jl

Member

Posts: 4

|

Post by jl on Oct 23, 2024 20:31:21 GMT

When I do syphons and the like, I put the nut and cone onto the pipe and then bell the end of the pipe out slightly (and just enough) so the cone can't slip off or get nudged during silver soldering, also means things can be arranged so gravity works with you (if pre-placing silver solder on the job etc). I imagine it would also reduce the chance of blocking the pipe, it works for me anyway. A moment's work to neaten up afterward with a needle file but only if necessary, leaving the sealing face quite untouched. I also like to dispense with the short stub pipe that comes with the gauge and connect the syphon direct. JL  |

|

jasonb

Elder Statesman

Posts: 1,246

|

Post by jasonb on Oct 24, 2024 6:21:46 GMT

The difference with caulking and just a soft soldered joint is that the caulk is not taking any real load as the rivits do that. On a soldered joint between nipple and pipe if the solder softens (not even to melting point) then the two can be pushed apart by the pressure. If softsolder was that good then we would be using it to make our boilers without rivits.

Think of it like joining the traction engines cylinder to the boiler, you use a sealant and studs. Would you omit the studs and just hope the sealant held the cylinder in place or would you stick the pipe and nipples together with just sealant?

I have always silver soldered mine if they are going to be under pressure. Soft is Ok for feed water and the like.

I also prefer to feed in the solder rather than place it on the joints. Was taught at school that for fine work a length of solder can be hammered flat and then cut into 3 or 4 strips with tin snips, just use a clean hammer and surface so you don't embed dirt into the solder.

|

|

|

|

Post by Jo on Oct 24, 2024 20:03:26 GMT

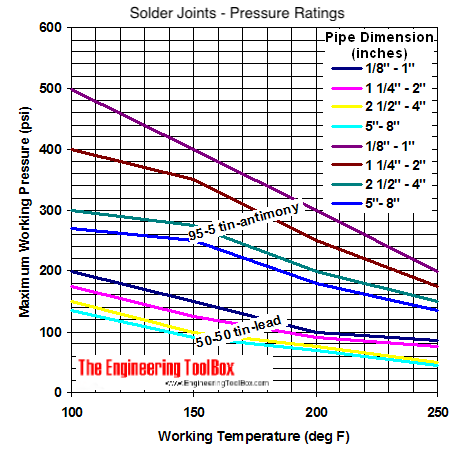

Hi Jl, yes the Syphon joint is one of the most horrible challenges of fitting out of a boiler. The design of the nipple/pipe joint can make life easier/harder to join. I totally agree with Roger on technique  The difference with caulking and just a soft soldered joint is that the caulk is not taking any real load as the rivits do that. On a soldered joint between nipple and pipe if the solder softens (not even to melting point) then the two can be pushed apart by the pressure. If softsolder was that good then we would be using it to make our boilers without rivits. Think of it like joining the traction engines cylinder to the boiler, you use a sealant and studs. Would you omit the studs and just hope the sealant held the cylinder in place or would you stick the pipe and nipples together with just sealant? I have always silver soldered mine if they are going to be under pressure. Soft is Ok for feed water and the like. I also prefer to feed in the solder rather than place it on the joints. Was taught at school that for fine work a length of solder can be hammered flat and then cut into 3 or 4 strips with tin snips, just use a clean hammer and surface so you don't embed dirt into the solder. Lots of stuff there Jason. Fundamentally the temperature of the syphon joint in a standard Locomotive Boiler will not cause the failure but implementation of the design will. I have low temperature nipple joints operating at over 250 PSI on my Aircon and they are not silver soldered. Here is a chart of standard joint safe pressure ratings and the types of soldering medium required :  I am encouraged that the technology is capable but forever question: do us amateurs build our stuff to these standards? Jo |

|

jasonb

Elder Statesman

Posts: 1,246

|

Post by jasonb on Oct 25, 2024 6:37:12 GMT

As you know Jo it is not just the pressure of the steam.

At 100psi a quick look at some steam tables will show that it reaches 164deg C, Push that to the max for copper of 120psi and you are at 172deg C. If a steel boiler then you would be even higher.

Even forgetting steam temp and just taking 100deg C which is about 210Deg F on your chart the 50/50 lead is only just about touching the 100psi line for the smallest pipe dia range..

Typical soft solder melting range starts at 183deg C. So you are getting very close to melting. Even if you don't reach that there is a "plastic" state where the solder becomes softer and weaker and could start to creap over time. Maybe the pressure gauge end won't get anywhere near that temp but the other end if it is on a shared manifold may do.

I suppose there is a reason model engineers have always silver soldered their Nipples as that is what I have always read and seen done. Anyone else here soft solder their pipework which is under (reasonable) pressure with soft solder?

If don't know your particular air con or which joints may be soft soldered byt the Refridgeration and HVAC industries hard solder a lot of their joints, just take a look at CUP they have sections for those trades.

|

|

johan

Seasoned Member

Posts: 121

|

Post by johan on Oct 25, 2024 8:54:25 GMT

I had used this silver bearing soft solder for the piping of the oscillating engine on my first gauge 1 loc. Solder with a melting point of 217 °C. Simple pot boiler, joints out in the open air. Piping came apart after a couple of years, the joint at the engine just separated, bright solder coated all the way. I did it again with the same solder as I cannot silver solder on top of the soft solder. But I'm not going to do this for my next loc.

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Oct 26, 2024 21:46:30 GMT

Success! Partially I think due to the advice on this forum, and some experimentation, I managed to do all four remaining nipples with 100 percent success. Thank you all. One other thing I did was put the solder on the pipe under the fitting (without touching the solder to the fitting at all) then playing the heat up the pipe towards the fitting, as soon as the solder crept up to the fitting it wicked beautifully while still being quite controllable. It was much easier to under deliver that way. I tried wrapping the solder round a small drill bit first but it was obvious it was going to really badly overload. I think I need to get some of the paste/thinner wire mentioned above before any more brass surgery.

Thank you all.

|

|