adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jan 29, 2021 9:45:09 GMT

? This locomotive was started by Jim Rees of Beamish Museum , county Durham. The frames, wheels and axles and eccentrics were taken over by Adrian Morley who completed the build. The boiler was made by Adrian Morley and Robin Hedley ( both members of the Beamish Model Engineering group). Additional work on the boiler was completed by Brian Nicols, Stuart Davidson and Ian Spencer ( members of the Tyneside Society of experimental and model Engineers , TSMEE). The entire project was spread over some 13 years. The locomotive was steamed an  d certificated in 2020. Shown above is the test on compressed air. The air compressor was originally used by Beamish Museum in firing full size locomotives by injecting air into chimney. The chassis is being painted during construction.

It is my intention to show stages of building and the construction of the boiler. This may take time until I have mastered the intricacies of this site. ![]() It was my general intention to complete this locomotive in the form which it might have been delivered rather than the locomotive which has evolved over the century on the Tallylynn Railway. The illustration of the general type shown has a flat appearance of the smoke box door which suggests it may have opened upwards. From practical experience I can say that this not only restricts access but also is dangerous unless properly secured.

Lock down in 2020 produced a radical change with confinement to the work shop the main benefit. As a result I have spent the best part of 2 years making DAG Browns injectors and testing them on my test rig.

but that will be a separate thread. As promised above here is the finished version of DOLGOCH

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 27, 2022 15:46:26 GMT

![]() Lock down in 2020 produced a radical change with confinement to the work shop the main benefit. As a result i have spent the best part of 2 years making DAG Browns injectors and testing them on my test rig. but that will be a separate thread. As promised above here is the finished version of DOLGOCH. After storing Dolgoch at Beamish for 5 years the closure of BMEG meant that I had to rapidly fing storage for three engines and a driving trolley. My neighbour constructed a sturdy platform in the carport adjacent to my workshop.Cobined with a hydraulic table this allows me to move engines into my van or workshop.An electric garage door provides security.

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 27, 2022 16:35:10 GMT

The locomotive has had a number of modifications, in particular modern twin safety valves which required a new dome cover. I have the originals but for show only. Initially I had problems with steam production. The firebox is very deep compared with my Wren although the grate area is similar. This was largely cured by drilling ten 3/8th holes in the ashpan. The ashpan was originally secured by six bolts into the foundation ring. Impossible then to drop the fire. I have replaced these with two stainless steel rods across the bottom of the ashpan which can be easily be drawn out after release from the threads at one end. Two injectors are fine but I felt safer with a substantial hand pump hidden in the main water tank.Also I can pass the steam test if one injector is on the blink. The draincocks were very close to the track and as a result were frequently damaged in transit, automatic drain cocks have been very successful , take up less room, and are easy to make.

