Post by John Baguley on Aug 4, 2021 16:04:54 GMT

I've spent the last two afternoons fitting the DRO kit to the ML7 and it was all pretty straightforward and everything fitted as it should. There is one thing that I'm not happy about but I'll mention that later.

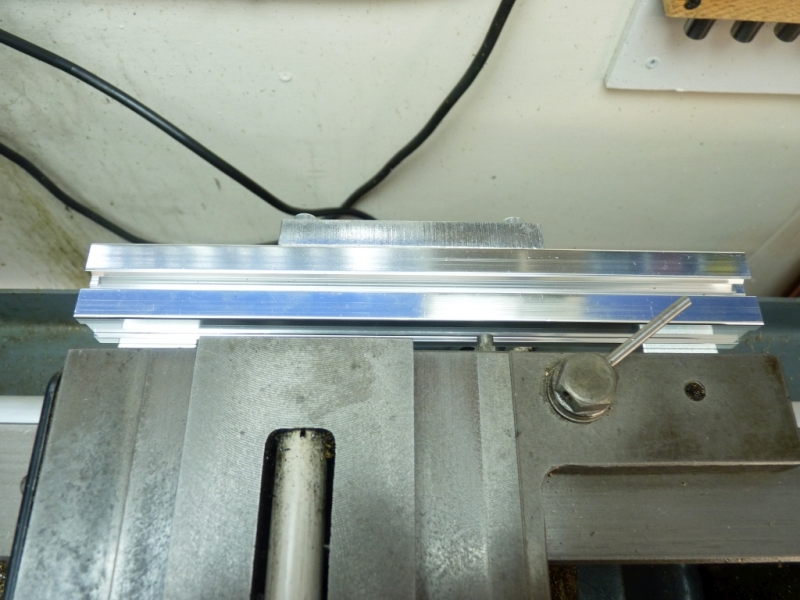

The first bit fitted was a length of aluminium extrusion which is mounted to the saddle using a couple of brackets bolted on using the existing bolt holes used to hold the rear saddle clamp.

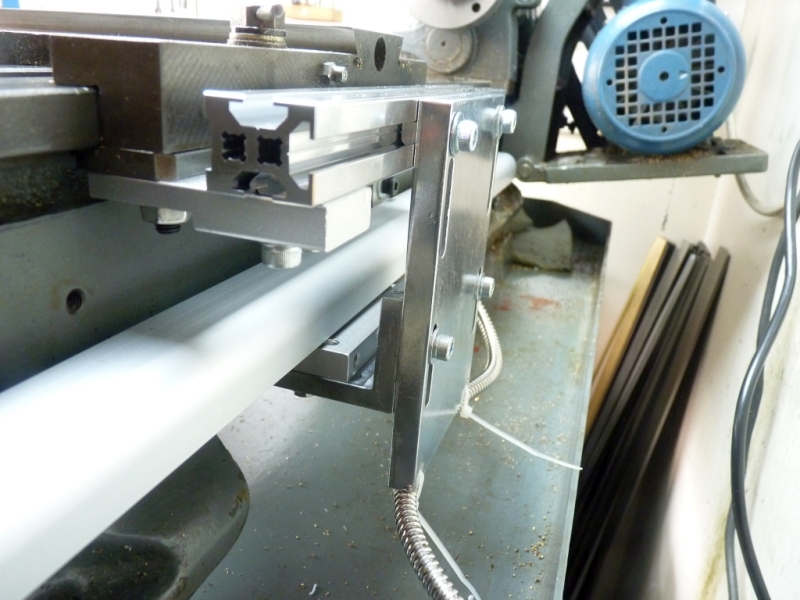

The Z axis scale mounting was the next to go on and that simply bolts to three of the existing threaded holes in the back of the bed using three brackets. I believe these tapped holes were meant to fit a taper turning attachment. Needless to say, you can't fit this kit if you do have the taper attachment fitted and want to keep it.

The mounting has a slot milled in it to take the magnetic strip which simply sticks in place with double sided tape. A thin stainless steel strip goes over this to protect it and an aluminium cover goes over the lot to keep swarf out.

