Greg

Involved Member

Posts: 84

|

Post by Greg on Jan 3, 2024 3:48:17 GMT

Hi, So I don't currently have a slitting saw, so thought I'd buy some, but I wasn't sure what thickness is best. So I was after some advice. I was going to buy them from a company called ctc. prices are good and quality of previous cutting tools e.g. end mills has been good enough for me as a hobby machinist. Thinner sounds better because less material is lost, but suspect they become more fragile. Some of them seem very thin e.g. 0.2mm thickness. Surely these would be fragile? They sell carbide and hss. Which is best? How thin should I go? i was thinking perhaps 40 x 13 x 0.5 72T carbide www.ctctools.biz/carbide-slitting-saw-metric-1pc-h93/hss www.ctctools.biz/hss-slitting-saw-metric-1pc-h87/Thanks, Greg |

|

jasonb

Elder Statesman

Posts: 1,236

|

Post by jasonb on Jan 3, 2024 7:28:26 GMT

The thinner they get the more they are likely to deflect giving a wonky cut that then needs more material machining off to get a flat surface. Also what are you cutting? There are generally two types those with lots of teeth and those with less. The ones with a lot of teeth should only be used for shallow cuts such as slotting a screw head or cutting thin material a sthe gullet between teeth soon fills with swarf on deeper cuts. Ones with less teeth should be used on deeper cuts so they clear the swarf. I see CTC only seem to list the ones with a lot more teeth which have limited use If I only had one saw it would be 80mm dia, 32T and 1mm thick and would be OK for deeper cuts also the occasional shallow one. This sort of thing which is from ARC, Aussee probably do the same.  If you have not use dthem before don't fall into the trap of running them too fast and blunting all the teeth. Depending on diameter 100rpm or even less. |

|

Greg

Involved Member

Posts: 84

|

Post by Greg on Jan 3, 2024 9:01:45 GMT

Thanks Jason, you were very helpful. Ausee machine tools do 40T slitting saws in thicknesses from 0.5mm to 1.00.

I was buying some other stuff from CTC, which is why I thought I get a slitting saw from them, but I won't bother. I'll buy from the from Ausee. Thanks for the suggestions.

Greg

|

|

jasonb

Elder Statesman

Posts: 1,236

|

Post by jasonb on Jan 3, 2024 9:42:52 GMT

Just watch out as the 40T are only 50mm dia so teeth will have finer tpi than 40T on an 80 or 100mm blade

|

|

jem

Elder Statesman

Posts: 1,075

|

Post by jem on Jan 3, 2024 17:04:03 GMT

Slitting saws are generally for slitting, so it depends on what size slit you want. the diameter of the saw needs to be big enough to cut the depth of slit you want,Remeber that the arbr gets in the way, so a useful saw would be one of say 120mm dia and 1 or 2 mm thick. these saws do need plenty of lubrication when cutting. All my saws are High speed steel, Which seems fine for me.

best wishes

Jem

|

|

jasonb

Elder Statesman

Posts: 1,236

|

Post by jasonb on Jan 4, 2024 7:32:09 GMT

Don't know what type of machine you use but be wary of using too large a diameter saw in a electronically variable speed machine. The usual benchtop hobby machines lack grunt as the speed comes down and a 120mm saw would want to be running at 80rpm or less which may well just stall the spindle. less of an issue on old belt or geared machines as their motors are running at optimum speed all the time.

|

|

|

|

Post by Nigel Bennett on Jan 4, 2024 19:10:12 GMT

Grandmothers and eggs and all that, but you need to run them fairly slowly! I recall one doleful chap who asked why all the teeth on his pinged off; he was treating it like a woodworking circular saw at umpty thousand RPM. So take care - I run mine as slow as I can get if they've any size about them.

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,988

|

Post by JonL on Jan 5, 2024 17:26:41 GMT

Well I've learned something today. Handy as I've got some slitting to do shortly. Less speed it is!

|

|

jasonb

Elder Statesman

Posts: 1,236

|

Post by jasonb on Jan 6, 2024 7:24:48 GMT

Just think of the saw like a piece of steel in the lathe, what would you turn that at when using HSS lathe tools.