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 28, 2022 10:29:22 GMT

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 28, 2022 10:36:48 GMT

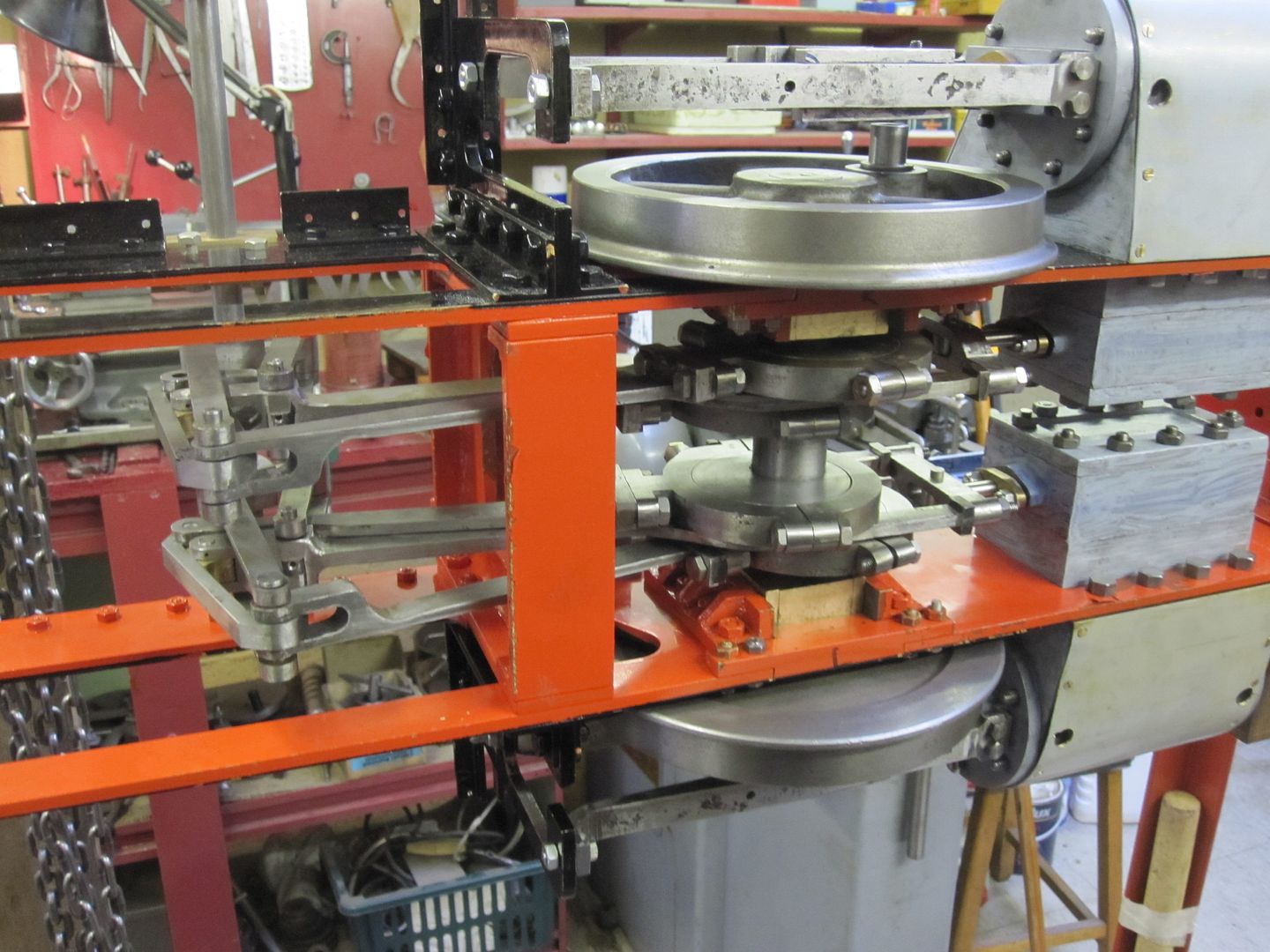

Dolgoch was built on the frame showm which allowed rotation. After completion of the running chassis and testing on air it was placed on a recycled hospital trolley and later transfered to a moveable hydraulic table. at an early stage I decided to prime and paint as I went along.

|

|

|

|

Post by Nigel Bennett on Jun 28, 2022 12:49:29 GMT

It's a big engine in 5"G, never mind 7.1/4"! You'd wrote that you had helical springs on it - and I wasn't surprised to read you'd done that as making volute springs as per the original would be difficult - but then I see from the photos that you had got the correct volute springs fitted - but what a crying shame they clobber the boiler so you can't use them!

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 28, 2022 17:04:13 GMT

I had them made by a friendly blacksmith. apologies for incorrect term. the back wheels use the volute springs.

