|

|

Post by simplyloco on Jun 28, 2020 18:42:20 GMT

Very nice as usual. Mind you look out for the flak you will get as I did for putting a shiny handle on a lever!  John |

|

|

|

Post by springcrocus on Jul 2, 2020 8:20:42 GMT

One correspondent, Alan (jagmanal), sent me this picture of a Britannia firehole door. It may be of interest to anyone who would like to make more authentic firehole doors. It shows the vents very clearly.  Steve |

|

|

|

Post by David on Jul 3, 2020 11:14:12 GMT

Any thoughts as its something that has prevented me from designing taper spindles into my own scale water gauge castings there are sat here waiting for a cunning plan. Could you make something like a square, but not 90deg? Then use it to set the angle on the compound slide. |

|

|

|

Post by 92220 on Jul 3, 2020 18:17:12 GMT

The Swindon BR drawings I have for the firedoor arrangement and details, show the handle as a mild steel handle knob, welded onto the steel strip operating lever. All the photos I have for 9Fs show the handle as bright steel. All the levers are painted black. The drawing is applicable to both 9Fs and Britannias.

Bob.

|

|

|

|

Post by simplyloco on Jul 3, 2020 18:46:49 GMT

The Swindon BR drawings I have for the firedoor arrangement and details, show the handle as a mild steel handle knob, welded onto the steel strip operating lever. All the photos I have for 9Fs show the handle as bright steel. All the levers are painted black. The drawing is applicable to both 9Fs and Britannias. Bob. Hi Bob. Steve and I both know that: it's just that we like shiny bits!  And of course they are our own locos... John |

|

|

|

Post by springcrocus on Jul 4, 2020 6:35:31 GMT

The handle stays: there is much about this loco that is not authentic and another small detail matters not. There are four mudrings on the top of the firebox and two near the front of the boiler barrel. To make these, I started by parting off a load of 15mm copper tube into 5mm long rings. These were then squashed in the vice to form the oval shape and reformed at each end around 3/8" dia bar. A piece of 20 swg brass sheet was coated in flux, the rings rested on top and a piece of silver solder rested inside each ring.  Heat was applied from below the sheet until all the solder had melted. It naturally flows to the edges of the ovals and penetrates underneath. The picture shows the assembly a minute or so after the heat was removed.  Each of the mudrings was then cut from the sheet with a junior hacksaw and the edges linished. Meanwhile, a start was made on the mudhole bridges, with a pair of 2mm channels being milled into a length of 1/2" x 1/4" brass bar. The outer wall thickness is about seventy five thou.  To make each bridge the end of the bar was first cleaned up in the lathe...  ... followed by drilling the bolt hole on the mill.  These were then cut off with a hacksaw and put to one side. Once they were all finished, they were set in the milling vice and finished to 3/16" thick. Then they were loaded back to the vice and the legs formed by milling away the outsides as shown. This method allowed them to be upended and the other side done at the same settings, leaving the legs 1/16" thick. I kept the cutter at the finished depth and milled with the side of the cutter, 25 thou per pass. This endmill is one that I have ground for brass, it's just possible to see the flat on the corner of the cutter (same on all flutes) that stops it snatching.  Back with the soldered parts, an 8BA hole was drilled and tapped in the centre of each dummy mudhole and a bridge screwed to each. I haven't bothered to completely clean up the outside of these because they are never seen once they are soldered into the cleading.  Although I have done a small amount of filing on the bridges, I will probably round them off a little more before final assembly. I will also dress the protruding threads back to the base. Once soldered into place, they can be painted which will soften the look of them even more. Steve

|

|

|

|

Post by 92220 on Jul 4, 2020 7:56:02 GMT

The Swindon BR drawings I have for the firedoor arrangement and details, show the handle as a mild steel handle knob, welded onto the steel strip operating lever. All the photos I have for 9Fs show the handle as bright steel. All the levers are painted black. The drawing is applicable to both 9Fs and Britannias. Bob. Hi Bob. Steve and I both know that: it's just that we like shiny bits!  And of course they are our own locos... John Hi John. I hasten to add, my note was in no way meant as a criticism. I noted your point that there might be flak due to the polished handle. I was just pointing out that what you and Steve had done, was not done on a whim, but was in line with BR drawings, so that any criticism would show the criticiser didn't know what they were talking about. Sorry if I gave the wrong impression. Bob. |

|

|

|

Post by jagmanal on Jul 4, 2020 14:49:23 GMT

Just a small point, any handle or hand rail handled by the crew on a regular basis will end up polished by default, painting hand rails are a regular winter maintenance job. So in short the firehole door handle will always be shiny whether you like it or not

