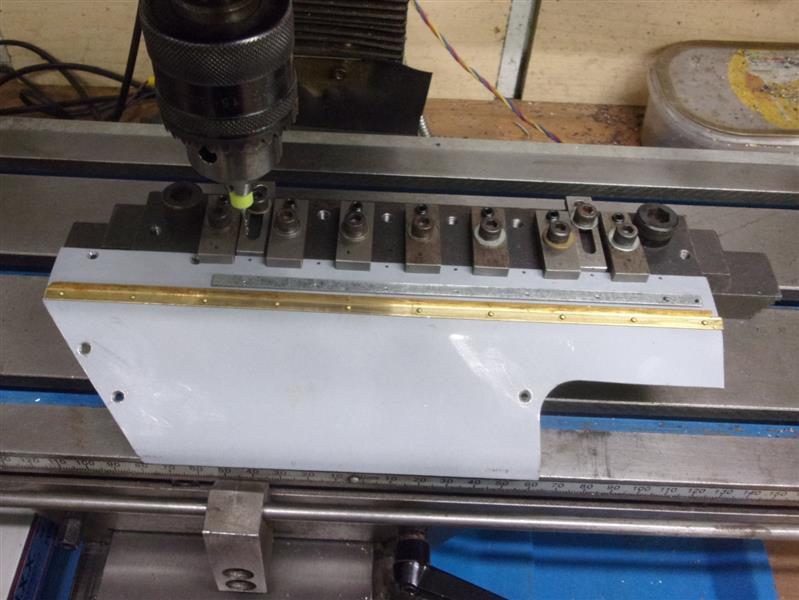

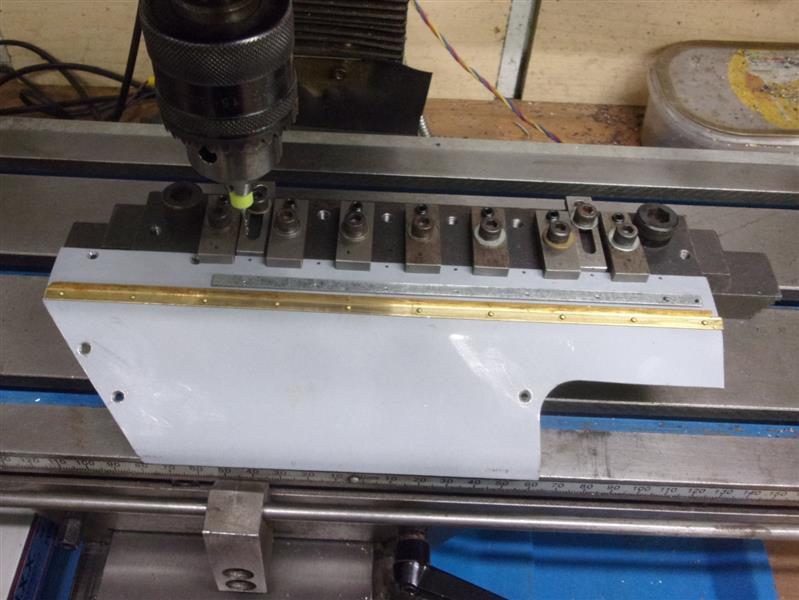

I needed to make a large quantity of thin strips and angles from offcuts of sheet steel but edge-milling vertically in a vice was never going to be a sensible option. I decided to invest a couple of hours in making a simple fixture for holding strips of steel and milling the edges true. It is only a simple clamping fixture but allows quick and easily repeatable operations. There was a 240mm length of 40 x 8 black steel in the scrap box and this became the body of the fixture. The edges were milled flat and true to create a clocking face.

A series of M5 holes were drilled and tapped at 1" spacings along the length for the clamps and another series half-way between them for the distance fingers. Clamps were made from 1/2" x 3/16" ground flat stock with 5.1mm holes for the clamp screws and M5 tapped holes for the packing screws, grub-screws in this instance. The distance fingers are from 1/2" x 1/8" BMS with a 5.5mm slot milled for most of the length. A pair of 11mm holes were drilled for fixing to the mill table. These four strips of 45 thou steel have been finished at 3/16" wide and are just under 7" long.

By adjusting the grub screws, any thickness of material can be easily clamped without the need for additional packing. The fingers can be adjusted with a vernier caliper before setting the jig on the table. The fixture can also be used for drilling holes in strips of metal, or angles, assuming spacings are correct for the job. Here, an end stop has been clamped into place and the strips rested against it.

I was also able to use the jig at the same settings for the roof that the strips will fix to by raising the jig on packing blocks. These are 1.2mm holes for 3/64" brass rivets. The gutter strips on the roof section were drilled with this fixture also.

The main advantage of the fixture, however, is the ability to true up thin strips using the side of the end mill rather than the end. The cutting forces are pushing into the fixture rather than at right-angles to it. And the multiple clamps when drilling prevent the thin sheet lifting up at drill breakthrough and raising a large burr on the opposite side.

A very simple piece of kit that took a couple of hours to make but well worth the time invested.

A series of M5 holes were drilled and tapped at 1" spacings along the length for the clamps and another series half-way between them for the distance fingers. Clamps were made from 1/2" x 3/16" ground flat stock with 5.1mm holes for the clamp screws and M5 tapped holes for the packing screws, grub-screws in this instance. The distance fingers are from 1/2" x 1/8" BMS with a 5.5mm slot milled for most of the length. A pair of 11mm holes were drilled for fixing to the mill table. These four strips of 45 thou steel have been finished at 3/16" wide and are just under 7" long.

By adjusting the grub screws, any thickness of material can be easily clamped without the need for additional packing. The fingers can be adjusted with a vernier caliper before setting the jig on the table. The fixture can also be used for drilling holes in strips of metal, or angles, assuming spacings are correct for the job. Here, an end stop has been clamped into place and the strips rested against it.

I was also able to use the jig at the same settings for the roof that the strips will fix to by raising the jig on packing blocks. These are 1.2mm holes for 3/64" brass rivets. The gutter strips on the roof section were drilled with this fixture also.

The main advantage of the fixture, however, is the ability to true up thin strips using the side of the end mill rather than the end. The cutting forces are pushing into the fixture rather than at right-angles to it. And the multiple clamps when drilling prevent the thin sheet lifting up at drill breakthrough and raising a large burr on the opposite side.

A very simple piece of kit that took a couple of hours to make but well worth the time invested.

Steve

Edit: I forgot to mention that the clamps are made to fit dead in line with the front edge, just like vice jaws. I've also made a pair of 3/32" wide strips on this fixture that don't vary more than two thou along a 6" length.