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 28, 2022 17:28:06 GMT

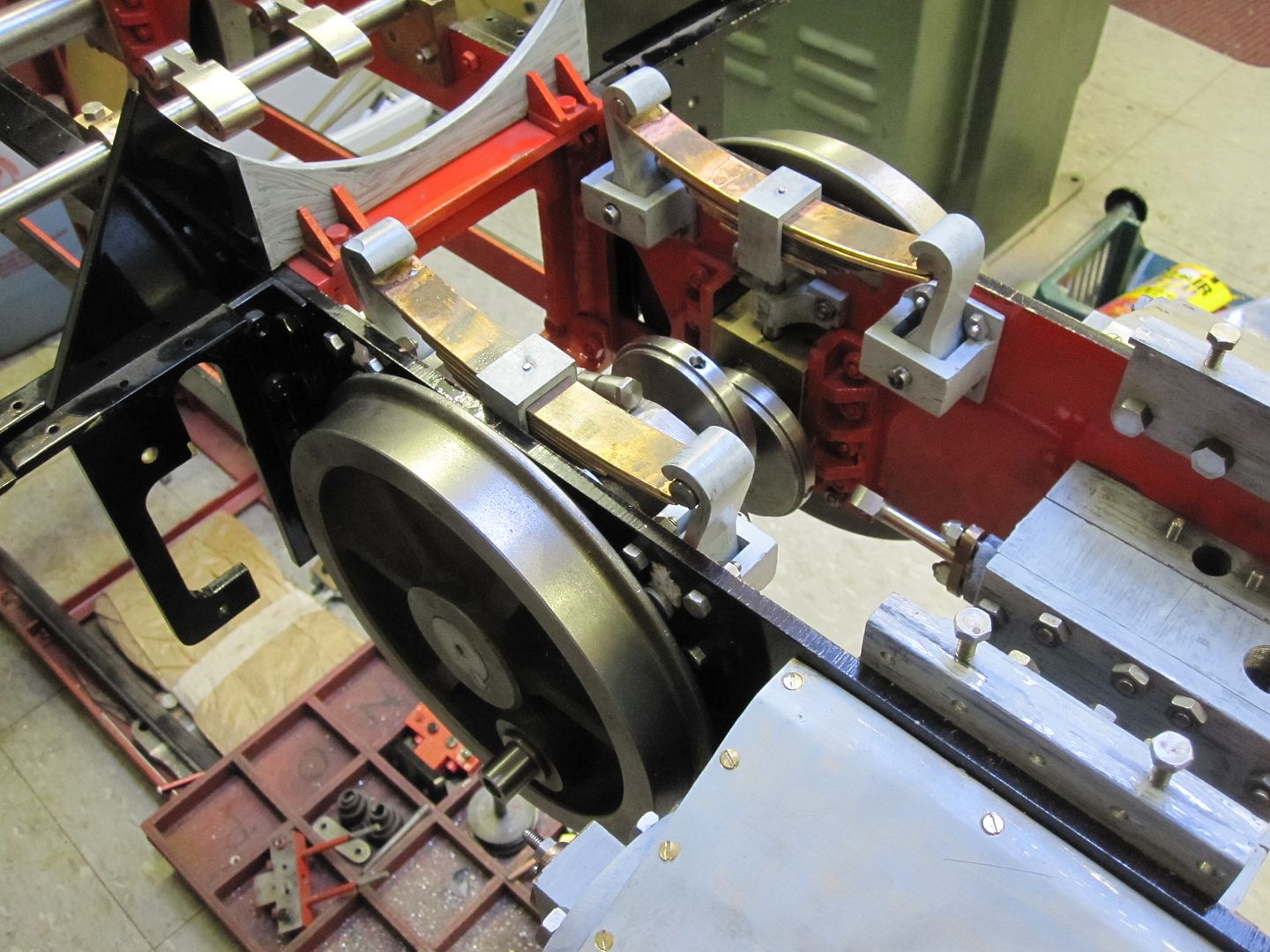

The next few pictures show stages of machining the the cylinder castings. I was fortunate to have a set of patterns produced for Jim Rees who started the loco. Hexham has a foundry which did the castings for me, I still have onbe spare.The foundry has been taken over by Anthony Gormley of "Angel of the north " fame, so its no longer avaidable

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 30, 2022 7:50:45 GMT

The circular table was used to drill round the cylinders. The Miller is an Elliot omnimill, originally owned by the department of medicine , University of Newcastle. By the 1970s the era of making your own research equpment was over. It was in mint condition and allows both horizontal and vertical milling. the three phase converter has now lasted some 20 years with problem.