|

|

|

|

Post by springcrocus on Jul 5, 2020 6:29:35 GMT

I made the bracket for the speedo from 1mm mild steel sheet but I am using the castings supplied by Adam Cro for the rest of it. The bracket was cut at 2" x 1" and marked out for removing the side sections.  The holes were drilled first and I have made the two tapped holes 12BA instead of 10BA because of restricted space on the casting. Then the bracket was held edge-on in the vice and the sections removed with a 1/8" dia end mill.  The speedo head had a 1/4" hole drilled and reamed through to match the pivot pin on the wheel. The top of the head was drilled and tapped 12 BA and a retaining screw fitted which locates into the groove of the pin and stops the speedo head falling off but allows it to rotate. The other end was drilled and tapped 10BA and a stud screwed in to act as a register for the flexidrive pipe.  Nowadays, these castings are supplied with seven M1.0 screws to fit the covers but when I bought mine these weren't included. I don't fancy messing about with screws this small, anyway, and used 1/32" dia brass rivets to fix them on mine, drilling 0.8mm in the body and 0.9mm in the covers, just in case of an alignment issue. I'm pleased to say that the cast-in dimples are exactly matched and assembly was extremely easy.  I've noticed that many choose not to include the speedo but I think it adds to the model. The prototype didn't have a speedo fitted until 1960 and, by then, had many other modifications including the smoke deflector hand-holds but mine is based on no particular year or period, just a mish-mash of features as I see fit. Steve |

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Jul 5, 2020 6:52:18 GMT

Steve

Great work as usual. Machining question. On the dummy mud rings you milled the bar on the lathe rather than your mill. Any particular reason? I am always interested in alternative methods.

Dave

|

|

|

|

Post by springcrocus on Jul 5, 2020 7:07:08 GMT

Steve Great work as usual. Machining question. On the dummy mud rings you milled the bar on the lathe rather than your mill. Any particular reason? I am always interested in alternative methods. Dave Dave,

Just a standard production-line technique, saves having to keep changing the setup. Different machine for each operation to keep the work flowing along.

Regards, Steve

|

|

Tony K

Elder Statesman

Posts: 1,574

|

Post by Tony K on Jul 5, 2020 7:10:49 GMT

The Swindon BR drawings I have for the firedoor arrangement and details, show the handle as a mild steel handle knob, welded onto the steel strip operating lever. All the photos I have for 9Fs show the handle as bright steel. All the levers are painted black. The drawing is applicable to both 9Fs and Britannias. Bob. Hi Bob. Steve and I both know that: it's just that we like shiny bits!  And of course they are our own locos... John Yes, they are your own locos - and you can do anything you like, without any criticism from anyone or having to justify anything you do. |

|

|

|

Post by Cro on Jul 5, 2020 7:45:07 GMT

Great work Steve, always interesting to see how people do it, I like the solution with the groove and screw it’s another I can suggest (and point them here for an example) if people ask ‘how do I do this bit’ and my usual response is ‘however you like but you could try xyz....!’

If you has said about the screws I’d have sent you some!

Adam

|

|

|

|

Post by springcrocus on Jul 5, 2020 8:28:02 GMT

... If you has said about the screws I’d have sent you some! Adam I know you would have, Adam, but I tell the truth when I say I don't want to work with screws that small. I would have needed to purchase a tap and, after sneezing, ask you for even more screws. I will not go smaller than 12BA; if it needs something smaller it gets a rivet or glued.

