44767

Statesman

Posts: 538

|

Post by 44767 on Feb 9, 2022 5:21:33 GMT

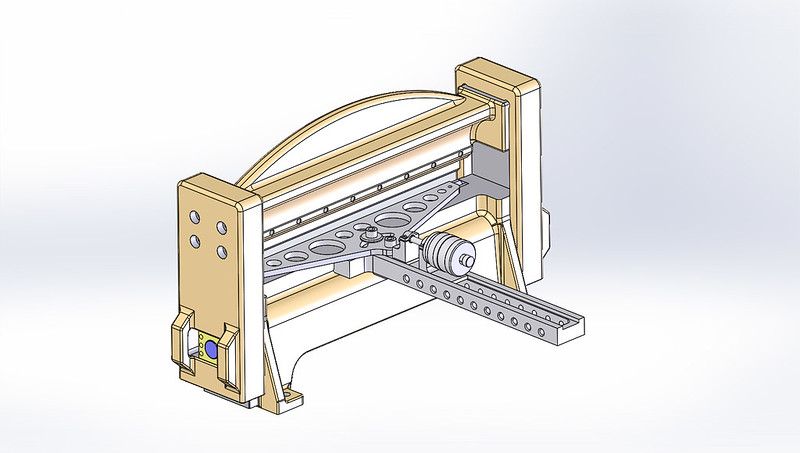

As a start, I'll post these two pictures of a press brake I built myself to do a lot of accurate folds on parts for my BR Standard Class 3 project. Sorry about the messy work bench!   It is based on one where I used to work but a little narrower so that I could machine everything at home. It has limit stops which can be set with slip gauges and also a micrometer-adjustable rear fence. With these refinements, folds can be repeated at a later date, having noted the settings and tooling used when the job was first set up. I'll post more photos of the machining processes later. Cheers, Mike |

|

|

|

Post by 92220 on Feb 9, 2022 8:59:28 GMT

Wow!! Lovely piece of work there Mike!!!

Bob.

|

|

|

|

Post by coniston on Feb 10, 2022 22:25:31 GMT

Unbelievable Mike, so professional looking and I bet much more accurate and precise than anything that can be bought.

Chris

|

|

|

|

Post by jamesrumble on Feb 11, 2022 6:56:52 GMT

That is a lovely looking piece of machinery, well done Sir.

|

|

|

|

Post by racinjason on Feb 11, 2022 23:32:09 GMT

Well done Mike,

do you have any drawings you would be willing to share with members.

cheers Jason.

|

|

44767

Statesman

Posts: 538

|

Post by 44767 on Mar 11, 2022 22:10:55 GMT

Well done Mike, do you have any drawings you would be willing to share with members. cheers Jason. Hi Jason, rather than spending time producing drawings, I could distribute the completed SolidWorks model as an edrawing. You don't need any software to view; it comes with the edrawing when you first open it. You can then see, measure, cross-section, hide etc. anything so you can make parts. The only thing is, the drawings are not useable for CAD/CAM work. I think they can be saved with an option to allow stl's to be saved from the parts, if you'd like to "machine your own castings". Here's an image of the SW assembly (not edrawing).  Cheers,Mike |

|

|

|

Post by KennLindeman on Mar 24, 2022 6:49:37 GMT

Hi Mike

Been taking a good look at the design and its is actual quite a simple design.The top and bottom frames do present a issue to make paterrns and to have them cast. I estimate that they are about 25kg each, so i think the total machine weight is about 100kgs. So Mike did you every weight it. I was also thinking that maybe it could be modified to be a guilletine or box pan folder.

Anyway Mike well done

|

|

44767

Statesman

Posts: 538

|

Post by 44767 on Mar 24, 2022 12:56:19 GMT

Ken,

You're spot on with the main casting! As cast, since it was not cored out. it weighed 40kg and after machining out the core and machining the casting itself, it came in at 25kg. I'm not sure about the strong back, but since you were correct on the other, it's probably about the same (although it doesn't seem to be as heavy).

|

|