dalboy

E-xcellent poster

Posts: 235

|

Post by dalboy on Oct 7, 2022 18:52:24 GMT

Hope this is the right place to ask this.

A question about collet storage. How do yu store yours a brought unit or a home made job or are you the type that just throws them in a draw  |

|

SteveW

Elder Statesman

Posts: 1,456

|

Post by SteveW on Oct 7, 2022 22:42:57 GMT

Bought a set of ER32 collect years back complete with an R8 driver. All came in one of those blown plastic cases. I've since bought an ER32 adaptor for my Myford nose.

Yes I solved the storage problem the easy way but still have to store the case. ER collects are easy, nice and short.

Having a heap of odd tools I finally pushed the boat and bought a big tool chests with drawers on wheels from Machine Mart then bought a little one to go on top. True not cheap but its solved a whole load of issues when it comes to finding tools, just open a drawer. The thing has been worth it.

As for storing your collects and assuming you bought them individually so no case best use your secondary school woodwork skills an knock something simple up to store and present them for easy choice. Best also plan of having room for the full set looking to the future. If you just go for some proprietary plastic case not design specifically for the collects you'll wish you made a box to hold them.

Maybe buy a plastic box then make an insert to manage and present your collects.

The only other alternative I can think of is a poly bag, a couple of squirts of oil and chuck your collects in that. Then chuck the poly bag somewhere where you'll find it again.

And don't forget the collect holder and draw bar.

|

|

|

|

Post by steamer5 on Oct 8, 2022 1:22:48 GMT

Hi Dalboy,

I used some ACM sign board, this is aluminum clad both sides of a plastic core mines 4 mm. Cut enough to go full width of the drawer … 360mm x 300 mm….after setting out the ER32 collets on one side & ER 25 on the other, drilled the holes with speedy bore wood drill bits, had space between for the square & hexagon collet blocks as well, the draw in only 70 mm deep. Allowed a couple of extra holes just because, & glued upstands on either side. Trouble is recently I needed a collet to hold 22mm, the sets etc only go to 20mm. Alipress to the rescue! I now have collets to 26 mm……..& need to remake it!

Cheers Kerrin

|

|

dalboy

E-xcellent poster

Posts: 235

|

Post by dalboy on Oct 8, 2022 7:38:19 GMT

Looks like I will design my own and make one from wood. I have been known to dabble with wood  . |

|

jem

Elder Statesman

Posts: 1,075

|

Post by jem on Oct 8, 2022 14:21:13 GMT

I use plastic pipe of the right size for all this type of stuff, can be got from a plumber, and cut it into suitable lengths, then make a simple wooden box to fit the pipes into. often a biscuit tin will house the pipes.

Jem

|

|

SteveW

Elder Statesman

Posts: 1,456

|

Post by SteveW on Oct 8, 2022 17:49:09 GMT

Looks like I will design my own and make one from wood. I have been known to dabble with wood  . Guess that'll be tree wood. Be warned the stuff is now quite expensive. It doesn't grow on trees. |

|

|

|

Post by cplmickey on Oct 9, 2022 13:20:06 GMT

I just put up a small shelf on the wall near my mill with the collets and tools for the mill on there. Everything is handy for that machine then. Made it from an old drawer that was being thrown out. The ER40 collets I buy come in a little plastic "tub" so easy to store on a shelf with no other fixings required. Ian