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jun 30, 2022 8:23:06 GMT

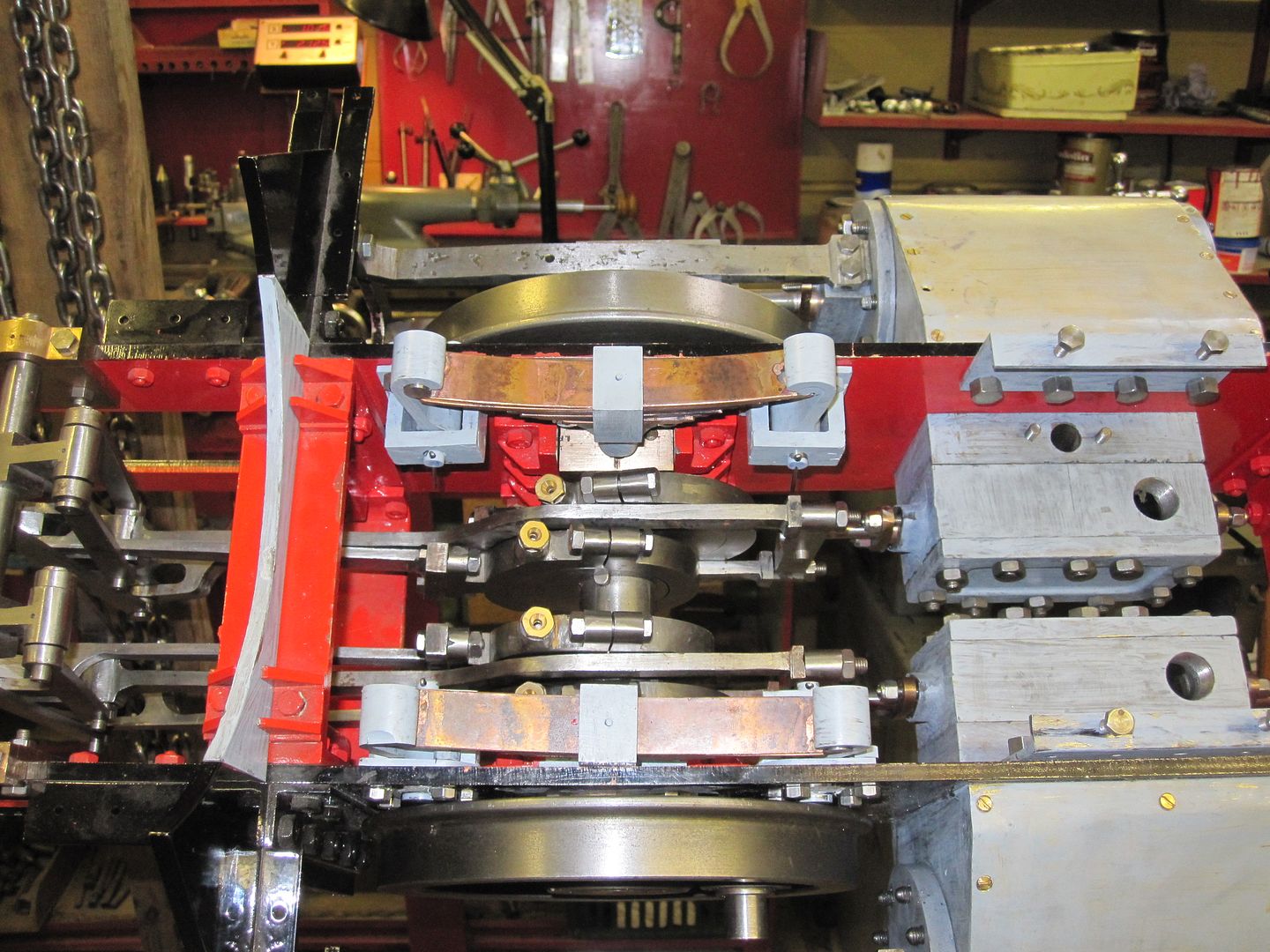

The completed Cylinders ready to be attsched to the frames, and the internal steam chests.

