|

|

Post by fordfocus54 on Jun 18, 2014 19:17:27 GMT

I've been told that someone in the past had an article published in the model engineer which described modifying the ashpan on a Britannia to be removed completely from the loco by sliding it out sideways.

Does anyone have a copy of this which they could email to me?

Thanks

|

|

|

|

Post by Jim on Jun 20, 2014 12:49:27 GMT

Given the ash pan sits between the frames I can't see how it can slide out sideways. Is it possible you're referring to the grate? On Boadicea I decided the shutter style grate was fraught with problems so modified the ash pan to a chute style and opted for a rosebud grate that slides out to the left hand side of the boiler. If you didn't wish to have a rose bud grate I'm sure a standard on piece grate would work equally well. The photo shows Boadicea's grate in the 'half out' position.  Hope this helps Jim |

|

|

|

Post by fordfocus54 on Jun 23, 2014 20:33:55 GMT

Thanks Jim for your reply and very clear photo, I like the idea of being able to draw the grate out as any problems with this in the future would mean a strip down and boiler off to get at it.

Having not seen the ME article I don't know what the writer had done with his loco. It's a few days since I posted the request and with the exception of yourself no one has replied so perhaps I'll never find out!

|

|

|

|

Post by Jim on Jun 24, 2014 1:23:37 GMT

Hi Fordfocus,

Now you mention it I seem to recall the article being mentioned. However I still think they may have been referring to the grate as I mentioned earlier.

If I can be of any further help please feel free to contact me.

I have a photobucket site (see below) that has a record of building Boadicea. Not much has happened of late due to various factors but if I put my mind to it I could have the boiler completed in a couple of days, it's that close to completion.

Cheers

Jim

|

|

|

|

Post by Deleted on Jun 24, 2014 8:23:46 GMT

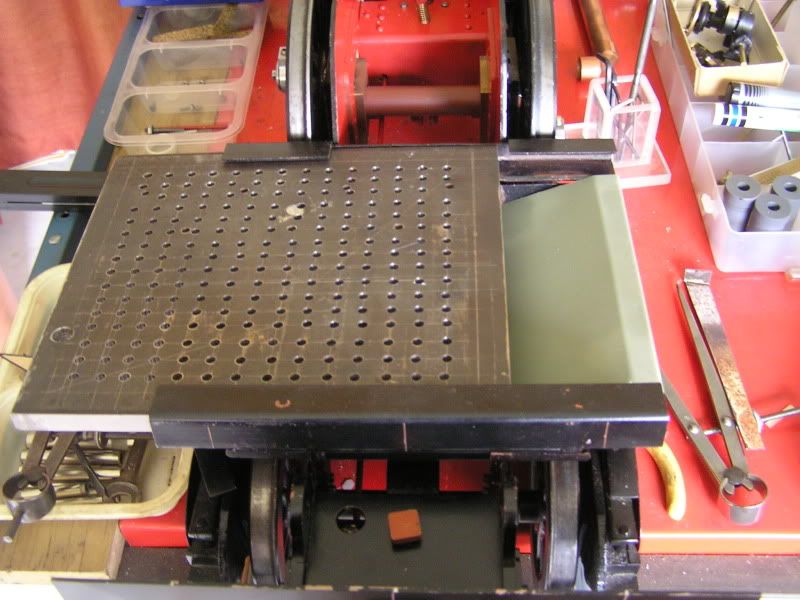

This photo shows the ashpan and grate of my Modelworks Britannia (I've since moved the rather ugly brass trunnion inside the side plate).  The grate has three hinged sections. These are not entirely satisfactory because they do not drop reliably of their own accord when the pin is pulled because bits of coal get wedged in. They need vigorous prodding through the coal hole to get them down to clear the grate. In an emergency, eg a broken gauge glass, it would be difficult to drop the fire quickly. I think it would be easy to modify the grate to eliminate the dropping sections, and then to modify one side of the ashpan so that the upper part with the grate attached could be pulled out. Some slides or supports for the grate as Jim suggests would help to reinstall it. The injector pipework would need to clear the removable section. A possible downside is that the grate might still be difficult to remove because coal might jam between the grate and the inside of the firebox. I've thought about doing this if I ever have occasion to remove the boiler. Regards, John |

