barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jul 15, 2020 16:59:43 GMT

Hi Steve, Humbrol used to do a paint called Metalcote. It went on like enamel but when dry could be buffed up to a shine. I seem to remember they did a nice gunmetal colour that could be just the job.

Mike

|

|

|

|

Post by Deleted on Jul 15, 2020 21:42:48 GMT

Hi Steve, Humbrol used to do a paint called Metalcote. It went on like enamel but when dry could be buffed up to a shine. I seem to remember they did a nice gunmetal colour that could be just the job. Mike Hi Mike I don't think Humbrol do the metalcoat range anymore but there are other model paints which do the same, in fact, they are better, alas the brand name fails me right now. There are also similar auto paints such as those available from Frost Restorations. Pete |

|

|

|

Post by Deleted on Jul 15, 2020 21:47:52 GMT

'Alclad2' is the name, they do a very large range of real looking metal finish paints

|

|

|

|

Post by springcrocus on Jul 15, 2020 22:03:17 GMT

Arrrrgh! It must be an age thing.  Guess what I found in the indoor playroom.  Satin bronze, polished steel, satin gold and gunmetal. It looks like I might be doing a spot of painting tomorrow. Thanks, Mike, for the nudge. Regards, Steve |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jul 15, 2020 22:16:02 GMT

You should put them on Ebay, they might be worth a fortune.

Mike

|

|

|

|

Post by springcrocus on Jul 17, 2020 8:05:20 GMT

There is little or no information on the drawings regarding plumbing the loco, just a vague sketch of where some of the pipes are supposed to go. The axle pump feed and return come into the "no" category and require some careful thought on routing to avoid the pony truck and the ashpan doors. I have made it more difficult by using 1/4" dia copper tube rather than the specified 7/32" tube. I couldn't find a supplier of the 7/32" tube who didn't require one to take out a mortgage. The pump end wasn't too difficult, just needing some compound bending to achieve the target.  Easing the pipework around the edges of the pony frame was harder but it just fitted against the sides and slightly into the gap by the ashpan. I've had to put additional clips on the pony frame to keep the pipes in place.  The other tight fit was between the pony truck and the frame but I managed to gain an extra millimetre by adding a washer to the kingpin. The pipes just clear the ashpan door hinge pins, so all is good.  Life could have been much easier if the centre section of the ashpan was made narrower or tapered, with a smaller central door, as there would have been a service space along the insides of the pony frames. Something any future builders might like to consider. Steve |

