triton

Involved Member

Building a Southern Railway 5" Schools Loco

Building a Southern Railway 5" Schools Loco

Posts: 53

|

Post by triton on Jan 9, 2022 18:55:02 GMT

Can anyone give me some advice on the best way of making loco nameplates for a 5" gauge Southern Railway, School's class Stowe? I have read numerous articles whether to cast a brass nameplate, CNC machine a plate, laser engraving or etching. What is everyone's experience with either method and how successful are they in creating clean small lettering on the plates. Cost is also a factor, so should I get them made by a supplier instead of making them myself. Help would be appreciated!

|

|

|

|

Post by 92220 on Jan 10, 2022 19:47:16 GMT

Check with Diane Carnery to see if she already produces a nameplate for 'Stowe'. If she does, that's the way I would go. Failing that, she will always produce a one off name plate.This is her email address:- loco.nameplates@uwclub.net

Bob.

|

|

|

|

Post by Cro on Jan 11, 2022 9:17:33 GMT

Diane does the best acid etch plates.

I have done cast Schools plates "Ardingly" in 5" with cab side plates and also did Tonbridge and Brighton in 2 1/2" for Dads locos all from works drawings so if you wanted cast I can help there.

I would advise against CNC or Laser etching. Laser I've seen leaves a lot of marks on the surface and for CNC unless you have it on a long run time with tiny step over to remove all the marks of also doesn't clean up great - I had quotes for professional CNC once and it was crazy money.

Happy to help if you need it,

Adam

|

|

jasonb

Elder Statesman

Posts: 1,236

|

Post by jasonb on Jan 11, 2022 12:00:01 GMT

To me as a non loco man all the nameplate seem to have the background painted so should not be too hard to flow in a bit of high build primer filler and then the gloss which would hide any tool marks if a large stepover had been used. Though doing the majority of the background with a larger cutter will avoid too many marks saving the finer one for just getting into the tight spots. Though if you don't want to pay for the long machine time then why not just get separate letters CNC cut and solder them to the backplate which would easily be something you could do on a manual mill, once painted any soft solder won't show. As there are not many letters in STOWE then easy enough to line up What sort of font height are we talking about? Although these ones were painted all over it would have only needed a quick rub with emery to get the bare brass tops to show again, font is 8mm high  Don't suppose you will be going for the aged look either but should make no difference. These are also 1:1 scale so a bit more "cast" texture was desirable  |

|

triton

Involved Member

Building a Southern Railway 5" Schools Loco

Building a Southern Railway 5" Schools Loco

Posts: 53

|

Post by triton on Jan 11, 2022 20:49:10 GMT

Most of the people I have contacted will not produce a nameplate in the size needed (About 2-1/2" long) and the size of the letters. The people who did quote a price, I thought were way expensive. (Didn't want to buy a machine shop, just a nameplate!!) So I think the way to go is with Diane Carnery. Many thanks to the replies and thankyou very much for the help.

|

|

triton

Involved Member

Building a Southern Railway 5" Schools Loco

Building a Southern Railway 5" Schools Loco

Posts: 53

|

Post by triton on Jan 11, 2022 21:11:46 GMT

Thanks jasonb - The letters on my nameplate are less than a 7mm high and only about 0.5mm thick, so would be quite fiddly to make individually, so casting or etching I think is the way to go. Thanks for the reply and really nice work on your photos.

|

|

|

|

Post by 92220 on Jan 14, 2022 9:15:15 GMT

Diane Carney can definitely produce Black backgrounds on nameplates, but I'm not sure about other colours. Bob. Edit:- As far as 'Stowe' goes, if she produces the nameplate as a standard item, she will almost certainly also produce any other plates required, like cabside plates, that would make up the set. There is also someone on the 'net, advertising nameplates for 'Stowe', as an etched badge which looks good quality from the photo. They could almost certainly produce it as a 5" gauge nameplate as it is photo etched. This is their email hello@revgomm.co.uk This is their webpage that shows the 'Stowe' nameplate revgomm.co.uk/stowe--locomotive-etched-nameplate-973-p.aspBob. |

|

triton

Involved Member

Building a Southern Railway 5" Schools Loco

Building a Southern Railway 5" Schools Loco

Posts: 53

|

Post by triton on Jan 16, 2022 18:38:03 GMT

Thank you for the help 92220. I contacted Diane Carney and she is quoting plates for my Stowe. Meantime I will try your other suggestion as well.

I will keep post updated as soon as I decide which way to go.

|

|

triton

Involved Member

Building a Southern Railway 5" Schools Loco

Building a Southern Railway 5" Schools Loco

Posts: 53

|

Post by triton on Mar 21, 2022 20:42:45 GMT

I ordered my nameplates from Diane Carney. The quality is exceptional and much better than I expected.