|

|

|

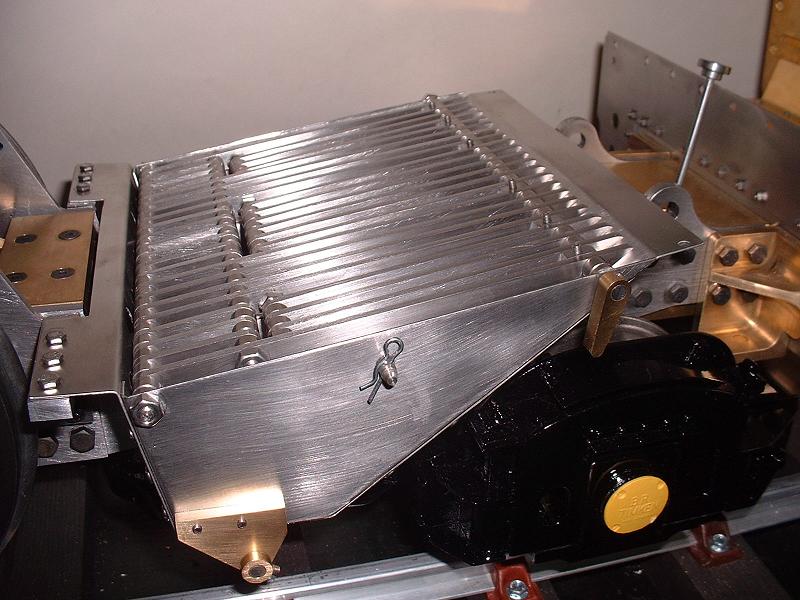

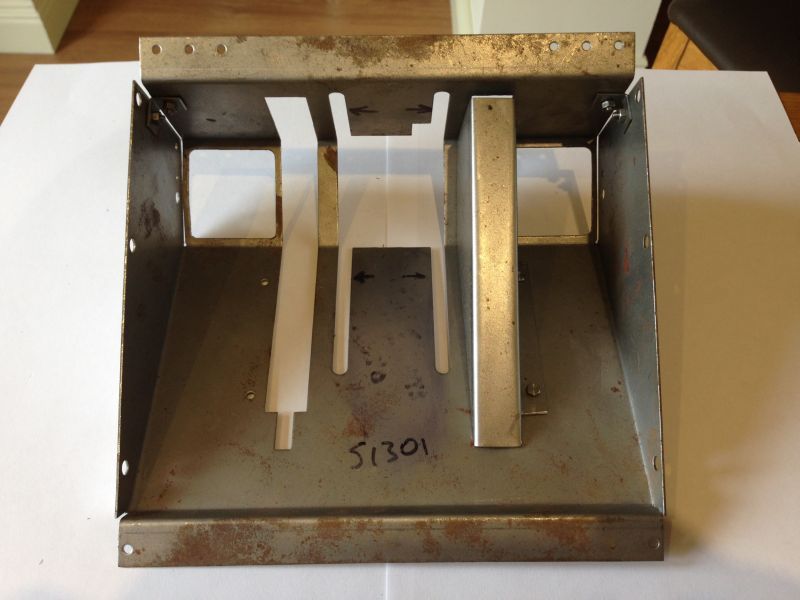

Post by Jim on Jun 24, 2014 10:16:14 GMT

Following on from John's comment on the ash pan shutters this is the modified ash pan that I came up with. I might add that after these photos were taken I added some draft holes to the front of the ash pan.   Burning char as we do here in Oz and with a rosebud grate the ash left is fine dust that just drops through the holes in the grate and onto the ground. If this was a problem a simple swing type shutter could close off the chute in the base of the pan to retain the ash. John raises a good point in that small bits of coal/char could jamb the grate as it is slid out. To prevent this I will use a flat strap that will double both as a 'pusher' for sliding the grate out and as a poker for clearing any obstruction between the grate and the foundation ring. There's lots of ideas on this site and John has a very detailed blog covering his Britannia build which is a great source of information. Jim |

