|

|

Post by ettingtonliam on Jan 19, 2009 9:50:04 GMT

Hi

I bought a Mk 1 Clarkson T&C grinder a couple of years back, but am only just getting round to setting it up. it was running on single phase when I got it, but I've since lost my notes re the connections to the motor. Its a 0.5hp AEI motor, marked 220/240 -400-440. There are 6 connections in the terminal box, marked A1 C1 and B1 on the top row, and C2 B2 and A2 on the bottom row. The diagram inside the lid shows A1 linked to C2, C1 linked to B2 and B1 linked to A2 in the 'Low Voltage' set up, but doesn't indicate which terminals the incoming supply is connected to. A 25uF capacitor has been connected to terminals B2 and A2.

Where do I connect live, neutral and earth?

Richard

|

|

davediy

Active Member

Never ending projects

Never ending projects

Posts: 38

|

Post by davediy on Jan 19, 2009 11:38:01 GMT

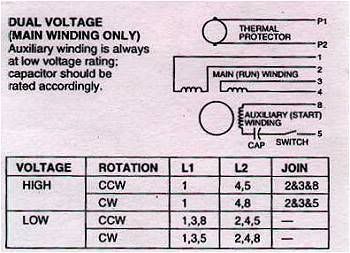

Hi I think the diagram shows the wiring for low voltage in three phase configuration not single ,but to be safe side Have a look at this site . www.firstelectricmotor.com/motor_connections.htmand see which one matches yours. Look at the duel voltage single phase 6 wire link. this is what I would expect to see not the wiring you mentioned L1 is live L2 Neutral . it shows live to numbers 1,3,5 and neutral to 2,4,8 and cap between 5 coil & 6 also Cw is clockwise CCw counter clock wise. The diagram you mentioned is similar the duel voltage 6 lead 3 phase link diagram. This shows 1 and 4 linked as yours 2 and 5 and then 3 and 6 in the delta configuration. This is not suitable for single phase home style wiring You may have to remove the links you have and wire as the diagram on the duel voltage 6 lead single phase link instead however I wouldn't recommend messing with the motor if you don't know what your doing and find a electrician and get them to have a look  I'm also assuming A1=1 B1=2 C1=3 A2=4 B2=5 C2=6 be safe hope this helps ;D Dave PS Earth normally is connected to the chassis of the motor |

|

|

|

Post by ettingtonliam on Jan 19, 2009 12:10:44 GMT

Dave

You are right, I don't know what I'm doing, which is why I asked. I know it was running when I bought it, and that was with the links in the present arrangement, so really its a choice of C2, B2 and A2 for the live and neutral connections. Thanks for the link, but it leaves me no wiser, so I think a call to my local motor rebuilder is on the cards.

Thanks for the help.

Regards

Richard

|

|

davediy

Active Member

Never ending projects

Never ending projects

Posts: 38

|

Post by davediy on Jan 19, 2009 12:32:22 GMT

Sorry I couldn't be more help.  But I think your doing right to take it to somebody who knows what they are doing. Posted the image on photo bucket for you  let us know how you get on In case I was wrong  dave |

|

|

|

Post by Staffordshirechina on Jan 19, 2009 12:48:15 GMT

Something about this doesn't sound right.

Is the motor a single phase motor or a three phase motor?

What exactly does it say on the motor rating plate?

Just because it says 'dual voltage' it doesn't mean it can be run on single phase.

It means it can be connected to three phase in two different ways.

Was the previous owner using an inverter to run the machine?

Les

|

|

davediy

Active Member

Never ending projects

Never ending projects

Posts: 38

|

Post by davediy on Jan 19, 2009 13:29:58 GMT

Something about this doesn't sound right. Is the motor a single phase motor or a three phase motor? What exactly does it say on the motor rating plate? Just because it says 'dual voltage' it doesn't mean it can be run on single phase. It means it can be connected to three phase in two different ways. Was the previous owner using an inverter to run the machine? Les I do think something is a bit odd about this motor described and it dose sound like a 3 phase motor from the links he described. I don't know why I didn't think of an inverter being used. I got thrown by the capacitor being present and being used on single phase it just didnt occur to me  Any chance you can supply a picture of the plate for us ettingtonliam as well as a pic of the links you mentioned. If it is 3 phase you will have to use a inverter or change the motor for a single phase one.  Dave |

|

|

|

Post by ettingtonliam on Jan 19, 2009 14:25:19 GMT

Hi

When I saw it running, it was definitely plugged into a normal 13A domestic socket, so I assumed that was a single phase supply, and the guy told me it had been modded with the capacitor 'by a professional' to run on single phase. If you connect single phase to a 3 phase motor, does it run at all? Like a 3 cylinder engine firing on 1 cylinder? I will photo the plate, but my attempts to post photos in the past have failed. I don't want to go down the inverter route as all the other motors are single phase, so it is increasingly looking like a new single phase motor.

Regards

Richard

|

|

|

|

Post by baggo on Jan 19, 2009 14:48:30 GMT

Hi Richard,

it probably is a 3 phase motor as you can get dual voltage models with only 6 connections. You can also run a 3 phase motor from a single phase supply by feeding one of the windings with a suitable capacitor. It looks as though that is what the 'professional' did. Getting the right value for the capacitor takes a bit of experimentation and the motors often run at reduced power.

To get it to run you would connect live and neutral to A1 and B1 or even A1 and C1. I'm not sure if that would affect the direction of rotation though.

