darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Aug 17, 2021 11:40:05 GMT

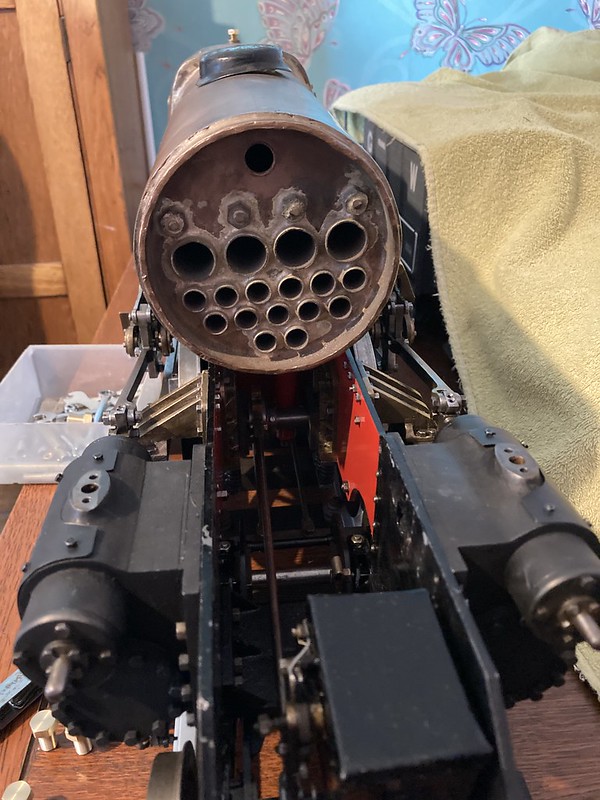

I'm sorry if these are daft questions. I'm (understandably I hope) apprehensive when it comes to the possibility of pointing drills near boilers, even if it's to tap the wrapper.

I have a nicely made boiler for my project Brittania which has passed a 180psi hydraulic test and I'm looking at the installation and fittings aspects.

As it stands, it has the following accesses

On the backhead

A pair of 1/4 x 40 bushes for the water sight glass 1off 1/4 x 40 bush at the bottom right. For a blowdown valve or a feed clack valve?

A tapped/no bush regulator hole A tapped/no bush 1/4 x 40 hole top right of the backhead, level with the regulator hole. I wonder if this was originally for the blower pipe, however there is no corresponding hole on the front plate of the boiler

On the top

A pair of 3/8 x 26 safety valve bushes undrilled steam dome ring A 5/6x32 manifold bush

On the front A tapped/no bush regulator hole.

The usual top/side mounted water feeds are not present Is it uncommon to fit bushes for these and the blower after an initial shell test? LBSC seems to indicate it's not going by the construction notes. I feel like I would probably want to avoid fitting bushes to it now that it's tested well unless it's unavoidable. It'll probably need to be though, to accomodate the axle pump and injector feeds.

Some pictures:

I was wondering how best to accomodate the fittings if I could work with it as it stands;

Live blower outside of the boiler, fed by the manifold Pressure gauge from the manifold Whistle from the manifold injector steam feed from the manifold

Axle, hand pump and injector feeds - possibly one can use the bottom right bush

blowdown valve probably needs to be in the usual position towards the front of the firebox, as it's the lowest point.

|

|

|

|

Post by Jim on Aug 17, 2021 12:57:11 GMT

The boiler looks as if it could be a variation of J Perrier's design who drew the first set of 5"g Britannia drawings for which Wilwau made the castings. If that's so I think the the bush on the lower right hand side of the back head is actually for the boiler feed clack. Perrier actually had a matching one on the other side from memory.

If it would be of any help I could take a photo of Perrier's boiler backhead and post it here which might help sort out what the builder had in mind.

Cheers

Jim

|

|

darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Aug 17, 2021 14:20:26 GMT

Thanks very much Jim, if you could, that might be very helpful indeed. I had wondered if the lower right bush could be used for a feed clack but given my only experience of them so far has been the top-mounted types, I wasn't sure if there was a reason that it couldn't be used which I just didn't understand.

The boiler maker himself (ex-railwayman Syd Rowland of the Urmston society) has made quite a few Brit boilers in his time, including his own 5" Brit pulling 22 passengers pictured in ME. I expect he may have evolved this from a scaled-down design that worked well and then opted to keep it low maintenance in terms of a live blower, or perhaps intended to go the original LBSC flanged fittings for the feeds on installation?

