|

|

Post by William A on Aug 13, 2021 10:59:13 GMT

Good morning all,

I'm sure like most here I've been following MrCrispin on YouTube and his build of the LNER B1. As a Rolls Royce jet engine machinist his techniques appear to my untrained eye to be near perfect. One of the things he did for his B1 was to fabricate the cylinders from steel, using cast iron sleeves for the cylinder bore.

I investigated this for the Maid of Kent, and seems like it would be fairly straight forward - a rectangle of cast iron with some minor shaping. For my second choice, a Don Young Hunslet, the cylinder casting is quite different with a very large mounting plate and reinforcing ribs which neccesitate the removal of large amounts of material and shaping some fairly interesting shapes:

I am fortunate in that I have a new-to-me Centec 2B with a horizontal overarm and a vert head - so I don't believe that there should be a major issue for either, but have I overlooked something obvious?

The main point for me is that fabricating from a chunk of cast iron means I can buy myself a new rotary table to help machine it and still have change left over, compared to buying the castings for either. The cost of buying steel, with a cast iron liner is about the same.

|

|

mbrown

Elder Statesman

Posts: 1,782

|

Post by mbrown on Aug 13, 2021 11:14:58 GMT

I did a thread on my "Fabricated Cylinders for 99 3462" on this forum a year or two ago. I used brass and bronze, and they were piston valve cylinders, but they came out fine.

The design, in this case, dictated fabrication rather than castings. Overall, I think it took longer than machining castings, but the individual pieces were smaller and things like the passageways were easier.

So, swings and roundabouts I think.

Malcolm

|

|

|

|

Post by William A on Aug 13, 2021 12:43:53 GMT

Ah, I've read through your thread now - fantastic stuff! I'd not considered subassemblies, I assumed that milling from solid would be the most straight forward approach. I believe that Mr.Crispin used a shrink-fit for his CI liners into the steel cylinders but it's not clear to me if there's an advantage to doing it like that vs. from solid CI.

|

|

millman

Part of the e-furniture

Posts: 323

|

Post by millman on Aug 13, 2021 18:14:21 GMT

On the plus side for fabricating or machining from solid is that you will not get hard spots or blow holes. Some of the castings available today are rubbish, unfortunately it doesn’t stop the suppliers charging an absolute fortune for them. I am at present machining a set of gunmetal Simplex cylinder castings for a friend and they are terrible, loads of machining allowance on one face and next to none on another face, hopefully they will just about come out ok. Boring the things is going to be interesting, loads to come off on one side and the other has barely a millimetre, a block of bronze would have been half the cost of the castings and would have been machined completely in a couple of days, the castings have taken three days and will take about another three days to complete, for me it’s a no brainier, fabricate or machine from solid every time.