Would certainly recommend her for nameplates.

|

|

abby

Statesman

Posts: 927

|

Post by abby on Apr 6, 2022 21:45:47 GMT

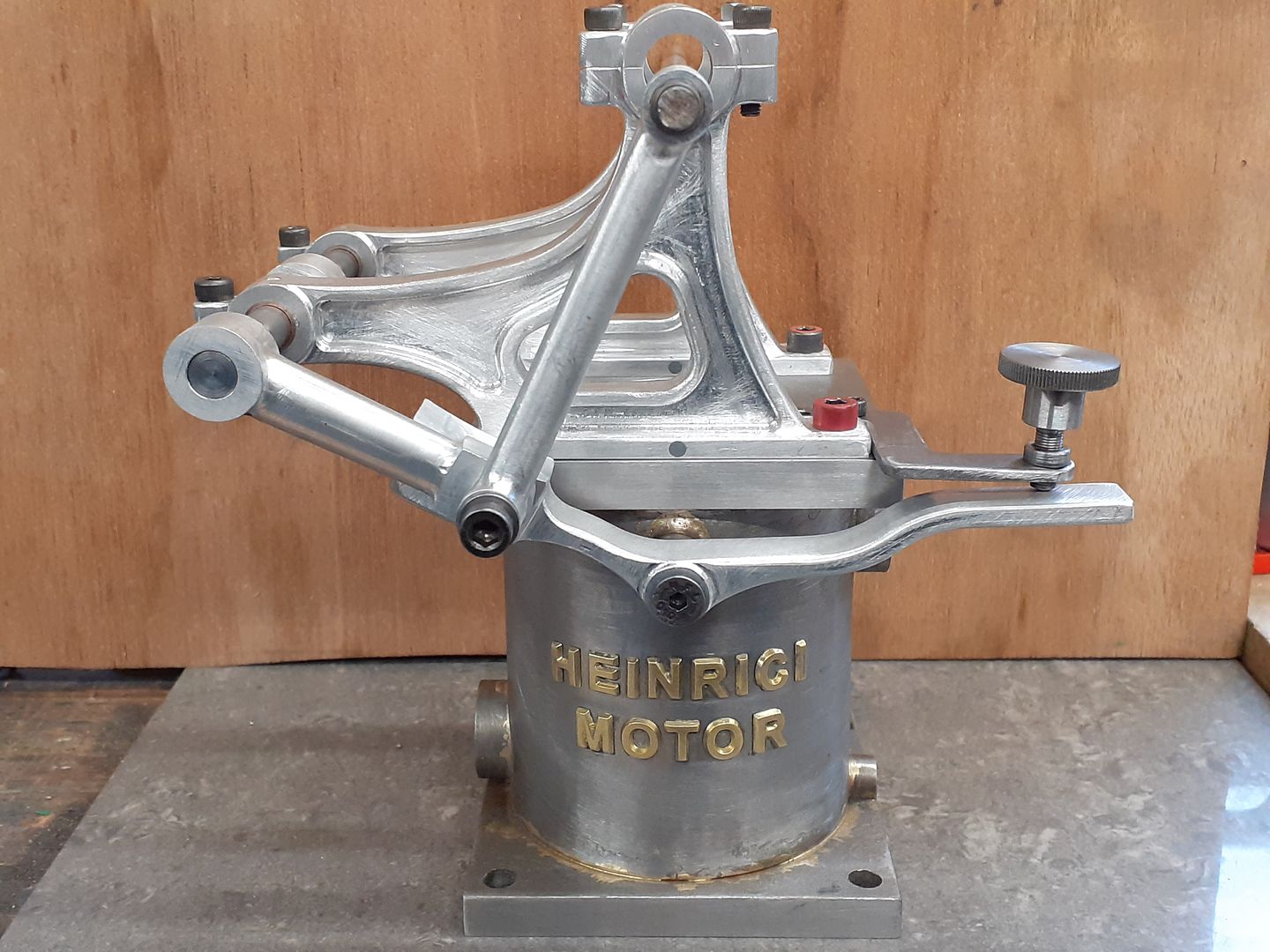

Photo etching at home can produce very acceptable results but has restrictions, the depth of cut is limited, usually to around 25 thou, beyond this depth the edges of the lettering are attacked altering the shape. Great care has to be taken to avoid any dust as even tiny traces can cause faults in the protective mask. Another problem arises if your name plates have shaped edges such as Merchant Navy Class then there is a lot of fine sawing and filing to get the outline. For my own requirements I prefer to design the part in 3D cad and then have the pattern printed. I use Shapeways.com for my prints as I find them to be cheap and reliable,and the prints require very little work to make them useable. I have had prints done in wax by another printer but have found that items such as gauge 1 engine nameplates are so delicate they often get broken in the mail. I take silicone moulds from the printed patterns and use these to produce wax copies which I then cast. Here is a steam chest cover as an example.   Dan. |

|

triton

Involved Member

Building a Southern Railway 5" Schools Loco

Building a Southern Railway 5" Schools Loco

Posts: 53

|

Post by triton on Apr 11, 2022 17:03:46 GMT

Nicely done. Thanks for the photos.

|

|

|

|

Post by victor358 on May 4, 2022 11:35:31 GMT

Good work!

|

|