Cheers

Darren

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,857

|

Post by uuu on Aug 17, 2021 15:17:55 GMT

Plenty of boilers have feed clacks low down on the backhead. It's not ideal, but if it's what you've got then you might as well use it. But having all you feeds sharing it might mean having a little manifold below the footplate.

You don't mention a bush for a blowdown, although you do note that front of firebox would be the usual place. If you not got one, then that's a shame - you might find yourself removing the feed clack to wash things out.

The threaded hole to the right of the regulator might be a small challenge. If you're not going to use it, might there be some chance of coaxing a blanking plug from the inside out (almost impossible, I know)? With a nut on the outside.

Drilling the ring of fixing holes in the dome bush might be best tackled in a milling machine with fine down feed. Easier to prevent you plunging beyond your desired depth.

As with all things boiler related, discuss with your club inspector.

Wilf

|

|

darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Aug 17, 2021 17:52:48 GMT

Thankyou Wilf  It's good to hear the lower type of clacks are not totally uncommon. There's no blowdown bush sadly - I really don't want to be removing fittings to wash it out. I'll give that some consideration. Regarding to the threaded hole to the right of the regulator - using it for the pressure gauge or whistle take-off would be ideal. I had a feeling all fittings should be bushed these days but haven't read up to confirm that. If I can get away with that, it'd be ideal. If not, I think i could probably get a blanking plug inserted from the inside and place a nut on the outside - that's a great suggestion. As you say though, all best discussed with the club inspector to decide on an approach. |

|

|

|

Post by Cro on Aug 17, 2021 18:19:42 GMT

Considering you appear to be missing some bushes I would advise, with the support of your club and boiler inspector, to add the missing bushes from someone with experience of doing so.

The two top feeds are fairly easy, putting a bush in the throat plate for a blow down is a bit more risky (I’m considering the same on my 5” 9f boiler) and whilst it’s hot I’d get ones in on backhead and tube plate if you can. In truth a Brit has its regulator down the side of the boiler and in the Smokebox so you could bush the backhead and then just bung it up and forget it but it’s up to you how authentic you want it to be.

Fittings wise a simple manifold in the style of the BR ones can be made and supply everything you need (this is how grandad did his) with blower on the outside etc.

Adam

|

|

|

|

Post by Jim on Aug 18, 2021 5:08:46 GMT

Thanks very much Jim, if you could, that might be very helpful indeed. I had wondered if the lower right bush could be used for a feed clack but given my only experience of them so far has been the top-mounted types, I wasn't sure if there was a reason that it couldn't be used which I just didn't understand. The boiler maker himself (ex-railwayman Syd Rowland of the Urmston society) has made quite a few Brit boilers in his time, including his own 5" Brit pulling 22 passengers pictured in ME. I expect he may have evolved this from a scaled-down design that worked well and then opted to keep it low maintenance in terms of a live blower, or perhaps intended to go the original LBSC flanged fittings for the feeds on installation? Cheers Darren Hi Darren, These are JP's drawings of the boiler back head showing the bushes for the gauge glasses, two boiler feed clacks (lower left and right on the back head) and the the hollow stay feeding steam to the blower. The other drawings I've added to give a bit more detail, they include the details of the hollow stay steam line to the blower that runs down through the boiler to the smoke box. I used this system on 70036 Boadicea. Hope these are helpful. Jim The backhead.

Looking forward at the throat plate with the backhead removed A similar view looking forward at the tube plate. Details of the 'hollow stay' that feeds steam to the blower.

Sadly Perrier wasn't a draftsman so his drawings don't always follow the accepted layout which can lead to a 'Where's Wally' game as you search drawings for a missing detail such as the steam collection pipe he favoured. It looks like a flute and is on a nother sheet fitted in where JP found a space.

If I can be of any further help please send me a PM and I'll see what I what I can do. I should add I designed Boadicea's boiler to the AMBSC code.

Jim

|

|

darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Aug 18, 2021 20:32:45 GMT

Thanks very much Jim, that's hugely useful and much appreciated.