The following pictures show the steam chests and associated parts . The steam chests are very close together and adjustments very tricky. Not something to be tried once the boiler was in place. I consulted Ken Swan at this stage. It was a considerable relief when testing with air was completed without problem.

The stirrup nlike links were cut out of plate using a band-saw and finished by milling and much filing. these are this shaped to get round the front axle to the steam chests. I suspect that some of the early Fletcher Jenning locomotives may have had a sinle curved rod rather than the more symetrical stirrup.

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jul 5, 2022 20:46:03 GMT

The connectng rods were cut out of steel plate on a band saw. To compensate for internal stresses the cuts were made symetrically . The following pictures shows the effect of the internal stesses.

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jul 12, 2022 17:14:31 GMT

The connecting rods are some xxxxxxxxinches reflecting the unusually long wheel base. I find the thinking behind this design challenging. Puttinh thr firebox in front of the back axle distributes the weight evenly and allows a very deep firebox. The long wheel base prevents the waddling movement of short wheel base 0-4-0s

The front axle is about to becme a very busy space

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jul 16, 2022 16:48:37 GMT

The two images above shown the expansion linand lifting arms.The stirrups attached to the trunnions pass round the front axle to the steam chests.

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Jul 16, 2022 16:59:18 GMT

The expansion links seen from the side of the locomotive.

The lifting arms and weight shaft seen from above. |

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Aug 3, 2022 17:17:42 GMT

The engraved image at the beginning of this post clearly shows a handle at the bottom of the smoke box door which appears to be flat. Howver, the earliest photographs of Dolgoch show a circular convex door with a central dart clusure. The disadvantages of the top opening door, difficulties with a very weighty and potentially dangerous item must have stimulated development of the circular closure supprted by a side hinge.

Anyway Jim Reesliked the older version which I made slightly improved with an internal plate to protect against excessive heat.

The lock at the bottom of the door failed to close properly resulting in leakage and poor steaming and has been replaced by two extenal screwed levers which seal the door.

|

|

milky

Seasoned Member

Posts: 120

|

Post by milky on Aug 11, 2022 23:35:26 GMT

cracking pictures and project

|

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Aug 18, 2022 11:01:33 GMT

Hi Adrian,

A very interesting project - well done!

Do you have a copy of Boyd's book 'Talyllyn Railway'?

Cheers,

Julian

|

|

|

|

Post by ettingtonliam on Aug 20, 2022 12:11:33 GMT

The early LNWR 0 6 2 Coal Tanks had a slightly inclined front to the smokebox, with a flap type door like yours, but had a hook and chain fixed to the lamp bracket at the top of the smokebox to secure the door when in the open position. By about 1890 these were being replaced with a conventional dished vertical door with central handwheel and dart fixing, aided by a couple of clamps at the bottom.

Curiously, Martin Fuller's book 'Talyllynn & Corris Steam Locomotives - Appendices to Volumes 1 & 2' has 2 etchings taken fropm 'The Engineer' April 1869, one of which shows a 'conventional' dished smokebox door, so why they reverted a couple of years later to the flat lift up flap door for the Talyllyn locos, I don't know.

(I've got Vol 2 of Martin Fuller's book 'Talyllyn & Corris Steam Locomotives' but omitted to get Vol 1 when it was in print!)

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Sept 5, 2022 17:52:29 GMT

Thanks for kind comments. Yes I’ve got the book on the Tallinn Railway..