|

|

|

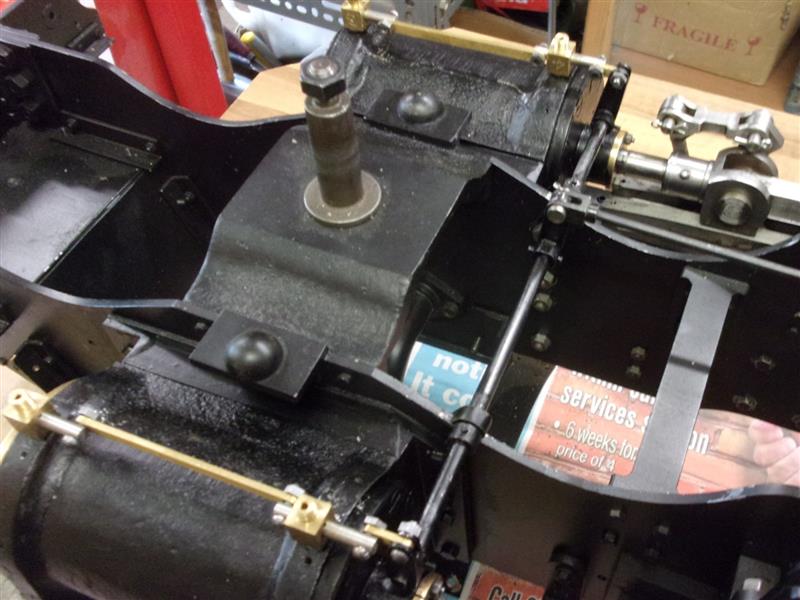

Post by springcrocus on Jul 19, 2020 16:36:05 GMT

Now that I'm on the home straight, as it were, I'm trying to finish all those small jobs on the underside so that I can put the loco back on it's wheels once and for all. Of course, this is doomed to failure but I will see how it goes. On trying to set up the cylinder drain cock operating mechanism, the first thing that became obvious was that the designer had got it wrong yet again: no suprise there, then. The holes in the mainframes for the cylcock shaft are too close to the cylinder causing the operating forks to foul the piston rod gland housing. This problem could have been avoided by drilling them much closer to the edge of the frames but too late now for me.  Rather than try to modify the frames at this late stage, I decided to make a pair of brackets to carry the shaft. These were made from 3/8" x 3/16" brass, drilled and reamed to take the 3/16" dia shaft and with a step milled to locate on the edge of the frame. They are held in place using the lowest of the cylinder backplate bolts.  The pull-rod was originally designed to pass through a slot in the ashpan but I welded this up when I saw how ridiculous the design was. I have been able to put a joggle in the rod behind the ashpan and an offset plate just to the front. This gives adequate movement to operate the drain cocks without resorting to a bowden cable or similar.  Here are the linkages fixed together at the front end. A turnbuckle in the operating rod allows for adjustment so that the limited travel of the valves can be set precisely.  I have checked with the front bogie in place and the clearance is sufficient so I can now strip the cocks off and get the cylinder cladding in place. Steve |

|

oldnorton

Statesman

5" gauge LMS enthusiast

5" gauge LMS enthusiast

Posts: 725

Member is Online

|

Post by oldnorton on Jul 20, 2020 8:27:34 GMT

Hi Steve,

You might find that the front bogie can swing enough to 'wipe out' the draincocks in the event of a derailment or miss-handling. I have fitted a retaining pin in the mounting stretcher and affixed a slotted extension to the bogie trunnion block.

Norm.

|

|

|

|

Post by springcrocus on Jul 25, 2020 8:21:07 GMT

Norm, thanks for that: I will follow your lead and do something similar. I had never got around to fixing the chimney to the smokebox and this was tackled next. To assist with this, I made a simple drill jig from an offcut of the boiler material and marked out the holes as shown. The outer row of holes is at the diameter of the flange and is for visual alignment.  A 6mm hole for a clamp was also put in the centre and then the plate was bent to shape, making sure the holes were in the correct orientation.  The holes were drilled freehand with one edge of the jig resting on the vice jaw and the back packed to get the plate level at the drill point, different heights being required for some of them. The drill jig is free to float around a little.  I keep telling myself that the outer row of holes were a carefully-designed aid to alignment but, actually, they were an extremely fortuitous cock-up.  The chimney was then set on the smokebox with the liner tube in place and the outer four holes spotted through. Because the four closest to the centreline of the smokebox sit under the rim of the chimney, I marked these with an angled scriber and centre-popped them.  All the holes were drilled as a generous 10BA clearance and 10BA threaded rivets (slotless dome-head screws) used to fix the chimney in place. I filed a little off the underside of the rivet heads to help them seat better on the angled face of the chimney.

I've yet to make the chimney liner / petticoat tube, the current piece of tube being used only as an alignment tool. Although I've had a kind offer of assistance from Julian in this matter, I want to try and design my own based on what I've learnt from others on here. If what I make works then great. If it doesn't, there is always plan B.

Steve |

|

|

|

Post by springcrocus on Jul 31, 2020 18:38:50 GMT

Because I decided to do away with the square-ended stays at the top of the firebox, I needed twenty-one dummy washout plugs and I have made these from 1/2" dia brass bar. First operation was to turn the two outside diameters, drill a 6BA tapping hole and part off to length. I have made mine a little shorter than the drawing suggests to reduce the chance of fouling on the cross-stays, with 5/32" under the head and a 1/32" thick flange.  For the second operation, I changed over to an ER25 collet and plunged the bore with a small HSS tool. Because one cannot control the depth with collets like this (except with a backstop bar), after tightening I touched the tool on and wound the compound eighty thou to set the depth.  The square plugs were made from 1/8" square brass, held in another ER25 collet. Because it is an eight-segment collet, it held perfectly well in the 3mm-4mm dia one. They were turned to 110" diameter by 3/32" long and threaded 6BA then parted off with the square section finishing at 0.105" long. These were then screwed into the plugs and pulled tight, followed by linishing the backs flat. The one at the bottom is finished.  The holes were marked out on the cleading and drilled next, using a stepped hole drill to make the 3/8" dia holes. A length of 4" x 2" was clamped to the table and a 1/2" hole drilled quite deep. The sides were then rested on the timber and the holes drilled freehand. Because Roger mentioned elsewhere that he never holds sheet materials whilst drilling, it is worth stating that these type of cutters cannot grab because of their geometry and also that the top of the cleading acts as it's own fence, resting against the side of the timber.  I drilled and shaped the mudrings at the same time and then soldered these to the cleading, setting them about 1/8" below the surface. I've rested a horseshoe of solder on each one prior to heating.  The dummy washout plugs were soldered in next, remembering that there are six high-level ones on the driver's side and only five on the fireman's side, offset a little forward of the others. This is what they look like on the driver's side although I have not put the mudhole door handles back in yet.  I now need to concentrate on finishing the top bit where the boiler barrel joins the firebox, I've been finding lots of reasons to avoid doing it until now. Steve |

