|

|

Post by Oily Rag on Sept 28, 2019 21:15:05 GMT

That looks superb, you've been busy! It's great to finally get a boiler and frame together and get the first impression of what it will finally look like. You can start to feel that the end of the project is actually possible now. |

|

|

|

Post by Oily Rag on Sept 28, 2019 21:35:14 GMT

Excellent work Gazza. How about some details of that lathe tool height gauge?

As time passed, a moment came when along came an for an old dial gauge MAM's father gave me in a box off of odd bits.

I scratched around for materials under the benches, used a diamond pad to slide the hardened tip of the dial gauge over to get a flat. Fiddled and checked and adjusted. Makes setups very fast and to the .01mm . No errors from rulers or verniers etc. Sharp tools spot on centre height make the job of chasing dimensions much easier ATMCO.   |

|

|

|

Post by Oily Rag on Sept 28, 2019 22:32:18 GMT

Excellent work Gazza. How about some details of that lathe tool height gauge?    |

|

stevep

Elder Statesman

Posts: 1,073

|

Post by stevep on Sept 29, 2019 8:46:32 GMT

Excellent - thanks. Have you locked the bezel in some way?

|

|

|

|

Post by Oily Rag on Sept 29, 2019 20:21:21 GMT

Excellent - thanks. Have you locked the bezel in some way?

No, it is fairly firm by itself. I do try to be careful to not bump it. |

|

|

|

Post by Oily Rag on Sept 29, 2019 20:32:25 GMT

To the bike frame room, onto the plate. I had to put 0.03mm brass shim under one wheel to stop it rocking, not too bad I thought.

Then slowly removed approx 1.10mm from the protruding fire box stays that will support the back of the boiler. Took some time with the die grinder and files, but I got it to 0.10mm along the top of the barrel and not listing to port or starboard. This took some hours of trial and fit and adjust, repeat numerous times.   A few things to sort out in the drawings before committing to 2D and metal cutting. Blast nozzle lead in and a 3 degree taper in the chimney and a few other details. The door dart bar has been changed to be removable which is not shown in this pic. Isambard approves of CAD. :-) A few things to sort out in the drawings before committing to 2D and metal cutting. Blast nozzle lead in and a 3 degree taper in the chimney and a few other details. The door dart bar has been changed to be removable which is not shown in this pic. Isambard approves of CAD. :-)

|

|

|

|

Post by Oily Rag on Oct 3, 2019 21:57:25 GMT

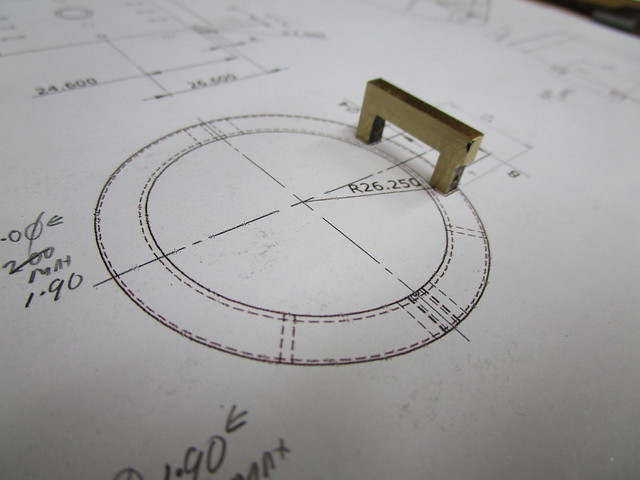

Simple stuff last night, making the boiler cab hold down clamps.

Both stay and clamps to be trimmed to fit and hold the boiler fire box protruding stays laterally and vertically. Maybe next week as I am off for weekend firing and driving at the www.maryvalleyrattler.com.au/

|

|

|

|

Post by Oily Rag on Oct 9, 2019 20:56:54 GMT

|

|

|

|

Post by Oily Rag on Oct 9, 2019 21:02:16 GMT

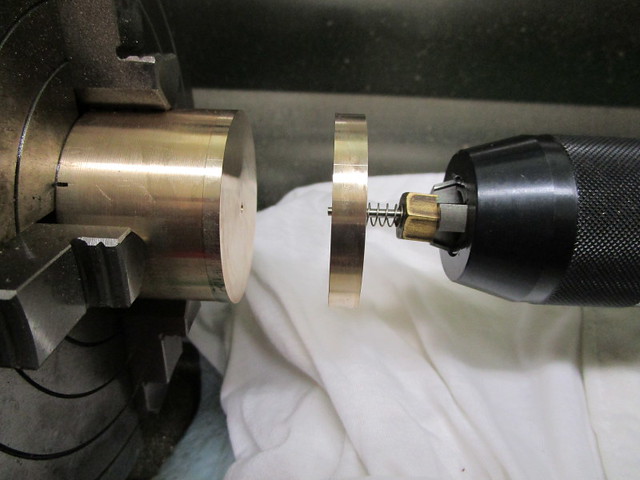

Set up the boiler in the frames with some Araldite last night to hold the saddle and smoke box barrel to ensure all is in a sweet alignment for drilling.Then started the set up under the mill drill.

