|

|

Post by Jim on Jul 10, 2010 6:02:01 GMT

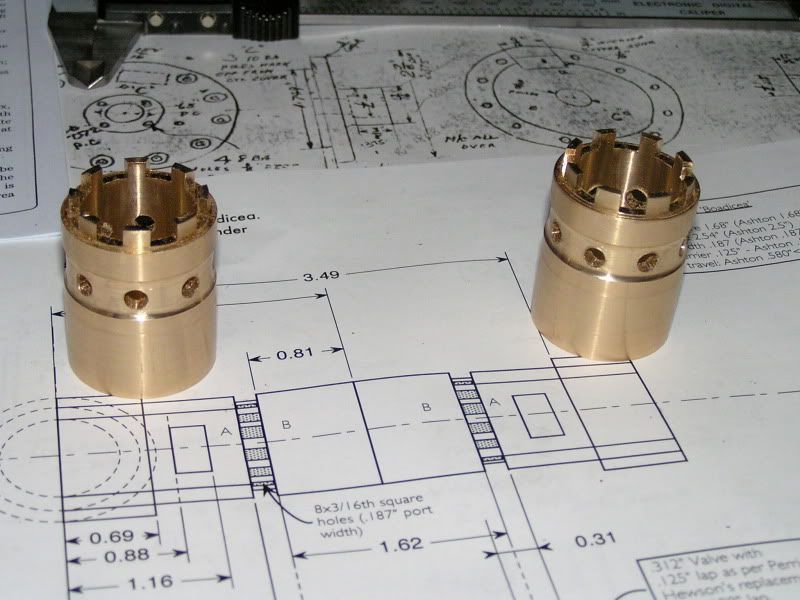

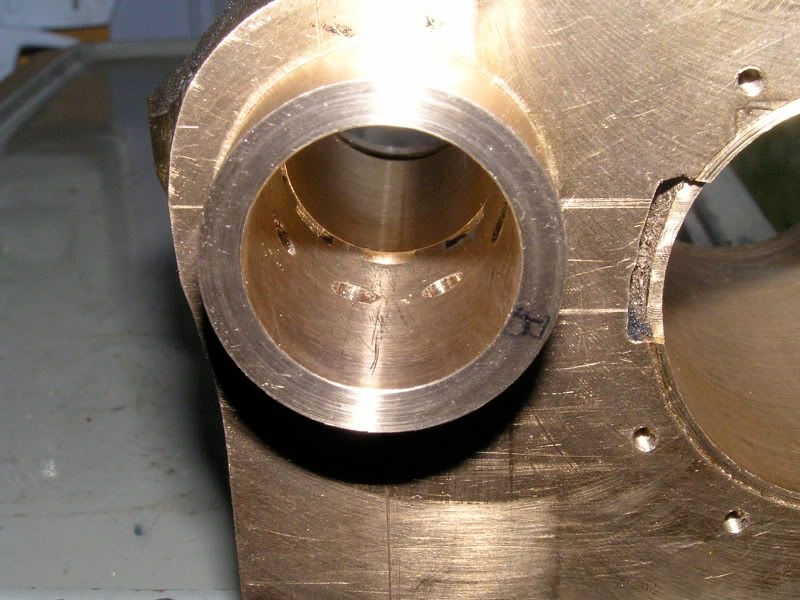

The completed valve sleeves for the piston valves have now been machined and pressed into the bore for the valves in the cylinder block. To ensure nice clean square inlet ports I made each liner in three parts (2 ends and a centre section) with the two ends having the open ended inlet ports. The ends were then pressed up against the centre section to complete the square opening of the ports. This method has been around for a while and described in various model engineering mags and I must say I am happy with the end result. Jim.   |

|

|

|

Post by baggo on Jul 10, 2010 7:46:42 GMT

Hi Jim,

It's interesting you've posted about the three part valve liners. I've got some to make for my brother's S15 and I was going to make them this way. I first read about it in one of LBSC's Lobby Chats written back in the 30's IIRC. It seems such an easy way to make them compared to the one or two piece methods usually described.

Do you intend to ream or hone them now they are fitted to ensure the bores are exactly in line? Maybe you already have.

John

|

|

|

|

Post by Jim on Jul 10, 2010 13:24:01 GMT

Hi John,

Yes, I reamed them after fitting them then honed them to get a nice smooth surface. The hone I used was one I got some years ago from the local Auto Cheap, I think it was intended for honing brake cylinders.

I forgot to mention that before pressing in the mid section I made a spacer/stop to make sure that it was correctly centered. The spacer also ensured that the centre section didn't move when I pressed the first end in to butt up against it.

It certainly is an easy and neat method for making the sleeves.

Jim

|

|