I was not aware of the Fuller books and engravings and would certainly like to see them. The locomotive is now steamed at the Tyneside Society of Model Engineerd is in Newcastle. The blower is less effective than I would like, The considerable depth of the firebox means that there is a considerable depth of coal, and compared with my WREN it is difficult to recover steam pressure from much less than 20lb

|

|

adrian6881

Active Member

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Following closure of Beamish Model Engineering group in 2020 I am now a member of TSMEE

Posts: 34

|

Post by adrian6881 on Sept 5, 2022 17:53:26 GMT

I was unable to transfer video from Photobucket, but succeded when I transfer images to YOUTUBE. I would welcome advice about Photobucket transfer. Ignore the suggestiohn to watch on youtube.

|

|

d certificated in 2020. Shown above is the test on compressed air. The air compressor was originally used by Beamish Museum in firing full size locomotives by injecting air into chimney. The chassis is being painted during construction.

d certificated in 2020. Shown above is the test on compressed air. The air compressor was originally used by Beamish Museum in firing full size locomotives by injecting air into chimney. The chassis is being painted during construction. d certificated in 2020. Shown above is the test on compressed air. The air compressor was originally used by Beamish Museum in firing full size locomotives by injecting air into chimney. The chassis is being painted during construction.

d certificated in 2020. Shown above is the test on compressed air. The air compressor was originally used by Beamish Museum in firing full size locomotives by injecting air into chimney. The chassis is being painted during construction.![]() It was my general intention to complete this locomotive in the form which it might have been delivered rather than the locomotive which has evolved over the century on the Tallylynn Railway. The illustration of the general type shown has a flat appearance of the smoke box door which suggests it may have opened upwards. From practical experience I can say that this not only restricts access but also is dangerous unless properly secured.

It was my general intention to complete this locomotive in the form which it might have been delivered rather than the locomotive which has evolved over the century on the Tallylynn Railway. The illustration of the general type shown has a flat appearance of the smoke box door which suggests it may have opened upwards. From practical experience I can say that this not only restricts access but also is dangerous unless properly secured. .jpg?width=450&height=278&fit=bounds&crop=fill) The other point to be noted is that there are helical springs for the front wheel ( and also at the back, though not visible). This was standard for Lowca but the narrow gauge of Dolgoch moves the springs to the midline. This would have placed them in the boiler and as a result leaf springs were substituted . Unfortunately I did not notice this and as a result have a spare set of helical springs. On offer to any builder of Dolgoch. Also visible is the unusually long wheelbase, with the firebox in front of the back axle. The originals supported the boiler by extensions of the motion bracket, the model has conventional wings on the firebox resting on the frames. Eccentrics for the Fletcher-Jenning motion are on the front axle.

The other point to be noted is that there are helical springs for the front wheel ( and also at the back, though not visible). This was standard for Lowca but the narrow gauge of Dolgoch moves the springs to the midline. This would have placed them in the boiler and as a result leaf springs were substituted . Unfortunately I did not notice this and as a result have a spare set of helical springs. On offer to any builder of Dolgoch. Also visible is the unusually long wheelbase, with the firebox in front of the back axle. The originals supported the boiler by extensions of the motion bracket, the model has conventional wings on the firebox resting on the frames. Eccentrics for the Fletcher-Jenning motion are on the front axle..JPG) Laser cut frames on building frame. All parts were primed and painted before erection since it was clear this would be impossible once the boiler was in place. The front axle had been made with eccentrics wrongly placed, as a result the wheels had to be removed and the eccentrics replaced correctly.

Laser cut frames on building frame. All parts were primed and painted before erection since it was clear this would be impossible once the boiler was in place. The front axle had been made with eccentrics wrongly placed, as a result the wheels had to be removed and the eccentrics replaced correctly. This image shows the first major blunder. The helical springs have been fitted on the front . The steel rule indicates the wall of the boiler. There was considerably more work in manufacturing the leaf springs.

This image shows the first major blunder. The helical springs have been fitted on the front . The steel rule indicates the wall of the boiler. There was considerably more work in manufacturing the leaf springs.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.JPG)

.jpg)

.JPG)

.JPG)