If we said a max of 30m/min or 100ft/min in old money then an 80mm saw wants to run at no more than 120rpm, 100mm saw @ 95rpm and 120mm saw @ 80rpm

At those speeds a direct drive brushless hobby machine may stall as low reves and the dia of the cutter need more grunt that the motor can supply when running so slowly. So a bit of overspeeding will have to be used

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,858

|

Post by uuu on Jan 6, 2024 8:56:01 GMT

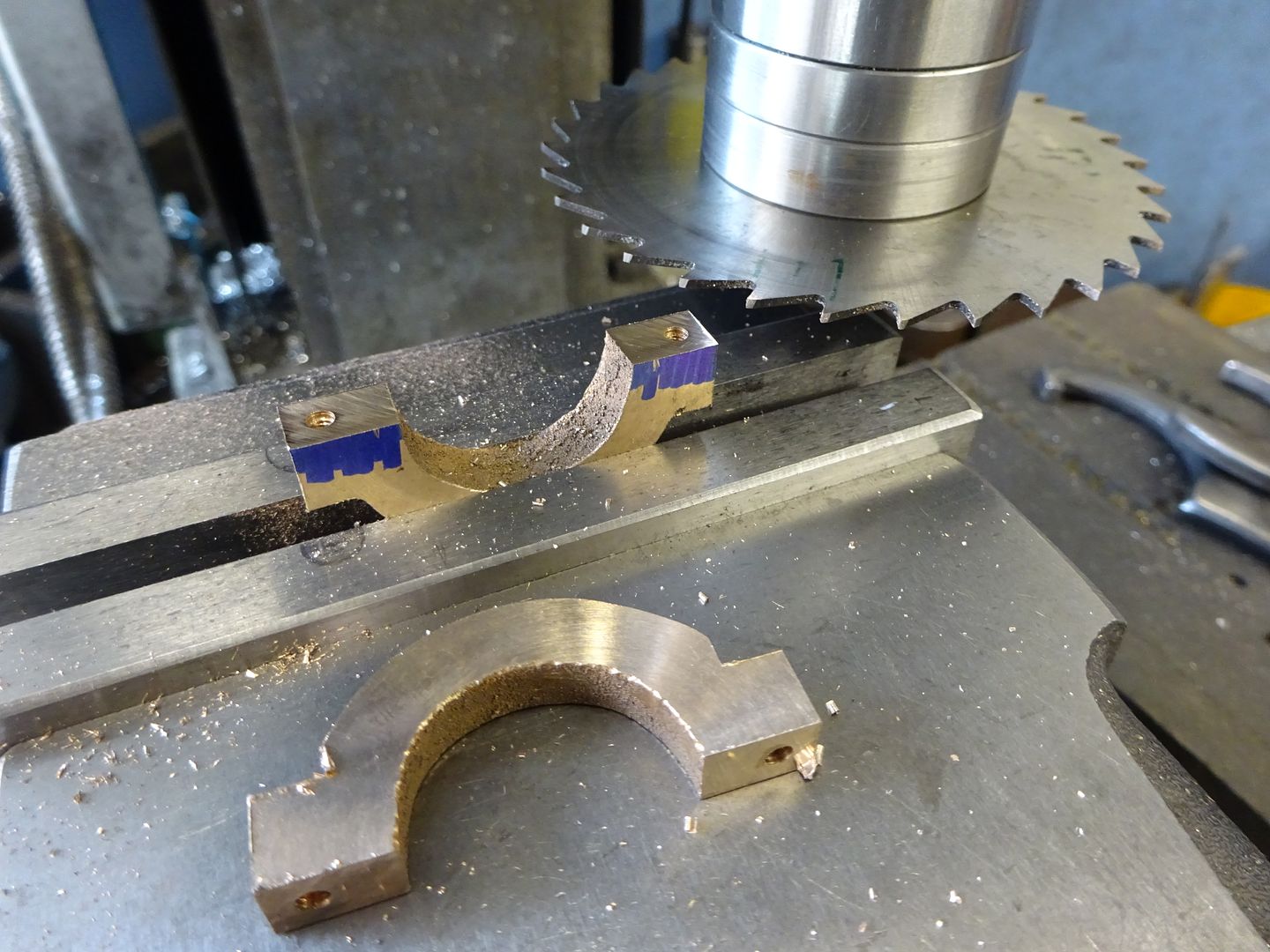

When John and I were cutting Clupet piston rings at the Pump House, we found a thin saw deflected off line if we tried to take the cut in one go. Taking a shallow cut first created a trough to guide the cutter on the second go, and produced a straight result.

Wilf

|

|

|

|

Post by Roger on Jan 20, 2024 9:03:18 GMT

All slitting saws deflect given half a chance. I take multiple shallow cuts which reduces the tendency. I use the thickest possible for the job, and the smallest diameter so it's less flexible.

I have a whole range of thicknesses and diameters to handle the variety of situations that need slitting.

|

|

millman

Part of the e-furniture

Posts: 325

|

Post by millman on Jan 20, 2024 9:32:35 GMT

I agree totally with Roger, given half a chance they will wander all over the place, if possible I tend to use a thin side and face cutter as they tend to be a bit stiffer.

|

|

|

|

Post by chris vine on Jan 23, 2024 21:45:51 GMT

I had that slitting saw wandering off-line when I made my clupets too - and I thought it was just me with a machine which wasn't set quite square.

Did exactly what you two experts recommend, and put a shallow cut first which the saw can keep straight, then did the deeper cut guided by the shallow one.

Great minds think alike and all that!

Chris.

|

|