I will have a sliding parallel under the end of the barrel to be sure while drilling and tapping all the holes etc. |

|

|

|

Post by Roger on Oct 10, 2019 7:25:06 GMT

The 'Rattler' event looked like a splendid affair and a reward for all of your efforts. You get back only what you put in is my mantra.

I really like the idea of Araldite to hold something in place for drilling. Simple but very effective.

|

|

|

|

Post by Oily Rag on Oct 12, 2019 11:08:36 GMT

The 'Rattler' event looked like a splendid affair and a reward for all of your efforts. You get back only what you put in is my mantra. I really like the idea of Araldite to hold something in place for drilling. Simple but very effective.

Fun days at the Rattler. I seem to get the good gigs without asking. I do my best to give respect to the job and people. Full trains as well during the school holidays.

It worked a treat, a bit of gentle warming and light tap with a small stick of wood and brave bingo.

The reason I did this was I then could line the boiler up and the smoke barrel and saddle in the frames. After the epoxy cured I fitted it up on the rotary table chuck and clocked off the base of the saddle. It made the drilling a treat and accurate. No elongated holes to allow alignments etc. Happy days. I sure I read about using epoxy in an ME article many moons ago.  |

|

|

|

Post by Oily Rag on Oct 12, 2019 11:13:39 GMT

A customer of mine gave me this book. A customer of mine gave me this book.

A legend in Horology. |

|

twombo

Seasoned Member

Posts: 120

|

Post by twombo on Oct 12, 2019 22:40:19 GMT

The 'Rattler' event looked like a splendid affair and a reward for all of your efforts. You get back only what you put in is my mantra. I really like the idea of Araldite to hold something in place for drilling. Simple but very effective.

Fun days at the Rattler. I seem to get the good gigs without asking. I do my best to give respect to the job and people. Full trains as well during the school holidays.

It worked a treat, a bit of gentle warming and light tap with a small stick of wood and brave bingo.

The reason I did this was I then could line the boiler up and the smoke barrel and saddle in the frames. After the epoxy cured I fitted it up on the rotary table chuck and clocked off the base of the saddle. It made the drilling a treat and accurate. No elongated holes to allow alignments etc. Happy days. I sure I read about using epoxy in an ME article many moons ago.  |

|

twombo

Seasoned Member

Posts: 120

|

Post by twombo on Oct 12, 2019 22:50:54 GMT

Wallace looks quite pleased! What is ‘Gromit’s ‘hands on hips’problem? The job site looks well in hand to me. Feathers seems to be. Standing out of the Fray. Health and Safety issues? Quite a crew you have here, Dazza!

Mick

|

|

|

|

Post by Oily Rag on Oct 13, 2019 21:42:50 GMT

Wallace looks quite pleased! What is ‘Gromit’s ‘hands on hips’problem? The job site looks well in hand to me. Feathers seems to be. Standing out of the Fray. Health and Safety issues? Quite a crew you have here, Dazza! Mick

Wallace is always pleased, he can see the joy in every thing, even a cockroach poo can have his arms up. However when Shunting this show of enthusiasm is often confused with the "stop" hand signal. This annoys drivers. Gromit is always pondering the tasks, he never stops thinking about how, when and the next step. Feathers McGraw and Preston are just tradies assistants, they can be quiet dim, but they work to instruction well enough, after all the are reformed criminals so management does not expect too much intellectually from them. |

|

|

|

Post by Oily Rag on Oct 13, 2019 21:52:34 GMT

"Shaun, management supplied this lump of LG2, they said make a smoke box door for the loco from this". "Where is Merv, has anyone seen Merv this morning ?"

|

|

|

|

Post by Oily Rag on Oct 14, 2019 21:32:04 GMT

"Hey Feathers, nice save on the 1.00mm holes for the pins, you nearly wrecked that centre finder by turning on the mill at 2500 RPM rather than 110 rpm you goose." "Preston, I am not a goose, I am a penguin this week!" "what ever you are this week Feathers, you are lucky management saved that expensive centre finder"

|

|

|

|

Post by Oily Rag on Oct 15, 2019 21:32:36 GMT

Wal is stoked, he has so far carried out management's plan for the door hinges. Also progress on the Smoke box door set up for machining. Trying out the Loctite holding process and so far so good, the workshop mob have never been down this road before."

|

|

|

|

Post by Oily Rag on Oct 16, 2019 20:55:11 GMT

The filling button collection is growing at the Llewellyn Locomotive Workshops. The smoke box barrel hinges parts are done.

|

|

|

|

Post by simplyloco on Oct 16, 2019 21:01:45 GMT

The filling button collection is growing at the Llewellyn Locomotive Workshops. The smoke box barrel hinges parts are done. Gosh, I wish that mine were that organised! John |

|