Regards, Steve

|

|

|

|

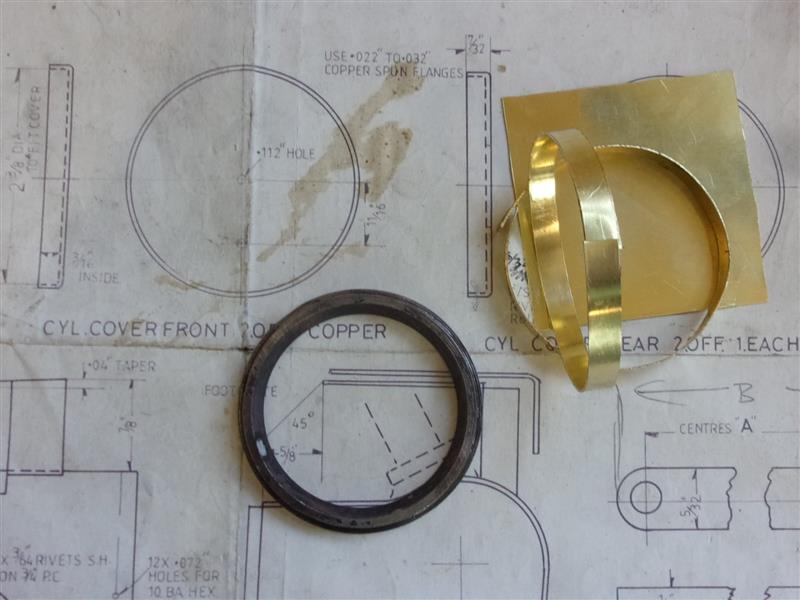

Post by springcrocus on Jul 15, 2020 7:40:23 GMT

The drawing suggests making these from thin copper sheet and spinning the flanges. I've not had great success with spinning so, following the ease of making the mudhole covers, I decided to adopt the same procedure. I have used 24 swg brass sheet because I have a reasonable quantity of it in stock. They need to have at least 3/16" depth inside the cover so I cut four strips 1/4" wide by 7.9/16" long, four plates 2.9/16" square and made a former to clamp the strips around. The diameter of the former is 2.3/8", the same as the cylinder end caps, and is 5/32" long with a locating shoulder at 2.1/2" diameter. The middle is bored away and tapered to help see what's going on when soldering.  The first strip was wrapped around the former and trimmed to length, the ends just butting up to each other, and a wire tie wrapped round to hold it firm. The bottom was then dressed on emery paper to give full contact when on the brass plate.  Flux was applied in a circle on the plate and the ring rested on top. Sections of solder were rested against the ring, some inside and some outside. I tried resting the workpiece on two blocks and heating from beneath but this failed dismally when the thin plate sagged in the middle. So, for my next effort, I just laid the assembly on an ash block and used a lump of flat bar to hold it down.  So this is what I ended up with. Because the ring is only 5/32" deep, there is a large enough gap at the bottom to stop the former being soldered to the workpiece, which can be prised out once the wire wrap is removed.  The corners were cut off and the outer shape dressed on the linisher, followed by a good polish with abrasive blocks and emery cloth. Most of this was done by putting the workpiece back onto the former and holding in the lathe. I chose to use soft jaws to minimize the chance of distorting the work. The penultimate job on the lathe was to dress the covers to length. For this, I added extra support with a centre and plate, then plunged to depth with the racking handle. Facing off in the usual manner would likely have deformed the thin section.  For the final lathe job, the two covers for the rear of the cylinders had the centre bored to 13/16" diameter to clear the piston gland housing. Then the chuck was removed and remounted on the mill so that the various holes could be drilled. Here are the final covers with the pressure relief valves fitted.  And here is the missing one mounted on the front of a cylinder. The loco is upside-down on the bench at the moment. The front ones are a nice spring-fit on the end plates so I decided not to drill the 6BA fixing hole on these.  These should be a silver colour so I will look into what can be done, maybe satin-chrome of something. If anyone else follows this procedure, I would recommend using a thicker gauge of brass sheet. This 24 swg material is quite flimsy and the few thou extra thickness of 22 swg would make a lot of difference. Steve |

|

|

|

Post by steamer5 on Jul 15, 2020 8:20:23 GMT

Nice work Steve!

Cheers Kerrin

|

|

|

|

Post by 92220 on Jul 15, 2020 8:27:29 GMT

Hi Steve.

Nice job! You can buy electoless, satin nickel plating kits from a number of places. Chronos do some kits, as well as others. I bought a kit to plate some brass pieces, to make them look like steel. Being 'electroless' it's an easy job.

Bob.

|

|

oldnorton

Statesman

5" gauge LMS enthusiast

5" gauge LMS enthusiast

Posts: 726

|

Post by oldnorton on Jul 15, 2020 8:27:47 GMT

These should be a silver colour so I will look into what can be done, maybe satin-chrome of something. Very good example of a thin metal fabrication wonderfully described, and good that the flat face did not distort when silver soldering. They would be nice in dull nickel plate, but that is a whole palaver of a plating system to set up. There are some aerosol paints that give a close approximation perhaps? Norm |

|

|

|

Post by silverfox on Jul 15, 2020 9:16:38 GMT

Steve

Thank you for the dummies guide to wash out plugs.

Duly noted to do eventually.

Ron

|

|

|

|

Post by springcrocus on Jul 15, 2020 15:22:15 GMT

Thanks for your suggestions, Gentlemen. Coincidentally, I was at the club this morning doing the annual portable appliance testing and one of the members suggested satin chrome paint from Halfords. I shall get a small tin and give it a try on some scrap. If not, it might be interesting to try electroless nickel plating just to find out how effective it is.

Regards, Steve

|

|