Darren

|

|

darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Aug 18, 2021 20:48:38 GMT

Considering you appear to be missing some bushes I would advise, with the support of your club and boiler inspector, to add the missing bushes from someone with experience of doing so. The two top feeds are fairly easy, putting a bush in the throat plate for a blow down is a bit more risky (I’m considering the same on my 5” 9f boiler) and whilst it’s hot I’d get ones in on backhead and tube plate if you can. In truth a Brit has its regulator down the side of the boiler and in the Smokebox so you could bush the backhead and then just bung it up and forget it but it’s up to you how authentic you want it to be. Fittings wise a simple manifold in the style of the BR ones can be made and supply everything you need (this is how grandad did his) with blower on the outside etc. Adam Thanks very much for the input Adam, it's really helpful. The outgoing boiler had the more authentic looking smokebox regulator and I have to say it seems a slightly easier proposition given everything is outside of the boiler. My other Brit has the slide-regulator inside the boiler. My only hesitation in adopting the smokebox regulator route with the working external linkage was that as I understand it, I'd need;

1) to bung up the large tapped regulator hole in the backplate 2) to braze a boss for the linkage mounting point on the left of the boiler 3) tap the backhead for the handle mount

Does that sound about right? Darren

|

|

|

|

Post by dhamblin on Aug 18, 2021 21:14:50 GMT

Could the regulator rod boss be attached to the boiler cladding only? Similarly the regulator handle mounted on firebox backhead cladding? This could simplify the modifications you want to make whilst making it look authentic.

Regards,

Dan

|

|

|

|

Post by Jim on Aug 19, 2021 5:28:40 GMT

Could the regulator rod boss be attached to the boiler cladding only? Similarly the regulator handle mounted on firebox blackhead cladding? This could simplify the modifications you want to make whilst making it look authentic. Regards, Dan That's exactley what I did Dan. I added a backing plate to the inner side of the cleading to give added rigidity to what is pretty thin sheeting and it works well. This is the regulator handle fitted to the backhead cleading. Here you can see the boss for the crank that operates the regulator actuating rods.

Cheers

Jim

|

|

darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Aug 19, 2021 9:33:54 GMT

Ooo. Thanks Dan and Jim. That sounds like it'd make things quite a bit easier. In that case I may opt to take that route. Easy when you know how, eh!  I can even re-use the original rods, crank and possibly the regulator taking this approach. I'd been thinking of cleading the backhead for the firehole doors, to avoid tapping the boiler and to keep things clean. So my only real concern would then be the best way to seal off the large hole on the backhead - presumably blanking plug sealed into the hole from the inside, nutted on the exterior? Probably one to ask my boiler inspector. I can't see a way to easily disguise the end result based on a prototypical backhead, although if I'm cunning, perhaps try and have the cleading cover it... |

|

|

|

Post by dhamblin on Aug 19, 2021 19:38:05 GMT

Silver solder the correct size boss in place for the dome regulator and cover it with the cladding/cleading. As for the firehole door - on Grandad's Brit he used a flange that slots into the firehole and has the door backing plate, doors and runners attached to it. Can be pulled out for easier maintenance.

Regards,

Dan

|

|

|

|

Post by Cro on Aug 20, 2021 7:04:09 GMT

If you are considering fitting the missing bushes correctly with S.Solder then I would look at doing all you can whilst at it for example the brackets for the regulator - I wouldn't rely too much on the cladding on a 3 1/2" it won't be thick or that rigid.

Adam

|

|

darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Aug 21, 2021 12:04:42 GMT

Silver solder the correct size boss in place for the dome regulator and cover it with the cladding/cleading. As for the firehole door - on Grandad's Brit he used a flange that slots into the firehole and has the door backing plate, doors and runners attached to it. Can be pulled out for easier maintenance. Regards, Dan Genius. I'm adopting this. Thanks for the tip Dan

As you're mid-restoration is there any possibility of some photos of the aforementioned flanged door assembly? I checked the thread but only ever see it fitted or absent!

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,988

|

Post by JonL on Aug 21, 2021 22:12:19 GMT

Silver solder the correct size boss in place for the dome regulator and cover it with the cladding/cleading. As for the firehole door - on Grandad's Brit he used a flange that slots into the firehole and has the door backing plate, doors and runners attached to it. Can be pulled out for easier maintenance. Regards, Dan Genius. I'm adopting this. Thanks for the tip Dan  Me too! |

|

|

|

Post by dhamblin on Aug 22, 2021 19:15:06 GMT

Hope to get a burst in the workshop next weekend - will get one then.

Regards,

Dan

|

|

|

|

Post by dhamblin on Aug 30, 2021 20:25:09 GMT

Photo as promised:  Britannia Firehole Doors Britannia Firehole Doors by Daniel Hamblin, on Flickr The piece that inserts into the firehole is sized to be a tight fit and the cut out obviously allows a degree of flex to allow it to be pulled out with sufficient force. Regards, Dan |

|

darrene

Part of the e-furniture

Posts: 440

|

Post by darrene on Sept 1, 2021 17:45:51 GMT

That's brilliant. Thanks very much Dan. A nice piece of work too.

|

|