|

|

|

Post by springcrocus on Aug 3, 2020 18:30:11 GMT

Finding another excuse for not sorting the top profile of the boiler, I made up a nice little valve for the blower. This is a kit of four body castings plus other materials to complete the valves. I made one change because they supplied brass rod to make the valve stem and I substituted stainless steel. I found it easier to machine the whole of the spindle complete before parting off.  The rest of the parts were straightforward turning although depths had to be controlled quite precisely. The wall thickness between the valve bed and the inlet port is only thirty thou or so. I have substituted ME threads for the American National Fine threads specified on the drawing and I also made a square end on the spindle for a positive drive for the handwheel.  Steam is taken from the manifold and passed through the dummy duplex valve before passing through my valve and on through the hollow blower stay. Here it is mounted on the cleading.  When Wilf and I were building the boiler, Adam chewed my ear about how unsightly and un-prototypical the pipework to the blower stay looked, spoiling the clean lines of the backhead. The suggestion was to run the pipe outside, as in fullsize. This is my compromise that uses the hollow stay but, effectively, hides the pipework from sight below the regulator with it passing behind the false backhead.  I think it's a reasonable compromise. Steve |

|

|

|

Post by springcrocus on Aug 14, 2020 8:59:26 GMT

After seeing what Chris (coniston) did regarding superheaters for his A3 rebuild, and with regard to Julian's comment about needing them, I have decided to make mine almost the same as Chris's. He kindly offered to lend me his bending tool but the ferry companies are charging blackmail rates for crossing the Solent at present so I made my own. My local stockist (Aalco) didn't have any 1/4" x 0.036" wall S316 in stock, but they did have 6mm x 1mm wall so I purchased a length of that instead. This turned out to be quite fortuitous as it meant I could change how they were made and assembled. After cutting four pieces at 1260mm long for the tubes, I made a simple bending former. This is a piece of 1" dia mild steel, skimmed to 25mm and with a groove 6mm wide and 13mm diameter at the lowest point. A piece of offcut is resting in the groove to check the size.  I couldn't be bothered to make a bending handle and just formed the hairpins freehand around the former. First, the tube was rested in the former at the half-way point and clamped with an engineer's clamp.  The two ends of the tube were then bent until they were parallel.  Next, they were slowly squashed into the former, using the vice as a press, until the tails started to cross over.  A piece of 13mm (well, 15mm actually, but 13mm would have been ideal) flat bar was placed between the tails and the squeezing continued until the tube was fully in the former.  This is how they look after the vice is fully closed and the packing removed.  They were then tapped forward with a hide hammer to release them from the former. I found, the same as Chris, that the stainless tube bends very easily and there is no visible distortion of the tube in the area of the bends.  And here are two of them sitting the wrong way round in the superheater flues as a size check.  I will be having two hairpins in each flue, held in a cruciform arrangement. More on this later.

Steve

|

|

|

|

Post by coniston on Aug 14, 2020 20:20:08 GMT

Nice one Steve, glad my method worked for yourself as well.