|

|

jasonb

Elder Statesman

Posts: 1,237

Member is Online

|

Post by jasonb on Oct 10, 2022 6:05:46 GMT

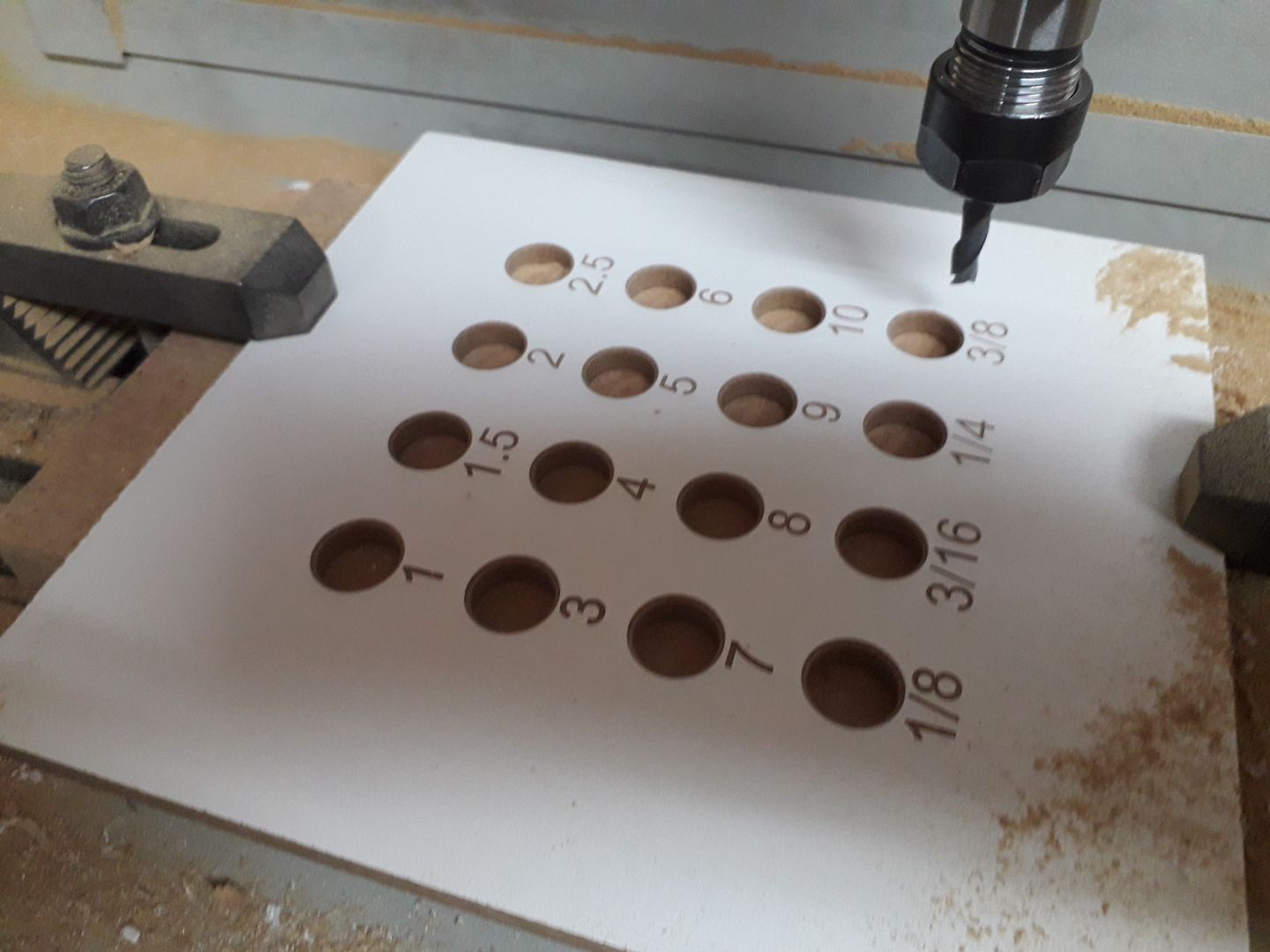

ER 32 and the Chinese collets are just in drilled holes a bit smaller than the collets in melamine faced MDF holes and raised off the base of the draw by a couple of battens  When I bought ER16 for the CNC I used the same 6mm melamine faced board but used the CNC to cut the holes and engrave the sizes  5C collets sit in a draw under the lathe in the bottom halves of their boxes so they don't rattle about  |

|

dalboy

E-xcellent poster

Posts: 235

|

Post by dalboy on Oct 10, 2022 8:16:29 GMT

Thank you all for some new ideas

jasonb I like what you have done with your lathe cabinet and fitted some draws between the uprights sure adds some extra storage space Guess that'll be tree wood. Be warned the stuff is now quite expensive. It doesn't grow on trees. Luckily I have two wood stores one mainly for flatwood and the other for turning blanks. I do tend to find old broken furniture to recycle the wood from but even that is starting to become harder to find as modern stuff uses veneered MDF and the like |

|

SteveW

Elder Statesman

Posts: 1,456

|

Post by SteveW on Oct 10, 2022 9:12:42 GMT

Luckily I have two wood stores one mainly for flatwood and the other for turning blanks. I do tend to find old broken furniture to recycle the wood from but even that is starting to become harder to find as modern stuff uses veneered MDF and the like Yep. I have a similar little cache of odd bits of treasured bits of old hardwood and it has nearly taken over. Whenever I start a new project I invariably go out and buy more. Anything left over get added to my treasure. The good news was I was able to make a new leg for a folding patio chair the other day. I even had to get my ER32 collets out to hold the router bit to machine/mill the circa nine inch slot and the lathe to make a 16mm flat ended drill to fit the round tenons of the chair frame. Also made a inverse 16mm core drill to clean up the damaged tenons. Had a lovely time. |

