ace

Statesman

Posts: 528

|

Post by ace on May 31, 2007 23:23:58 GMT

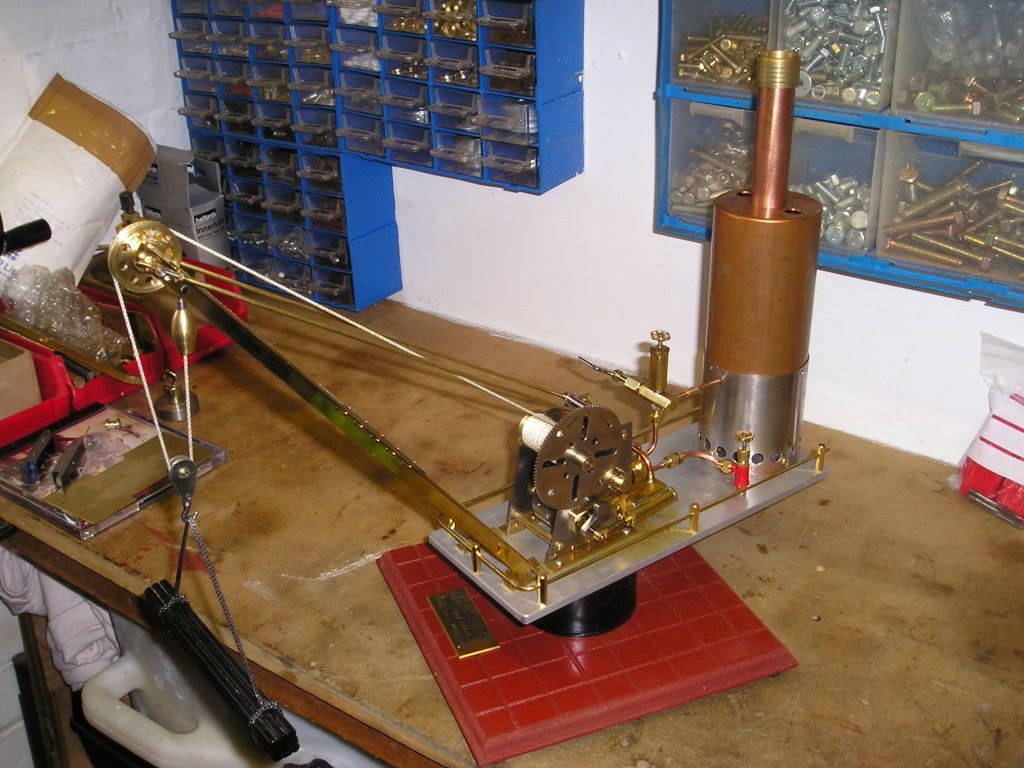

Hope there's someone out there that can help. I wish to complete one of my projects (Hercules platform crane, build date June 2005) but I am having trouble silver soldering the boiler. This is my second boiler as the first went terribly wrong and after two attempts to correct my work, it met with the 14lb sledge hammer  . does anybody wish to tackle this job for me, I am willing to pay you for your time. I live in the Manchester area and would bring or post the boiler to you. I am practicing to silver solder but only on smaller things for now. The boiler is 2 1/2" x 4 1/4" c/w three bushes, steam pipe and chimney. thanks ACE    |

|

|

|

Post by spurley on Jun 1, 2007 7:42:23 GMT

Hi Ace

Sent you a PM.

Cheers

Brian

|

|

paul

Member

Posts: 8

|

Post by paul on Jun 1, 2007 9:59:46 GMT

Nice one Ace - your boiler looks about the same size as mine (but infinitely better made!) and I had the same problem i.e. the amount of copper quickly conducts away all the heat needed for silver soldering if you're just using a regular DIY blow torch. Once I got access to a brazing hearth the problem disappeared  Personally I now find silver soldering small parts even with a blow torch easier and neater than soft soldering - probably because the solder is a known quantity unlike some of the soft solders and I know what flux to use etc I think your crane is great - post some more pictures (and when the boiler's finished maybe a video!). Cheers Paul. |

|

ace

Statesman

Posts: 528

|

Post by ace on Jun 27, 2007 22:08:16 GMT

Job sorted.

Thanks

ACE

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jun 28, 2007 2:47:48 GMT

G'day Ace.

Getting the heat into the job is a problem the simple books don't tell you about. In equipment lists they just mention a hobby torch; might as well use a match!

I did my first job on the gas stove for general heat to the boiler with the torch the joint area. It worked well until one time I put the torch on the bench.You can guess the rest. Thankfully I had a dampo cloth handy and could smother the burning varnish and then was able to sand most of the scorch marks out of the oak cupboard door. Funny, SWMBC made no comment, was it because I was building the engine for my grandson?

I now do silver brazing out on the barbeque with two torches, one a moster fed from a 20kg gas bottle. BTW the old pundits used to make little hearths for their jos to keep the heat in or bury them in charcoal.

Regards,

Ian

|

|

ace

Statesman

Posts: 528

|

Post by ace on Jun 28, 2007 7:47:09 GMT

Hi Ian I have done no real silver brazing until this job, tried a few times on small bits that didn't matter what it looked like. My first attempt on the (1st) boiler started well on the base with a very smooth fill in the joint, then the most important joint the top as this is what you will see went drastically wrong I just couldn't get enough heat at once to braze all the bushes and flue at once and the solder ended up in blobs.  I have since built a brazing hearth from Skamolex insulating plates (from Chronos), what a difference it makes. I did a much better job second time round. I am trying to get the cam-corder set up so I can show all the end product running on her own steam. I still read up on the brazing subject to get tips and advice etc. ;D Steve |

|