|

|

Post by swgwm02 on Sept 29, 2006 21:30:25 GMT

Do any members have some tips on forming the seats on ball valves as used in clacks and pumps etc.No matter how careful I am hitting the ball against the seat,when I check the seal by blowing there is always a slight annoying hiss.

I have been lucky on occasion and some seal really well. I have even used a brass rod guide as advised in model engineering books etc. Perhaps there is an easier method ?

|

|

|

|

Post by Tel on Sept 30, 2006 9:35:34 GMT

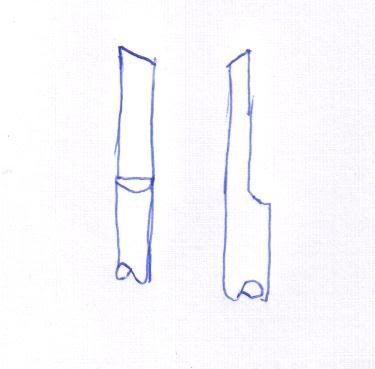

The only trick is to put a little rake on the front of the D-bit you use to bottom out the hole - as per the below rough sketch. This leaves the ball sitting atop a slight cone & will give you a much better seat I rarely ever have trouble with gettin' 'em to seat properly.  Angles exaggerated. |

|

|

|

Post by swgwm02 on Sept 30, 2006 14:13:52 GMT

thanks for the info Tel,will try this method next time  |

|

|

|

Post by Nigel Bennett on Oct 2, 2006 12:15:13 GMT

Rubber balls have always provided me with a complete solution!

Alternatively there are a few O ring seat designs around that should offer similar performance, but will require modification of the valve to suit.

|

|

|

|

Post by houstonceng on Oct 6, 2006 18:06:47 GMT

Turn up the seat separately and screw it into the clack (etc) - means changing the design a little. Form it as a taper (easier as a turning job to acheive the profile than as per Tel's "D" bit)

Trun the seat to a good knofe edge and ream the hole. Then put the ball to be used on the seat and polish it (the seating) by using the ball (loke a ball point pren) to draw figures of 8 on a thick newspaper (The Telegraph is good)

Test seating by sucking ball onto seating. If you can stick the assembly to your tongue using the vacuum created - you're there.

Assemble seating into fitting and steam-up.

Re-cutting the seating is easy and when you finally need to re-new it you don't have to make a complete fitting. Another advantage is that if you get "crud in the clack" (a very common and painful disease) you can remove the seat easily to clean the fitting out.

|

|