|

abby

Statesman

Posts: 927

|

Post by abby on Oct 12, 2022 14:23:41 GMT

Guess we all think alike , I built cabinet stands for my BCA jig borer and Pultra lathe. I used some 25mm marine ply which was surplus from another job. The drawers simply slide in on well waxed hardwood runners. There is room for more drawers but I haven't got round to making them yet.   Dan. |

|

|

|

Post by Jo on Oct 12, 2022 14:53:01 GMT

For my BCA collets I store them in a Bisley drawer unit which had some drawers missing. In the gap I have added a piece of plastic with tapered holes drilled into it. Into these the BCA collets are slid. Since making the collet slide I have picked up some more drawers for the Bisley but I find the collet drawer so useful I have retained it. For 30 Int tooling I am currently using on a job I store that in one of those 5C collet racks you can buy: You need to turn them alternatively at 90 degrees to get them to fit in each row otherwise they are too close  Jo |

|

abby

Statesman

Posts: 927

|

Post by abby on Oct 12, 2022 15:44:11 GMT

Hey Jo , I only have 5 original BCA collets and one that I made so I made a new spindle incorporating an ER 20 collet chuck.

My machine is dated 1942 and had been very badly abused. To date I have made a new X-axis leadscrew and nuts(the original had been jammed,then twisted until it bent)

I cut them with a square thread on an Emcomat lathe , cutting the 10 TPI female thread down a 5/16" hole was very interesting.

I also made new main bearings as the originals could no longer be adjusted.

Dan.

|

|

|

|

Post by Jo on Oct 12, 2022 16:48:51 GMT

Hi Dan, Mine is a Mk3. Some idiot ripped pieces out of the tee slots on the table and someone else sensibly made a replacement table top. It was well tooled up with two sets of imperial collets, boring head, wiggler etc. The leadscrews are good and made to read in modern measurements by a DRO    For metric holders I have been buying the blanks from RDG www.rdgtools.co.uk/acatalog/Tools_for_the_BCA_Jig_borer.html and just reaming them to fit the cutters shank and adding a grub screw for on the side to hold the shank. They do a rather nice M14 by 1 mm which allows you to use anything that fits on the smaller lathes with the same nose. And the boring head is very nice  Jo |

|

|

|

Post by jon38r80 on Oct 12, 2022 18:05:30 GMT

I have both ER25 and ER40 collets. The ER25 set I originaly bought to usewith a chuck and backplate on my first tiny lathe , a Taig/Peatol, and was very happy with it. When I got a Compact 5 I got a new back plate but found the 16mm max capicity too limiting so I bought the ER40 which I have collets up to 30 mm for.. I had to make the backplate for the ER 40 chuck out of a lump of cast Iron that I had. I made the wooden storage boxes, There are three, the first holds the ER 25 chuck backplates and collets. The ER 25 now gets mainly used for tool holding in a chuck with an MT2 spindle in my milling machine. The ER40 set was too big and heavy so it is split between two identical boxes. 3 to 16 and 17 to 30. All three boxes have lids slide into grooves to keep the swarf out when the set is being used and a slot to keep the approprate C spanner in down one side. ER25  IMG_3933 IMG_3933 ER40 - 3 to 16  IMG_3935 IMG_3935 |

|

abby

Statesman

Posts: 927

|

Post by abby on Oct 13, 2022 14:34:54 GMT

Jo ,

Strangely enough although my machine had been abused the 3 slotted table is pristine apart from 3 equi-spaced holes tapped 2BA.

I fitted adjustable stops for the x-axis table movement which is great for repetition work, and a simple dro on the x-axis which is useful for drilling accurately spaced holes such as connecting rods,

but cannot see how to instal for the y-axis,

Would you mind showing me how you installed yours ?

Dan.

|

|

|

|

Post by Jo on Oct 13, 2022 15:17:33 GMT

Its fairly easy to fit not like the joys of working up the Z axis. The scale is just spaced off from the Y axis ross slide and the read head on the left hand end of the table.  Jo |

|

abby

Statesman

Posts: 927

|

Post by abby on Oct 14, 2022 15:06:49 GMT

Thanks Jo, that does look easy enough, I was worried that only supporting one end would not be rigid enough for accurate readings

Dan.

|

|