Post by AndrewP on May 15, 2010 23:13:24 GMT

Having decided that the plain black buffer beam of my little 3 1/2" gauge Fowler looked naked, and desperate to have some progress on something for our open day, I made some buffer sets.

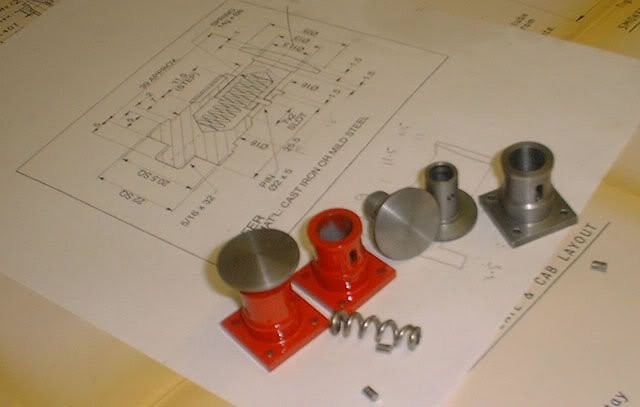

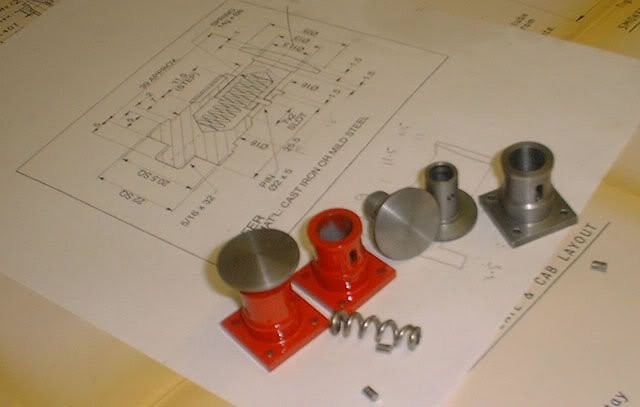

Not having any provision for mounting I wanted a design that could just be bolted to the beam through a square backed stock so copied the set from the Q1 currently running in Model Engineer. Having worked out the dimensions missing from the drawing so that they could actually be made and searched without success for the words to go with the drawing I just dived in anyway.

Turning the stocks from 1" square on the Boxford, first time I've used the fixed steady. Parting was interesting.

Turning the curve on the buffer head using Baggo's excellent tip, very roughly wound spring against saddle from tailstock and saddle disconnected from leadscrew.

The heads were turned from 1" en8 on the Boxford and just this last bit done on the little Chinese jobby, that topslide is a joke and seldom mounted.

A finished pair - I made 5 (doesn't everybody start an extra one to allow for oopsies?) and they all came out

Fitted and looking good imho. Buffer beam drilled and tapped 6ba with reduced head bolts, except one is a dummy because the hole has half of my 6ba taper tap in it. I bent up some links from 1/8" bms for the coupling.

After I had finished them the words appeared in the Q1 series, except the design had changed and was now fixed from behind the buffer beam - oh well

Not having any provision for mounting I wanted a design that could just be bolted to the beam through a square backed stock so copied the set from the Q1 currently running in Model Engineer. Having worked out the dimensions missing from the drawing so that they could actually be made and searched without success for the words to go with the drawing I just dived in anyway.

Turning the stocks from 1" square on the Boxford, first time I've used the fixed steady. Parting was interesting.

Turning the curve on the buffer head using Baggo's excellent tip, very roughly wound spring against saddle from tailstock and saddle disconnected from leadscrew.

The heads were turned from 1" en8 on the Boxford and just this last bit done on the little Chinese jobby, that topslide is a joke and seldom mounted.

A finished pair - I made 5 (doesn't everybody start an extra one to allow for oopsies?) and they all came out

Fitted and looking good imho. Buffer beam drilled and tapped 6ba with reduced head bolts, except one is a dummy because the hole has half of my 6ba taper tap in it. I bent up some links from 1/8" bms for the coupling.

After I had finished them the words appeared in the Q1 series, except the design had changed and was now fixed from behind the buffer beam - oh well