|

|

Post by Tel on Dec 5, 2010 6:09:30 GMT

|

|

|

|

Post by Tel on Dec 10, 2010 10:21:06 GMT

|

|

|

|

Post by jgb7573 on Dec 10, 2010 18:12:21 GMT

Nice!

|

|

|

|

Post by ettingtonliam on Dec 14, 2010 11:00:48 GMT

How big is it? I'm curious how you managed to carve out the inside of the water hopper.

Richard

|

|

|

|

Post by Tel on Dec 15, 2010 0:47:00 GMT

3/4" bore by about 7/8" stroke. The flywheels are 3 1/2".

;D The hopper was a bit of a trick! Actually you cut the top opening and drill down to depth with a biggish drill, then insert a cuts-both-ways boring tool inside and undercut it as far as you dare - obviously leaves a round chamber under the square mouth, but not really noticeable. The same method is used to cut the water journal that encircles the 'wet sleeve' liner.

|

|

|

|

Post by Tel on Dec 15, 2010 8:23:37 GMT

Today the carby.   |

|

isc

Statesman

Posts: 708

|

Post by isc on Dec 15, 2010 11:36:48 GMT

You could square a fair bit of the hopper using aT-slot/ Woodruff key cutter, whether it matters or not is up to whether you want to increase the water capacity. It looks good so far. Are the fly wheels iron or aluminium?isc

|

|

|

|

Post by Tel on Dec 15, 2010 16:50:08 GMT

Flywheels are cast iron - I hogged 'em out of a big old ci roller out of a dough rolling machine - now if only I had something to do with a bucketful of ci chips!

|

|

|

|

Post by Tel on Jan 3, 2011 8:26:03 GMT

Another progress shot - I haven't been totally idle!  |

|

|

|

Post by drjohn on Jan 3, 2011 10:16:10 GMT

Did you cut those gears, Tel? If so, they're awffy good!

DJ

|

|

|

|

Post by Tel on Jan 3, 2011 11:17:28 GMT

Yeah, the set that are on the engine I cut back last November, the second set I cut today.

|

|

|

|

Post by drjohn on Jan 3, 2011 11:24:35 GMT

What would the sycophants here say - "amazing - how did you do it, etc"

I just say you're not as daft as you look with your pith helmet! ;D ;D

DJ

|

|

ewal

Part of the e-furniture

Happiness is a good wife & a steam engine.

Happiness is a good wife & a steam engine.

Posts: 293

|

Post by ewal on Jan 5, 2011 16:34:09 GMT

Good on you Tel, That is beautiful. Put it on the sideboard.

E.W.

|

|

|

|

Post by steammadman on Jan 6, 2011 18:43:53 GMT

you trying to get him a devorce , or made homeless, ewal or as we say in our part of the world "CHUCKED OUT"

|

|

isc

Statesman

Posts: 708

|

Post by isc on Jan 7, 2011 12:19:42 GMT

Looks good, stick a pump on it and send it up to Queensland, I hear they'v got a bit of water they want rid of. My sympathy to any modlers caught up in the flooding. isc

|

|

|

|

Post by mogenskilde on Feb 19, 2011 11:30:36 GMT

Hi Tel

I like your work too.

For the moment I'm working on a dividing tool for gear cutting, did you take any photos of your setup for the cutting af your gears ?

Mogens

http://m_kilde.skysite.dk/

|

|

|

|

Post by Tel on Feb 19, 2011 20:33:15 GMT

I did take a few Mogens - I'll put some up shortly.

|

|

|

|

Post by Tel on Feb 19, 2011 20:43:27 GMT

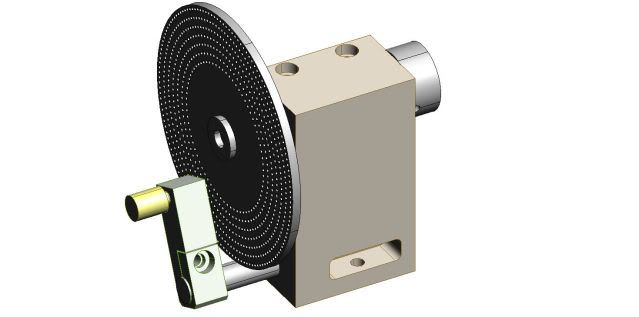

The dividing head is Harold Hall's 'simple', as described in both his 'Milling' and 'Dividing' books. I notice there are 15 photos in the series, so I'll put up the link. entertainment.webshots.com/album/579410844ASzYpvAny questions, feel free to ask - not that I'm an expert by any means, but I've done a few.  |

|

|

|

Post by mogenskilde on Feb 20, 2011 12:58:50 GMT

Hi Tel Thank you very much for the photos, usefull input it is. My design will be like this :  I think you got an arbor holding shafts in your tool, I'm thinking of making a threaded hole to take shafts, and maybe a support stock for the free end of the shaft. Also I have made modification to a drill chuck to hold smaller pinions, I might get back with questions when I'm getting a little further with the project. Thank you again Mogens http://m_kilde.skysite.dk/ |

|

|

|

Post by Tel on Feb 21, 2011 6:35:29 GMT

Yeah Mogens, mine takes either 2MT collets or the Myford chucks or faceplates. Also, of course, the 2MT mounted drill chuck on occasion. Your idea will work ok but it would be a good idea to split the spindle bearings, as has been done on mine - the rear one is adjusted and locked at the normal running condition, the front one locks the spindle up tight once you have indexed into position.

|

|