|

|

|

Post by Deleted on Jun 24, 2014 12:38:18 GMT

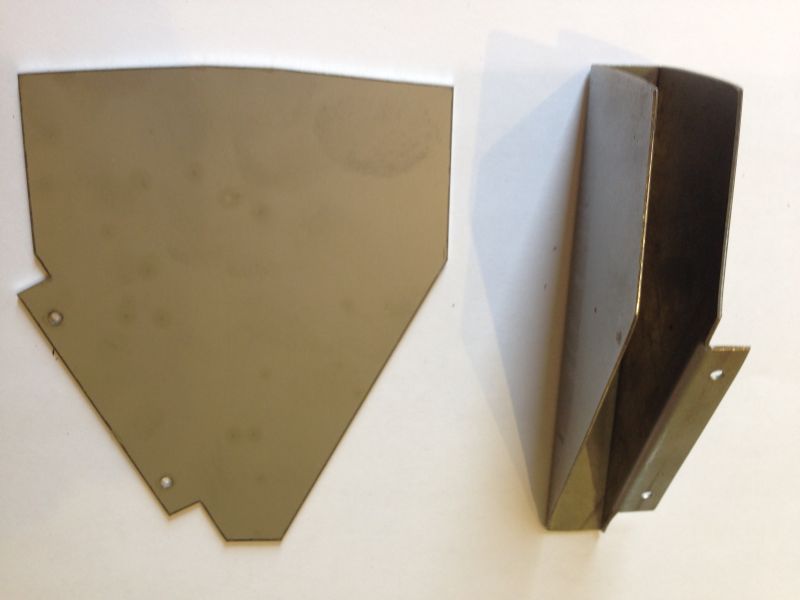

Here's a photo of a well-used Britannia taken at my club a few years ago, showing the grate removed from the side after steaming:  The injector output feed seems to avoid the ashpan by going to the backhead rather than the top feeds. Regards, John |

|

|

|

Post by Jim on Jun 24, 2014 22:23:35 GMT

Thanks for that photo John. As I look at it I can see how I can run my injector pipes to clear the slide out grate without things looking too out of place.  Jim |

|

|

|

Post by fordfocus54 on Mar 31, 2015 21:19:37 GMT

Thanks to everyone who took the time to reply to my question. I have used some of your ideas to modify the ashpan from my 5" gauge Britannia which is Winson kit number 25, and sold in July 1999. I purchased it in April last year and have spent the last 11 months completely rebuilding it. So far I have got the chassis rebuilt and have tested it on air and I'm now on with the boiler cleading. I hope to have it running in 2016 As you can see the it now sports three drop down doors and the left side can be removed completely to slide the grate out if required.

I have also finished the firehole doors which have been modified with new mountings and GWR style doors. |

|

|

|

Post by Deleted on Apr 2, 2015 13:20:46 GMT

nice work there sir....

Pete

|

|

|

|

Post by trainman on Apr 2, 2015 15:11:08 GMT

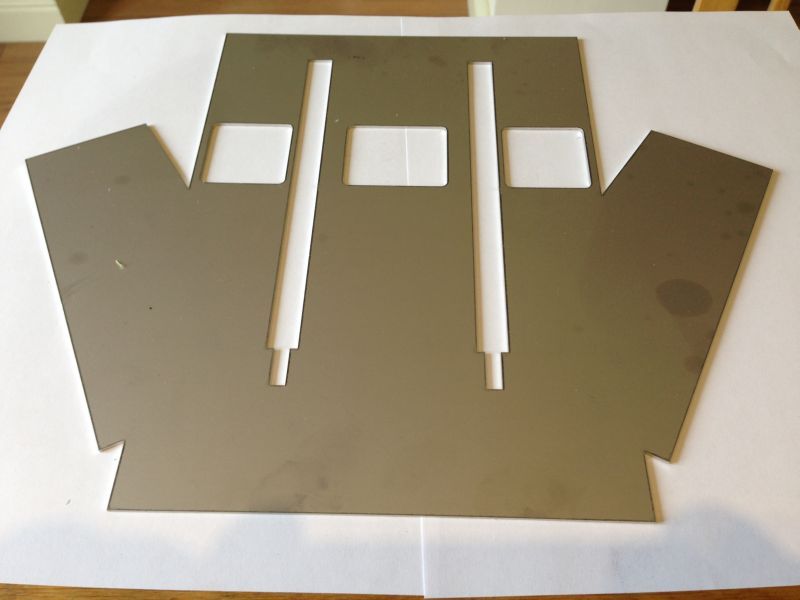

Hi Frank, That looks great. I have bought a stainless grate made from triangular cross section bar that I am going to adapt to slide in out as others have done, hopefully to make it easier to keep clean.  I have also had a new ashpan and the associated frame protection covers cut from 1.5mm stainless steel to ensure that they last longer.  Not bent them to shape yet, best to formulate plans on how to make it all fit together and work first! Then all the seams can be welded up.  Original Winson ashpan with one cover in place  I think the grate is slightly too small so will probably get a bigger piece rather than reduce the size of the grate area.  Paul |

|

|

|

Post by fordfocus54 on Apr 6, 2015 19:51:11 GMT

I have seen your grate material elsewhere and I think it's used as catalyst screen in industry. Being "V" shaped there may be less chance of the grate getting fouled with clinker and jamming between the bars.

Going back to my ashpan I still may modify the two bars that lift the two outside sections of grate to the horizontal position. You can see in the photo they protrude higher than the grate bars, and then its all too easy to contact the foundation ring and prevent the whole thing from working properly.

The kit has certainly saved me years of work but if you want to improve the original, and lets face it there's plenty to improve! It will keep me busy for quite a while yet!

|

|