|

|

Post by runner42 on Aug 23, 2021 0:08:58 GMT

I want to produce a boiler connection for the pressure gauge that is independent from the manifold. I have seen what I want to produce but do not know what name it goes by so I can't Google to find out how it is constructed internally. I have a small photo of what it looks like. Any name and or construction diagram would be much appreciated. Brian  pressure gauge pressure gauge by Brian Leach, on Flickr |

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,858

|

Post by uuu on Aug 23, 2021 6:37:11 GMT

Are you referring to the hex-headed bit just to the right of the gauge? That looks like a "Banjo" fitting.  Wilf |

|

|

|

Post by runner42 on Aug 23, 2021 7:25:58 GMT

Thanks Wilf, that's it. How is the pressure contained, is it just the closeness of the ring to the shoulder, or due to the washers? I thought that O ring sealing would feature in the design?

Brian

|

|

|

|

Post by Jo on Aug 23, 2021 7:30:44 GMT

Below the pressure gauge you can see a U shaped tube which connects to the manifold: This is known as a Syphon tube.

Pressure gauge syphons are used to protect the pressure gauge from the heat effect of the steam and also to reduce the effect of rapid pressure surges. As the steam goes down the tube it is collected inside the bottom of the U or coil portion of the syphon so (hopefully) does not get inside the pressure gauge.

They are a simple U shaped copper tube with fittings on either end to suit the pressure gauge and in your photo a loop fixed with a banjo bolt to the manifold. In Wilf's picture the two banjo washers are made of aluminium. When you tighten up the bolt they are crushed against the manifold and the bolt head forming a gas tight seal.

Jo

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,858

|

Post by uuu on Aug 23, 2021 7:41:17 GMT

Thanks Wilf, that's it. How is the pressure contained, is it just the closeness of the ring to the shoulder, or due to the washers? I thought that O ring sealing would feature in the design? Brian If you Google images of banjo fittings, you'll see there are designs that use o-rings. They're often used in automotive brake fittings and fuel hoses, so they mustn't leak. In the one pictured, it's just the washers that do the sealing. So you need good flat faces on all the parts. Fibre washers, or soft copper ones can be used (or aluminium as noted by Jo). I must admit, I've never really liked them - probably because I've been trying to re-seal an old joint with old washers - you really need new ones each time! Wilf |

|

|

|

Post by ettingtonliam on Aug 23, 2021 11:40:20 GMT

Copper washers are best annealed.

|

|

|

|

Post by Deleted on Sept 7, 2021 13:32:31 GMT

Brian

[/quote]If you Google images of banjo fittings, you'll see there are designs that use o-rings. They're often used in automotive brake fittings and fuel hoses, so they mustn't leak. In the one pictured, it's just the washers that do the sealing. So you need good flat faces on all the parts. Fibre washers, or soft copper ones can be used (or aluminium as noted by Jo).

I must admit, I've never really liked them - probably because I've been trying to re-seal an old joint with old washers - you really need new ones each time!

Wilf

[/quote]

They are also used for turbo boost lines on cars, washers are copper or alloy and are usually best to renew when servicing is undertaken.

Pete

|

|

jackrae

Elder Statesman

Posts: 1,335

|

Post by jackrae on Sept 7, 2021 15:44:29 GMT

A 'simple' elastic o-ring should never be used with a banjo fitting as it'll tend to creep out as the fitting is tightened. As others have indicated a soft metal ring washer is required. You can get hydraulic washers (often referred to as Dowty washers) which comprise an outer ring of metal (usually plated steel or stainless steel) which has an elastomer bonded to the inner surface of the ring. When tightened, the elastomer forms the seal and is prevented from extruding by the metal outer ring (the ring not being the seal) If you google Dowty washers you'll see examples One benefit over plain soft metal washers is that they will seal with minimal torque being applied.