John

|

|

|

|

Post by Staffordshirechina on Jan 19, 2009 15:22:26 GMT

Running a 3 cylinder motor on 2 cylinders is not a good way of doing things! As Baggo says, finding the right capacitor is not easy either. At 1/2 hp, you can probably find another single phase motor easy enough unless it has a fancy mounting and probably cheaper than an inverter.

If the machine were a lathe or mill then an inverter would be a good idea for speed control but for a T & C grinder it is irrelevent.

Les

|

|

davediy

Active Member

Never ending projects

Never ending projects

Posts: 38

|

Post by davediy on Jan 19, 2009 15:24:00 GMT

If it is a 3 phase motor converted to run on a single phase 240v supply as you said. then the plate will only show what it once was originally. A 3 phase motor will only run at about 75% of its rated Hp on single phase supply and tends to run unbalanced making noise and vibration compared with a 3 phase supply. Saying that seeing though. As you have actually seen it running shows they got it right.  Is there any chance you can ask the person you got it off in case they might remember which wire to connect to what or give the motor rewind people a bell might save you a trip. dave |

|

|

|

Post by ettingtonliam on Jan 19, 2009 16:46:13 GMT

Hi

Thanks for all the advice gents. Unfortunately, there is no chance that the vendor will remember how it was wired, probably won't even remember selling it to me. I can live with it being down on power, I'm not exactly going to be pushing it to its limit on production work, and if the vibration is too much, then it will just have to be a new single phase motor, but it seems from what you have said, especially John, that provided the 'professional' knew what he was doing sizing the capacitor, this motor might just work. Recapping, before I wire it up and pluge the country into a blackout, there are 6 terminals, top row A1, C1, B1, bottom row C2, B2 and A2. A1 links with C2, C1 with B2 and B1 with A2. The capacitor is linked to B2 and A2. John's suggestion is to connect to A1 and B1, the 2 end terminals on the top row. because these are linked to the bottom row, this is the same as connecting to the end 2 terminals on the bottom row. The capacitor is linked to an end and middle terminal, hence is connected to either the live or neutral. does it matter which? Sorry to be slow on the uptake, but I just have a blind spot with matters electrical.

Richard

|

|

|

|

Post by baggo on Jan 19, 2009 17:34:55 GMT

Hi Richard, connect the neutral to A1 and the live to either C1 or B1. Apparently the motor will run in either direction depending on whether you use C1 or B1 so you'll have to try both until the motor runs the correct way! Apparently, this method is known as the Steinmetz connection and has been around for some time. As mentioned, it is a very inefficient way to run the motor. Starting torque is poor and the running torque is only about 70% of what it should be. For a tool and cutter grinder this may not be much of a problem. It would still be better to try and source a single phase motor when you can. There's a picture of the Steinmetz connection here: www.plctalk.net/qanda/uploads/steinmetz.jpgJohn PS don't forget to connect the earth to the motor chassis! |

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jan 19, 2009 21:14:35 GMT

G'day Richard

I'm rushing out of the office on a job so can't spend time with you right now.

You have all you need, a 3 phase dual voltage motor and a 25mF capacitor. Even most of the connections are made for you.

Send me a PM and later today I will draw you a diagram.

Baggo's information is the most helpful, IMHO pay less regard to the rest.

Regards

Ian

|

|

|

|

Post by ettingtonliam on Jan 20, 2009 8:24:33 GMT

Thanks very much for the info everybody. I'll try Baggo's method tonight!

Richard

|

|

|

|

Post by ettingtonliam on Jan 20, 2009 13:41:22 GMT

Baggo, Ian

Went home at lunchtime, connected it up, terminals A1 & C1 and it starts, runs, doesn't vibrate, is no more noisy than would be expected. Success! Addmittedly, that was running light, not even with the belt on, and only for a few minutes, but I'm encouraged now to make a 'proper ' job with a gland on the terminal box, and terminals on the wires. Thanks again for the advice.

Last question - the capacitor (plastic casing) has 2 wires around 15" long, and isn't fastened to the motor in any way, except by the wires. I intend to strap it to the motor, probably to the lid of the terminal box, to make a neat job. Can I trim the capacitor wires to length, or is their length in any way 'tuned' to performance of the capacitor?

Regards

Richard

|

|

|

|

Post by baggo on Jan 20, 2009 15:14:10 GMT

Hi Richard,

The length of the leads won't make any difference in this case. Just make sure all the external leads are well insulated. Might be worth running the two capacitor leads through a bit of sleeving for extra protection.

One point if anyone else trys this. Make sure the capacitor is designed for continuous use. There are two sorts of capacitor available for motor use - Running capacitors and Starting capacitors. Running are designed for continuous use (as in this case) but Starting are only designed for brief intermittent use (i.e. just for starting the motor, they are then disconnected by a centrifugal switch for example). If you try using a starting capacitor for this use it will eventually go bang!

John

|

|

|

|

Post by ettingtonliam on Jan 20, 2009 16:05:17 GMT

John

Now you've got me worried again! How do I tell if its a capacitor suitable for continuous use?

Richard

|

|

davediy

Active Member

Never ending projects

Never ending projects

Posts: 38

|

Post by davediy on Jan 20, 2009 16:34:38 GMT

Hi

I'd say don't worry as it was done professionally you should have no trouble. ;D

As you said there was little vibration and no more noisier than you expected so it sounds like its correctly converted and working properly and as your not likely to be running a grinder all day anyhow only on when your actually using it.

just tidy up the wires insulate where you can

Dave

|

|

|

|

Post by baggo on Jan 20, 2009 17:36:27 GMT

Hi Richard,

As Dave says, don't worry about it. It almost certainly will be the correct type as it's obviously been running for some time. I just made the point in case anyone else tries it.

John

|

|