|

|

Post by andrew on Mar 14, 2006 2:07:18 GMT

I'm at a loss trying to think of how one could have a suspension system on a steam locomotive with coupled drivers. I've tried to search for information on the topic, but have come up empty handed.

Could someone point me in the right direction?

Thanks,

Andrew

|

|

|

|

Post by burnettsj on Mar 14, 2006 9:09:59 GMT

What are you stuggling with?

suspension is essential for good adhesion

|

|

|

|

Post by jgb7573 on Mar 14, 2006 10:08:11 GMT

I'm not entirely sure I understand the question either. However, what happens on most engines I've seen is as follows.

Each coupled wheel is idividually sprung. It has one or more springs acting on the axle box, which slides up and down in the horn.

Each pair of wheels on a common axle can move up and down within the horns. Clearance between the back of the wheels and the axle blocks mean that the axle can tilt relative to the horizontal. For instance the left hand wheel can drop while the right hand wheel on the other end of the axle can rise. This is aided by a radius included on the flanges of the axle boxes where they bear against the outside of the horns.

For pairs (or more) of wheels coupled together by rods, you might think they have to move toggether because of the rods holding them together. However, it doesn't work like that as although the rods are a fixed length, there is clearance in the bearings in the system. So there is clearance between the axle and the axle box. Betwen the axle box and the horns. And between the crankping and the coupling rod brasses. These clearances can add together to provide enough extra 'length' between the wheels to allow one wheel of a coupled pair to drop whilst the other rises.

As I say, I'm not sure if this is what you're after, but this is my understanding of what happens. As one of the old boys at my club is wont to say, you can't build a 'tight' steam engine to I/C tolerances and expect it to work well. A steam engine needs a bit of 'slop' to run freely.

|

|

|

|

Post by burnettsj on Mar 14, 2006 10:20:21 GMT

Each pair of wheels on a common axle can move up and down within the horns. Clearance between the back of the wheels and the axle blocks mean that the axle can tilt relative to the horizontal. For instance the left hand wheel can drop while the right hand wheel on the other end of the axle can rise. This is aided by a radius included on the flanges of the axle boxes where they bear against the outside of the horns. My experience/knowledge is that the tilting clearance is only the radius on the flange of the axlebox box. Clearance between the wheels and axleboxes does two things: - wear out your rod bushes faster (due to the side-side movement of the axle) and allow the loco to go around tighter curves. As a matter of interest - a full size manor has 0.010" clearance between the axleboxes and wheels. Having said that, the whole engine needs to be built to tight tolerances to have a single item tight. Once upon a time an industrial engine had it's rod bushes done to GWR tolerances and after refiiting the wheels wouldn't go around! |

|

|

|

Post by chris vine on Mar 14, 2006 10:39:55 GMT

on a 6 coupled engine or more, where the coupling rods extend over more than two axles, there are pin joints to allow one axle to move vertically independantly of the others.

This feature is never included on "toy" model locomotives.

Chris

|

|

|

|

Post by havoc on Mar 14, 2006 20:27:58 GMT

Oh yes, I have seen gauge1 engines with this. But the "slop" principle is always used.

|

|

|

|

Post by steammadman on Mar 14, 2006 21:44:53 GMT

If you look back through the volumes of "our bible", the Model Engineer you will find two or three explanations of locomotive suspension/ adhesion, i think the master himself "LBSC",

wrote a bit about it many years ago,still worth reading, and, i beleive Jim Ewins had a bit to

say on the matter when he was writing about his 9f .

|

|

JohnP

Hi-poster

Posts: 186

|

Post by JohnP on Mar 14, 2006 22:47:28 GMT

The other thing to remember is that as one axle moves up, you'd expect the adjacent coupled axle to get pulled towards it. Whilst this is true, it's amazing how small this effect actually is. You can do the sums quite easily, it's Pythagarus' theorem. If the axles were 6 foot apart and one axle moved 1 inch up (or down) relative to the other then the difference in length that you'd need is only 6.94 thou!

Cheers,

JohnP

|

|

|

|

Post by andrew on Mar 15, 2006 7:06:24 GMT

Sorry for the vague post, and possibly misusing terms...I was hoping someone could point me to some online material, not necessarily try to teach me over the internet.