|

|

jasonb

Elder Statesman

Posts: 1,239

|

Post by jasonb on Sept 7, 2021 17:43:27 GMT

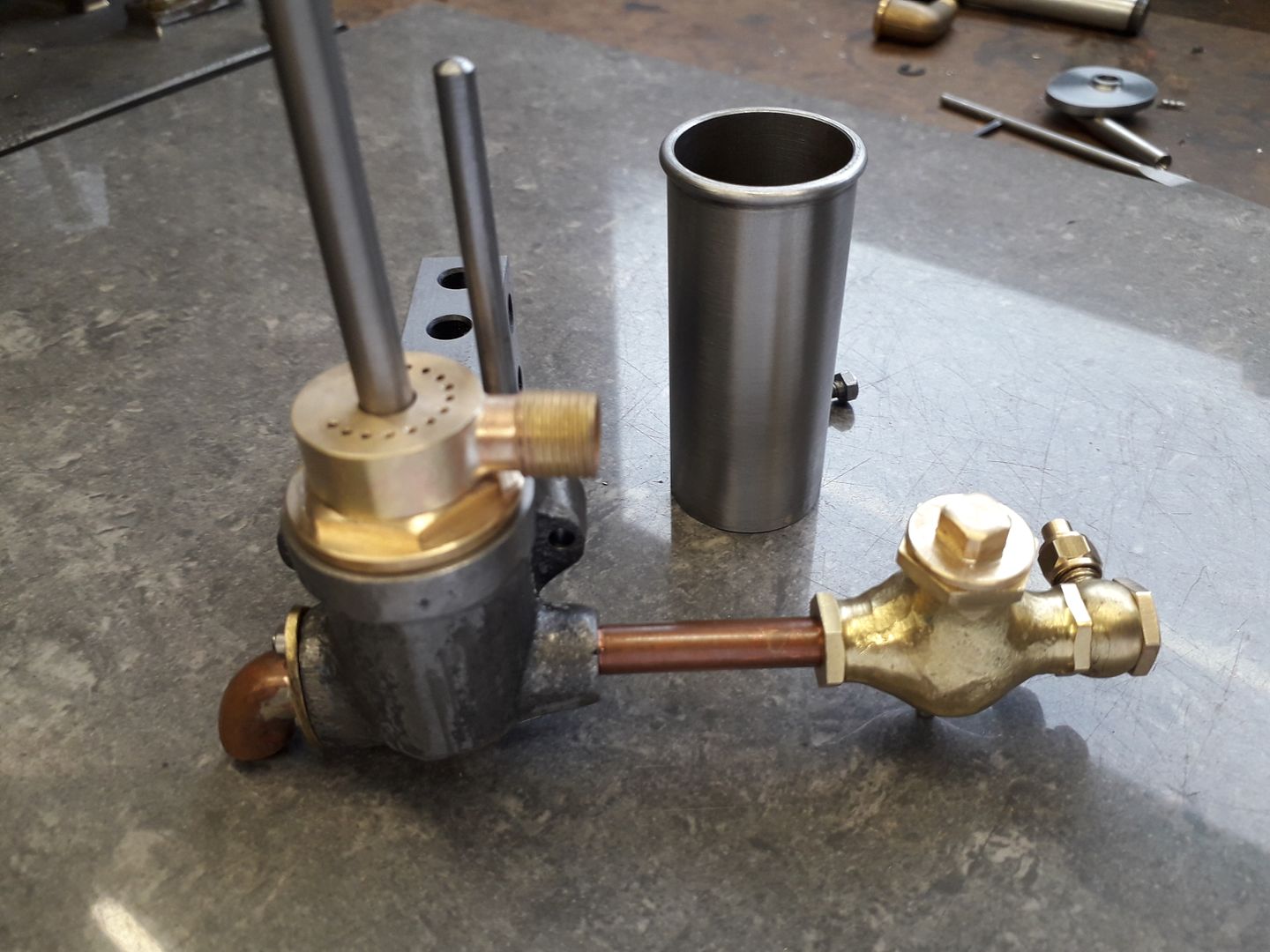

Soft copper washers should do, same as used to seal other steam fittings and get them in the right position banjo fittings are quite easy to make with a form tool or ball turner to mak ethe body then just a counterbore on teh side and silver solder in a threaded stub to take your nut and nipple. I nade this one for propane but same will work with steam   |

|