|

|

|

|

Post by 92220 on Aug 13, 2021 18:43:19 GMT

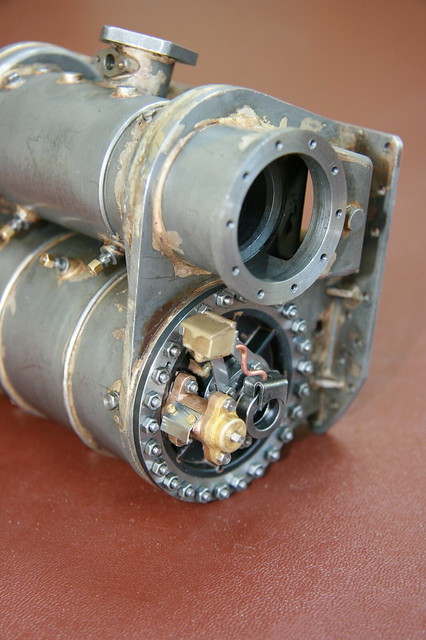

Building your cylinders is not a difficult job. It is just a bit time consuming if you want to make a scale version of a cylinder. A simple cylinder would not take anywhere near as long. I built up my cylinders, and scale versions of the fullsize cylinders, just scales down from the BR drawing. I just had to decide which parts to make up the finished cylinder. These are photos taken during the build:-  cylinder parts 001 cylinder parts 001 by Robert Shephard, on Flickr  cylinder parts 002 cylinder parts 002 by Robert Shephard, on Flickr  cylinder parts 003 cylinder parts 003 by Robert Shephard, on Flickr  cylinder parts 004 cylinder parts 004 by Robert Shephard, on Flickr  cylinder assembly 006 cylinder assembly 006 by Robert Shephard, on Flickr  cylinder assembly with rear steamchest cover 001 cylinder assembly with rear steamchest cover 001 by Robert Shephard, on Flickr  cylinder assembly with rear steamchest cover 002 cylinder assembly with rear steamchest cover 002 by Robert Shephard, on Flickr There has been a lot of discussion on the forum, about multiple silversolderings of a single assembly. My cylinders took around a dozen separate soldering sessions to finish and all done with the same spec silversolder. What probably isn't well known, is that when silversolder is melted for the first time, it's future melting temperature is quite a bit higher than initially, and each time it is heated and cooled (not necessarily melted) it's melting temp increases a bit each time. This means it is quite safe to do multiple heating silver soldering on the same assembly and not melt previous joints. I've done that many times over the years I've been making the loco, and have never had a previous joint melt. As long as you have a reasonable thickness cylinder liner and valve liner, that can be machined insitu, after all silversolder is done, any minor deformity, which will be only a matter of a few thou, will not matter as long as there is enough machining material to finish machine the assembly. I'd say, go for it. Bob. |

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,856

|

Post by uuu on Aug 13, 2021 19:00:30 GMT

I did Jessie's from castings. Next time I think I'd start with a brick of cast iron. It would probably take me longer, but I wouldn't be faced with the difficulties of crusty bits, or undersized areas. And be cheaper.

I use a replaceable tip milling and lathe cutters for cast iron, and it's a lovely material to machine.

Wilf

|

|

|

|

Post by ejparrott on Aug 13, 2021 21:19:41 GMT

I think you're confusing fabricating and machining from solid. Fabricated cylinders are normally steel parts welded, brazed or soldered together with iron inserts. You then say you have a block of iron big enough to make the cylinder, that is machining from solid.

Both are entirely doable, from solid is my preference. I never buy cylinder castings, the exception being the likes of Stuart Turner stationary engines where they come as part of the kit. Even the massive cylinders on my Manning Wardle are machined from solid

|

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Aug 17, 2021 0:31:01 GMT

You are missing the wedge shaped piece which goes from the top of the cylinder to the top of the flange that bolts onto the frame.

On my second Hunslet I am fitting extension blocks to the inner face to keep the valves in line as in the full size ones.

I made a pattern and anciently Norman Spink cast 4 of them. I have been doing them for years.

Reeves castings require bits added for the wedges as the cylinders also fit another locomotive.

I also like making Cylinders from solid lumps these days as the price rockets.

Mr Crispins TOOTHBRUSH is the interesting tool in his workshop!!!

Especially when he cleans it out in paraffin ready to return it to the Bathroom for his Brother to use.

David and Lily.

|

|

|

|

Post by terrier060 on Aug 19, 2021 19:42:01 GMT

I think fabrication is a wonderful idea and it has the great advantage that the cylinders can be really well insulated. I was going to fabricate my B1 cylinders, but I found so many major alterations from the full size made by Martin Evans, the worse being the wheel centres, that I gave up the project and decided to build the Terriers from works drawings. It was not so easy to fabricate the inside cylinders, so I made patterns and had them cast by Max Edwards, sadly now no longer with us. With hindsight I wish I had fabricated them. It is much easier to keep to scale, though I suppose using the lost wax or however Cro does his one can get some amazing results.

Ed

|

|

jasonb

Elder Statesman

Posts: 1,234

|

Post by jasonb on Aug 20, 2021 6:31:49 GMT

As a first project for your new mill I would suggest the cylinders are not a good place to learn how to use a mill. Get some practice in on less complex parts and then decide if you feel upto fabrication or cutting from solid. On the fabrication front have you silver soldered before?

Have a look through the build here where there are some very good ones being done without castings, make a note of the tooling being used as well as methods and then see what you need to obtain and learn to use for your own job, your reluctance to use a DRO will possibly change as you tackle this.

|

|

|

|

Post by howard51 on Aug 21, 2021 19:51:53 GMT

I machined my 3 1/2” Evening Star cylinders from steel and fitted Ph. Br cylinder liners no real trouble other than being a good test for the SX2P mill. Now started a 5” Super Simplex, was considering castings but am moved to use cast iron and machine from solid for both the wheels and cylinders. Just have to redesign the pumps to fabricate from bar.

|

|