I'll try again. ? - denotes possible missuse of terms

Consider a 4-8-4. There are 4 axles rigidly? coupled? together by the side? rods. When the first driver encounters an undulation in the track (bump or dip), how can it possibly follow that profile without unloading another driver or losing contact with the rail? I haven't seen a detailed schematic of a locomotive suspension of this sort, and can't seem to find much information online...I'm sure it is there, but it is hiding from me.

Thanks,

Andrew

PS, I have read the replies above, and it is helping me understand...but I want MORE! ;D

I'll have to check on availability on Model Engineer backissues in my area...

|

|

|

|

Post by steamjohn248 on Mar 15, 2006 7:24:38 GMT

Re steam loco tolerances.

Some of you may find this amusing. A very senior and experienced fitter on a full size railway I drove, on always carried a very battered and unreadable 6 inch rule in his overall pocket. I pulled his leg about it one day, saying what possible use was it as the figures had long since worn away and anyway it was bent and mangled.

In his own colourfull use of English, learned no doubt in the works,probably fifty years ago, he fished the battered ruler out, held it under my nose and in quite unprintable prose said, See that ########, well if you canna get that into owt, its too.######### tight! (And what he doesn't know about about steam locos aint worth knowing)

Steamjohn

|

|

|

|

Post by burnettsj on Mar 15, 2006 8:29:31 GMT

Personally, I don't know of any online material. Had a quick search and there's some pictures on this page (admittedly of an 0-6-0): www.saunalahti.fi/animato/3003/666.htmlAs you can see each axle can move up and down the frame in the horns. Although the coupling rods connect all 3 wheels (per side), as Chris has stated, the rods are jointed (called a gradient pin) so that only two wheels are "rigidly" connected, so each wheel can move independently. The gradient pin can be just seen behind the bush for the driving axle crank pin. In the case of a 8 coupled engine there would be 2 gradient pins per side. In the case of a 10 coupled engine there would be 3 gradient pins per side. www.92214.co.uk/ has some good photos of the coupling and connecting rods - look under "Early Days (Butterley)" and the last photo. Hope this helps. |

|

|

|

Post by havoc on Mar 15, 2006 19:19:15 GMT

And if you would have a loc where one of the drivers can slide left-right in its bearing (to go better round the corner) then they would fit an universal bearing at that place.

|

|

|

|

Post by chris vine on Mar 16, 2006 16:15:18 GMT

Hi,

Not too sure about this left-right movement. The railway companies usually went to great lenghts to try to prevent this by accurate fitting of the axleboxes in the horns and also by self adjusting horns in some cases.

Once there is wear there, there is a bad case of knocking from the huge piston thrusts. This will wear the wheels, fatigue the frames and even, I suspect, the boiler. .....

Chris.

|

|

|

|

Post by havoc on Mar 16, 2006 19:32:23 GMT

Oh yes, they did use that. Things like radial axleboxes etc where commonly used on 4 couplers and larger. I'll try to post a pic tomorrow of such an arrangement.

|

|

|

|

Post by Richardw on Mar 17, 2006 8:14:19 GMT

This is getting away from the original question but some Railways did deliberately introduce left-right movement, the early Great eastern N7 0-6-2 tanks had lateral suspension for the front axle box using coil springs and had a hinge in the vertical axis for the front coupling rods. I don't think the LNER used this on the later builds but I have seen photos of the early engines with the hinge.

Regards

Richard

|

|

|

|

Post by chris vine on Mar 17, 2006 11:32:52 GMT

Hi Havoc

I was thinking at rightangles. I was looking at the loco from the side and thought your left right meant back and forwards. That is what would give rise to a lot of knocking.

Ha Ha at me!,

Chris.

|

|

|

|

Post by havoc on Mar 18, 2006 12:36:31 GMT

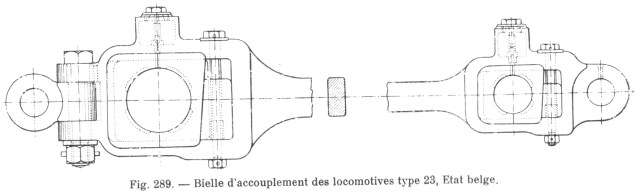

Took a day longer than expected. But here is a drawing of the coupling rod from the type 23 (later type 53) loc of the belgian railway. This was a 4-axle shunting engine that could run in 100m radius. So the last axle had a lateral displacement of 14mm (both sides) and the front axle a displacement of 4mm. So the coupling rod had an articulation in both planes to the last axle and in a slingle plane to the front axle.  Here's a pic of what it looked like: www.bfoto.be/historie/hlv/53.htm |

|