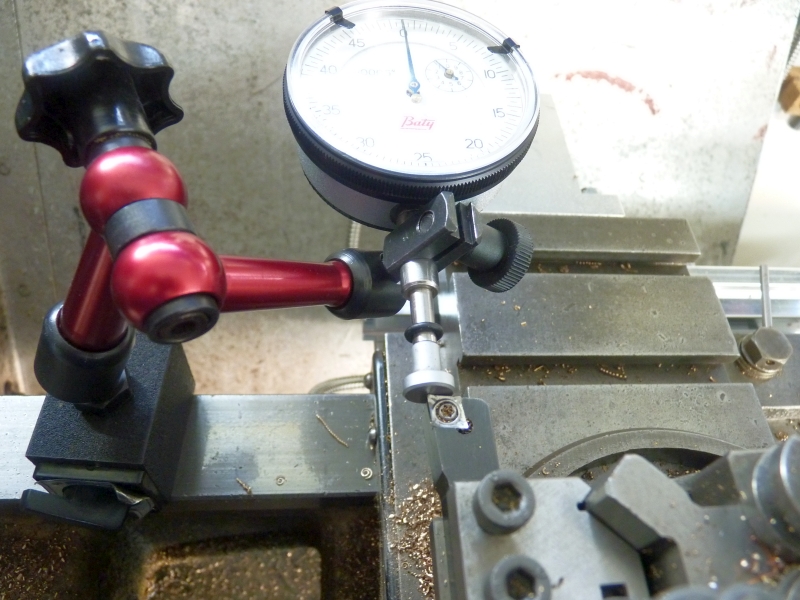

The read head is mounted to the previously fitted aluminium extrusion using a couple of brackets.

On to the X axis now and this is perhaps where the faint hearted should look away as it involves drilling and machining the cross slide casting!

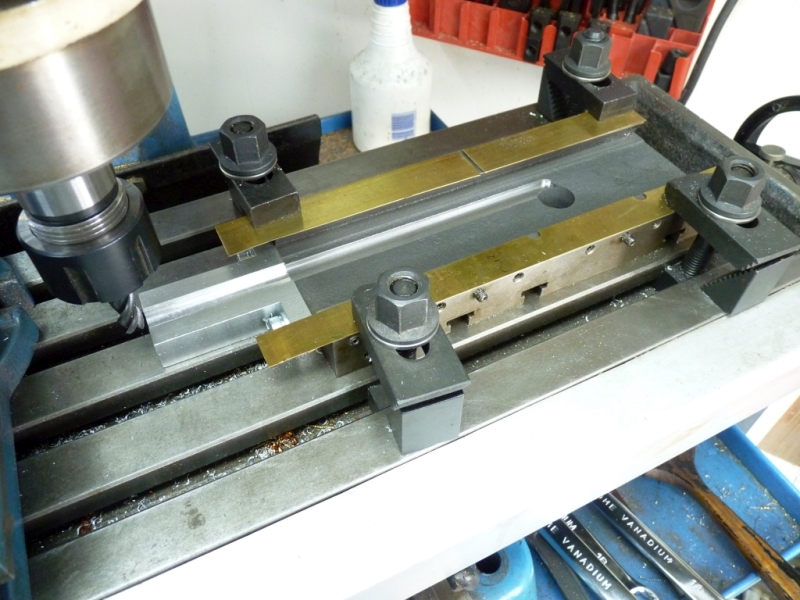

The first job is to drill and tap two holes in the end of the cross slide casting to bolt on an aluminium extension piece. This enables the magnetic scale to extend back behind the cross slide.

I only just had enough headroom on the mill to do this and the mill head was right at the top of it's travel.

The extension piece was then bolted on.

Next, a 10mm wide by 1.8mm deep slot has to be milled into the underside of the cross slide to take the nagnetic scale.

I found that the scale was actually 10.2mm wide so had to widen my initial slot slightly. Once again, the magnetic strip is stuck in place with double sided tape and a thin stainless cover stuck over that.

The slot for the scale doesn't actually need to be this long but I just made it the same length as the magnetic strip.

After refitting the cross slide to the lathe the next job was to fit the read head, again to the aluminium extrusion using one bracket.

Finally, the disply was mounted on the wall behind the lathe, all the cables connected up and it all worked first time

Fortunately, I didn't need to move any of the stuff that was already behind the lathe as I have a couple of racks etc. for my tooling that I didn't really want to move.

As usual, the cables for the scales were miles too long so the excess is just hanging down behind the lathe stand. I may shorten them but that would probably invalidate any warranty.

So, what don't I like about it? The cross slide scale does not read the full travel of the cross slide. As you wind the cross slide out, the scale loses contact with the read head after about 3 inches and consequently the DRO stops reading. On my lathe at least the cross slide has another 1.75" of travel before the feed screw disengages from the nut. I can see this being a problem when turning large diameters and the cross slide is towards the end of it's travel as I won't be able to use the DRO for measurement.

The magnetic scale is plenty long enough to read the total movement but it needs to be moved further back by about 2 inches so it remains in contact with the read head. in other words, the aluminium extension bolted to the back of the cross slide needs to be a lot longer. Whether this does become a problem remains to be seen. If it does then I will make a new longer extension piece and move the magnetic scale further back (if it will come unstuck again!)

Apart from that, I'm very happy with the kit.

John