Chris D

|

|

|

|

Post by springcrocus on Aug 16, 2020 9:01:29 GMT

To keep the superheater elements spaced apart, I made up four discs from some stainless steel bar, turned to 28mm diameter with a 12mm hole drilled through and parted off about 3mm thick. Four holes were then drilled on a 19mm PCD to maintain the designed 25mm outer form.  These were then tested for fit and to get an idea of the overall shape and size of the element assemblies.  I don't fancy the idea of silver-soldering stainless tube so I have decided to screw some copper tails to the hairpins which will be silver-soldered to the respective headers. With the tubes already bent, it was easier to use my tailstock dieholder with a brass guide mounted in the opposite end to ensure the die was perfectly square to the tube. I am using a collet block to hold the tube to prevent damage.  The thread I am using is M6 x 0.75 for which I have both tap and die. The die is mounted back-to-front to maintain the normal lead on the thread. The other tail has already been threaded here.  I also decided to mill away some of the collars to allow flue gases to get past a bit easier so a 6mm carbide endmill was used to remove material between the tube holes. Mounting all four together on pins and flipping over in the vice made the job very quick.  And, finally, a shot of the tubes sitting in the flues with the crucifoms in place.  Tails and headers next. Steve |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Aug 16, 2020 9:19:19 GMT

It's such an education every time you post something on here, especially as you are building the same engine as me. It regularly go back over your thread and on your website so see how you have done something I am struggling with. Many thanks.

Mike

|

|

oldnorton

Statesman

5" gauge LMS enthusiast

5" gauge LMS enthusiast

Posts: 725

Member is Online

|

Post by oldnorton on Aug 16, 2020 10:26:28 GMT

Steve

Nicely made superheaters and very sensible use of tubing with a simple bend in the end, like Hewson's but you have managed a slightly bigger bore I think. I like the nice spacing that the 'cruciforms' give but it made me wonder about something. Without those cruciforms it would be possible to poke a cleaning brush down there occasionally, but impossible with them, and they might encourage ash build up perhaps? If the flues block it will be just the radiant part working.

So it is better to space them nicely, or let them rattle and keep them clean?

Norm

|

|

|

|

Post by springcrocus on Aug 16, 2020 11:09:38 GMT

Steve Nicely made superheaters and very sensible use of tubing with a simple bend in the end, like Hewson's but you have managed a slightly bigger bore I think. I like the nice spacing that the 'cruciforms' give but it made me wonder about something. Without those cruciforms it would be possible to poke a cleaning brush down there occasionally, but impossible with them, and they might encourage ash build up perhaps? If the flues block it will be just the radiant part working. So it is better to space them nicely, or let them rattle and keep them clean? Norm Norm,

Having never driven or maintained a loco at any time, I can't answer your question. However, I would question the need to use a flue brush to clean the tubes. After the fire is out and all is cold, I would automatically choose to blow any deposits straight back to the firebox and ashpan with an airline. And if the superheater tubes get gummed up with sticky tar-like deposits, then I expect, even with the cruciforms out, it would still be nigh-on impossible to clean them with a brush unless the elements were withdrawn.

The main job of the cruciforms is to stiffen the assembly and stop them sagging at the firebox end because there will be quite an overhang. Indeed, I may make two more and have three per assembly so that I can have one right near each end and one in the centre.

Hmm. Maybe an opportunity here to think about designing easy removal of the assemblies for maintenance purposes.

Regards, Steve

|

|

stevep

Elder Statesman

Posts: 1,073

|

Post by stevep on Aug 16, 2020 12:06:09 GMT

Steve, the flues definitely benefit from a brush out. I get pieces of coal stuck in the flues of my Rob Roy, and I am not sure an air line would dislodge them. And the amount of sooty deposits that come off with the brush (brass bristles) would also not, in my opinion, come off with just a blow through with an air line.

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,860

|

Post by uuu on Aug 16, 2020 12:29:49 GMT

If you have further supports up the flue, you'll need to make them a nice loose fit. They'll get cemented in with the flue deposits and will be the devil to get out.

Wilf

|

|

|

|

Post by Cro on Aug 16, 2020 13:08:51 GMT

As Wilf says you’ll find that it will gum up pretty quick and you won’t want to be taking superheaters out regularly as it’s just a mess in there.

You want to be encouraging hot gas flow through there, as much as I like the idea I fear you are restricting things. The only other thing to remember with blowing the tubes out is that the soot goes everywhere - all over your lovely axleboxes and bearing surfaces and places you can’t get to easily to clean.

Love the return bends though, I’m about to weld up my spear heads and if I hadn’t already done all this I’d be doing similar I think!

Adam

|

|